koste van ms-pyp vervaardigingsaanleg

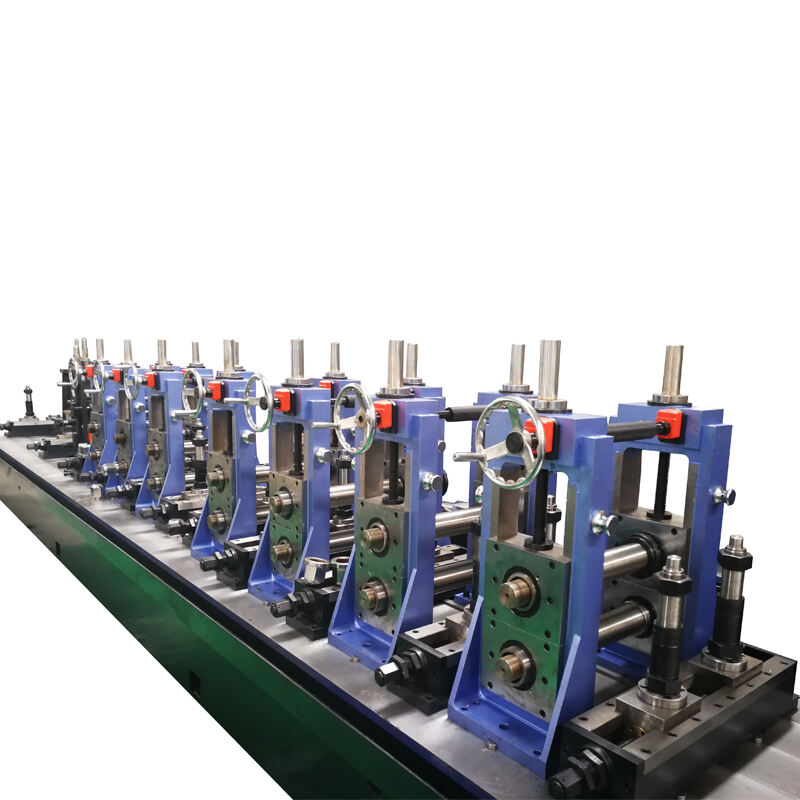

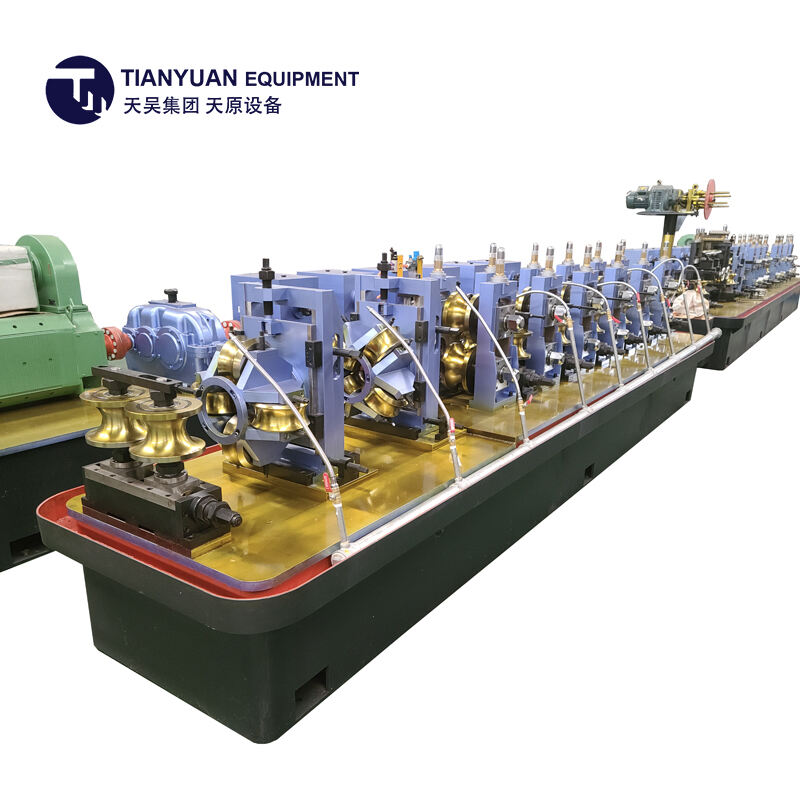

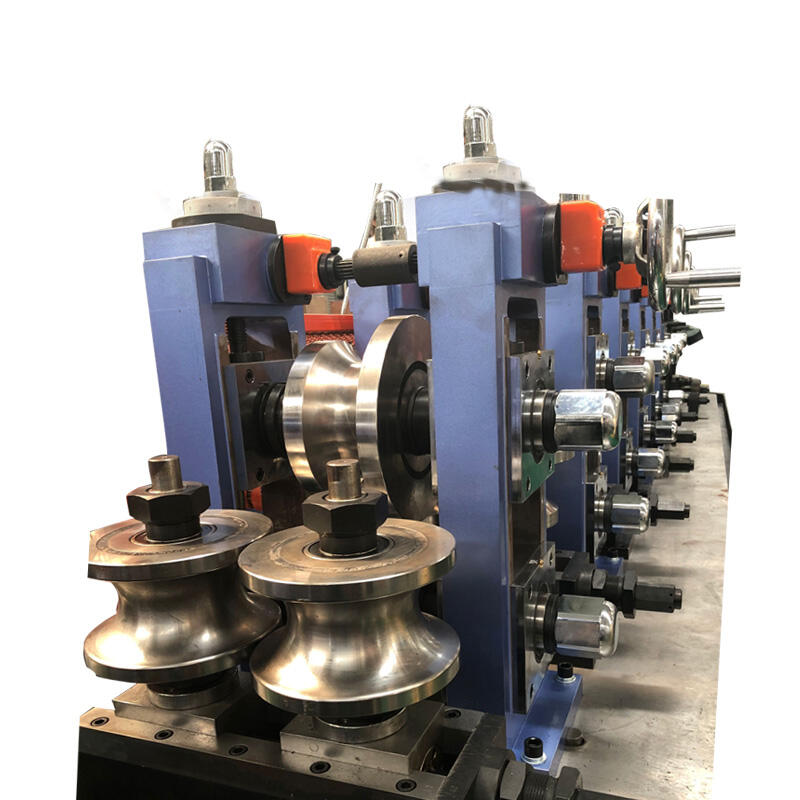

N MS (Mild Steel) buis vervaardigingsaanleg verteenwoordig 'n beduidende belegging in industriële infrastruktuur, met koste wat wissel volgens skaal en vermoëns. Die aanleg sluit tipies essentiële toerusting in soos ontrolmasjiene, lintvormingseenhede, skermstelsels, afmetingseenhede en snymechanismes. Aanvanklike opsetkoste strek van $100,000 vir klein-skaals operasies tot verskeie miljoen dollar vir groot industriële fasiliteite. Die kostestruktuur omsluit masjienerwerving, grondvereistes, utiliteitsopset, werkskrmutdanning en bedryfskoste. Moderne aanlegte kenmerk word deur outomatiseerde produksielines, kwaliteitbeheersisteme en gevorderde skermtegnologie om konsekwente produk-kwaliteit te verseker. Hierdie fasiliteite kan buise vervaardig wat varieer van 15mm tot 400mm in deursnee, met wanddiktes van 1.2mm tot 12mm, wat dien vir verskillende industriële toepassings. Die produksiekapasiteit strek tipies van 1,000 tot 50,000 metriese tonne jaarliks, afhangende van die aanleggrootte. Kosteoorwegings sluit ook in rooimateriaalhanteringsisteme, toetsingsuitrusting en omgewingskompliansiemeetowwe. Die ontwerp van die aanleg moet toekomstige uitbreidingsmoontlikhede akkommodeer en operasionele doeltreffendheid handhaaf om terugbetaling op die belegging te verseker.