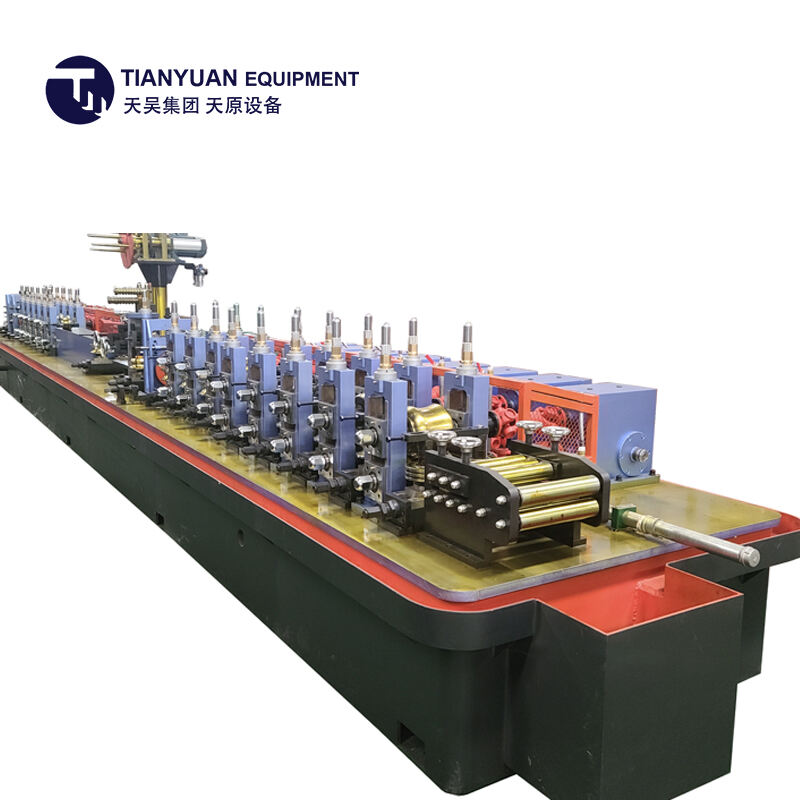

geavanceerde koolstaalete pipemaakmasjien

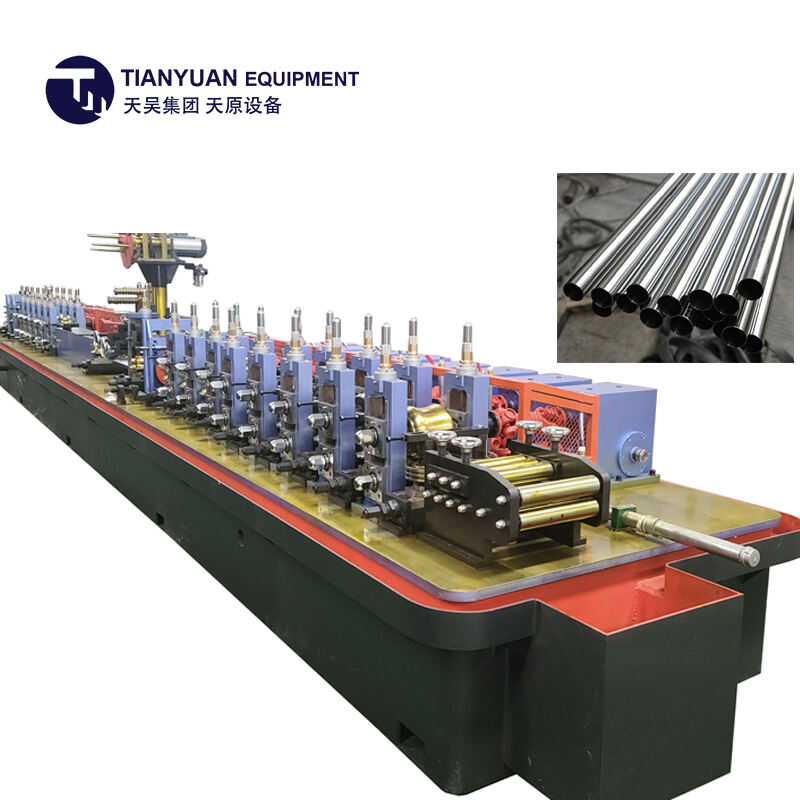

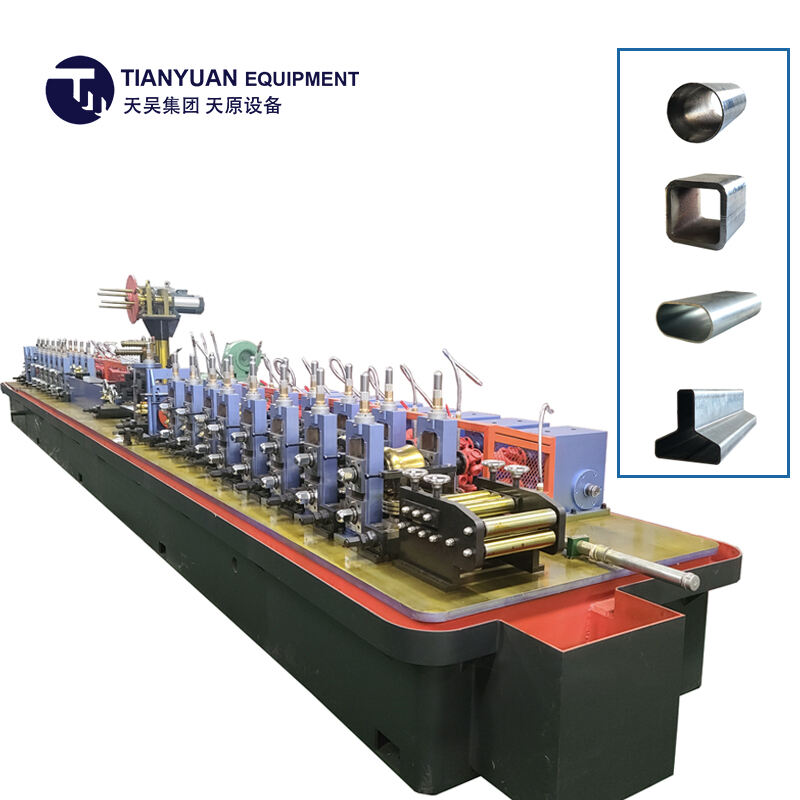

Die gevorderde koolstaaipypmaakmasjien verteenwoordig 'n snyskerpte oplossing in moderne vervaardigingstegnologie. Hierdie sofistikeerde toerusting integreer verskeie verwerkingsfasies in 'n gestroomlineerde produksielyn, wat in staat is om hoëkwaliteitskoolstaaipipes met presiese spesifikasies te produseer. Die masjien gebruik gevorderde outomatiseringstelsels wat alles vanaf materiaalvoeding tot finale produkonderhoud beheer. Sy kernfunksies sluit in materiaalvoorbereiding, vorming, weldeg, grootteaanpassing en afwerkingprosesse, alles wat deur presiese digitale beheers bewaak word. Die tegnologie het staatsvan-de-kunstweldstelsels wat konsekwente naadkwaliteit verseker, saam met outomatiese dimensiebeheerstelsels wat streng toleransies deur die hele produksie onderhou. Die masjien kan verskeie pypdimensies hanteer, tipies reikend van 20mm tot 219mm in deursnee, met wanddiktes van 1.2mm tot 8mm. Toepassings strek oor verskeie bedrywe, insluitend bou, olie-en-gasvervoer, industriële vloeistofstelsels en strukturele ingenieursprojekte. Die masjiens veerkragtigheid laat toe vir vinnige oorgange tussen verskillende pypspesifikasies, terwyl dit hoë produksie-effektiwiteit handhaaf en minimale materiaalverskoning verseker. Gevorderde sensors en kwaliteitsbeheerstelsels monitor die produksieproses voortdurend, versekerend dat elke pyp aan strenge industrie-standaarde voldoen. Hierdie toerusting behels ook energie-effektiewe stelsels wat kragverbruik optimeer terwyl maksimum produktiwiteit behaal word.