gi buis maakmasjien fabriek

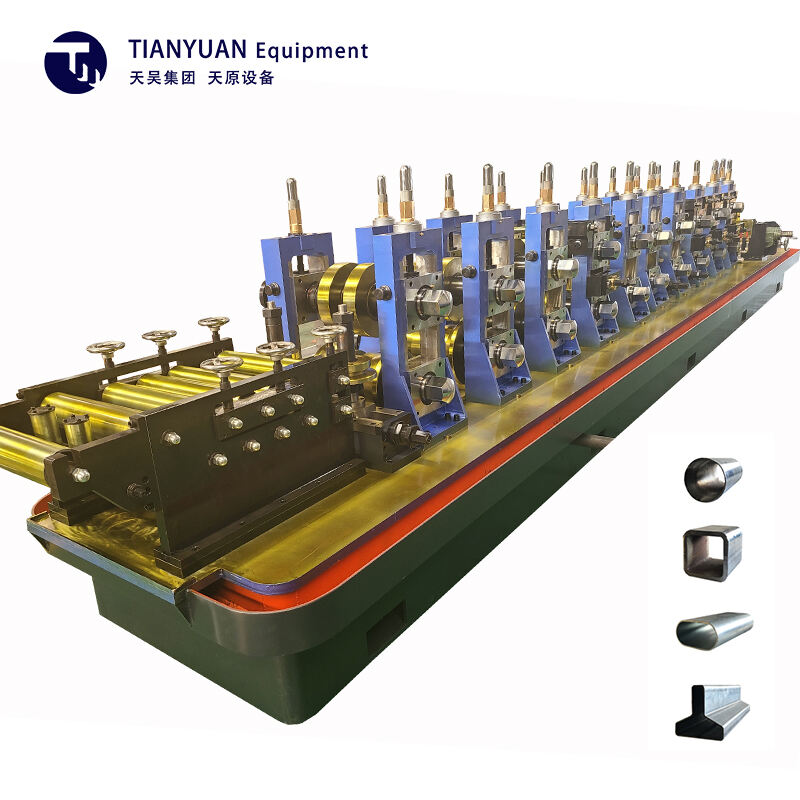

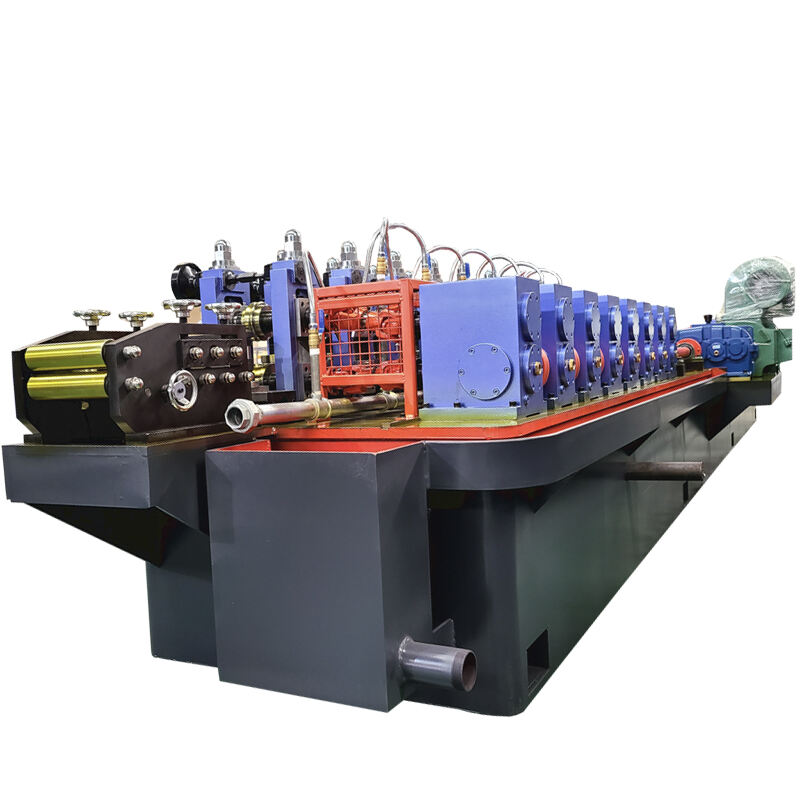

N gi-pyp vervaardigingswerf verteenwoordig 'n state-of-the-art vervaardigingsfasiliteit wat toegewy is om hoëkwaliteits galvaniseerde ysterpype deur geautomatiseerde prosesse te produseer. Hierdie gevorderde fasiliteite sluit snyrandtegnologie in, met presisie rolvormstelsels, geautomatiseerde skermstasies en gesofistikeerde galwanisasie-eenhede. Die werf funksioneer gewoonlik met meerdere produksielyne wat pype in verskeie dimensies kan vervaardig, van klein diameter pype vir woonhuiswaterleiding tot groot industriële pype. Die produksieproses begin met rowmateriaalhanteringsstelsels wat staalstrepe in vormmasjiene voer, waar hulle noukeurig in buisvorme gevorm word. Gevorderde skermstelsels verseker sterk, konsekwente naadlysies, terwyl die galwanisasieproses uitstekende korrosieweerstand bied. Kwaliteitsbeheerstasies uitgerus met ultra-geluide toetsing en röntgen-inspeksiestelsels bevestig die integriteit van elke pyp. Die fasiliteit sluit ook geautomatiseerde verpakkingstelsels en voorraadbestuursoplossings in vir doeltreffende produkhantering. Moderne gi-pypwerwe implementeer slimme vervaardigings Beginsels, IoT-senseurs en real-time toezichtstelsels om produksie-effektiwiteit te optimaliseer en konsistente kwaliteitsnorms te handhaaf. Hierdie fasiliteite het dikwels omgewingsbeheerstelsels om uitstoot te bestuur en werksplekveiligheid te verseker, saam met waterbehandelingsaanleg vir volhoubare vervaardigingspraktyke.