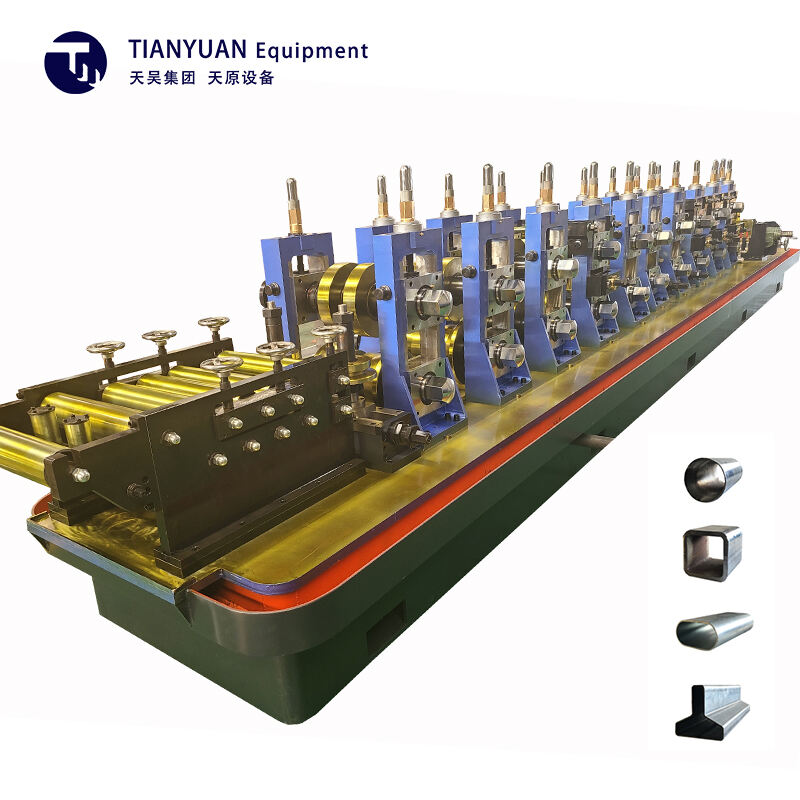

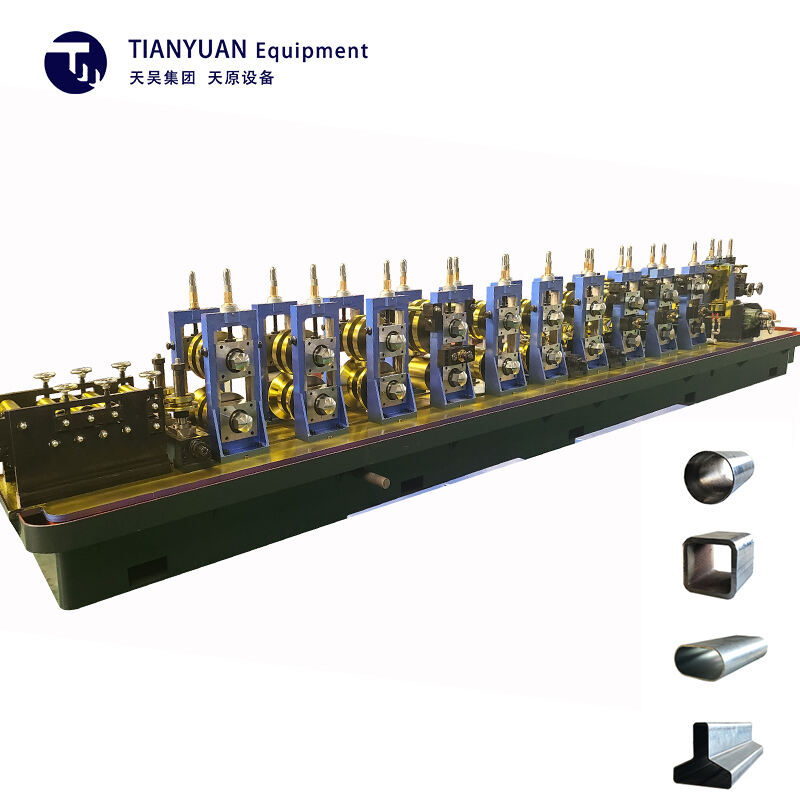

kwaliteit hf gesoldeerde buisrolmolen

Die hoë-frequentie gesoldeerde buisrolmlyn verteenwoordig 'n sn ebpuntige vervaardigingsoplossing wat ontwerp is vir die doeltreffende en konsekwente produksie van presisie gesoldeerde staalbuise. Hierdie gevorderde stelsel kombineer soekelektiese induksie-tegnologie met noukeurige meganiese ingenieurswese om hoë-kwaliteit gesoldeerde buise te skep. Die bedrywing van die mlyn begin met staalstrookverwerking, waar die materiaal deur 'n reeks spesialiseerde vormroele voorichtig in 'n buisvorm verander word. Die rande word dan met hoë-frequentie elektriese stroom op die ideaal gesoldeer temperatuur verhit, gevolg deur onmiddellike druksoldeer om 'n sterk, uniform voeg te skep. Die stelsel sluit gevorderde beheers in vir die onderhoud van kritieke parameters soos soldeer temperatuur, druk, en spoed, wat verseker dat die kwaliteit van die voeg konsekwent bly. Opmerkbare kenmerke sluit outomatiese dimensiebeheerstelsels, real-time voegmoniteringvermoëns, en geïntegreerde kwaliteitsinspeksie gereedskap in. Die mlyn kan verskeie staalgraderings prosesseer en produseer buise wat wissel van klein diameter tot groter groottes, geskik vir verskeie industriële toepassings insluitend bou, motor, en infrastruktuurontwikkeling. Moderne HF gesoldeerde buisrolmolens het ook verbeterde energie-effektiwiteitstelsels en digitale beheerinterfaces vir presiese bedrywingsbestuur.