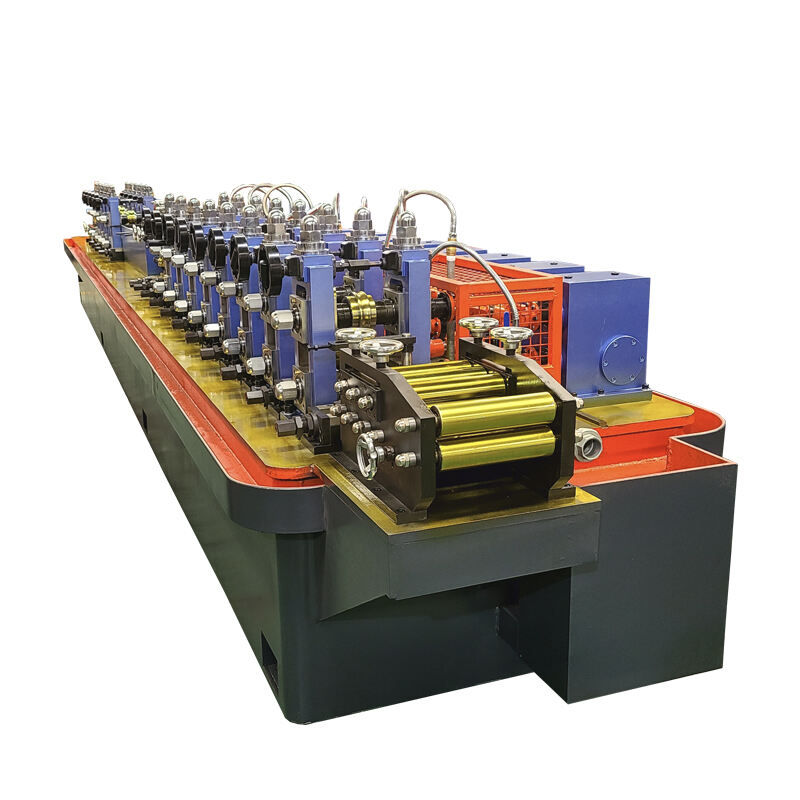

stabiele buisvormingsmasjien

Die stabiele buisvormingsmasjiene verteenwoordig 'n deurbraak in moderne industriële vervaardigingstegnologie, ontwerp om hoë-kwaliteitsbuise met uitsonderlike konsistensie en presisie te produseer. Hierdie gevorderde toerusting maak gebruik van snycoproll-forming-tegnologie om vlakke metaalstrepe in perfektement sirkulêre buise te verander deur 'n sistematiese, veelvoudige stadium-proses. Die masjiene het 'n sofistikeerde beheersisteem wat presiese dimensiekonstansie deur die vormingsproses onderhou, wat verseker dat elke buis presies aan spesifikasies voldoen. Sy robuuste konstruksie sluit harde staalvormrolle, presisie-ingenieerde gidsisteme en gevorderde weldebare-moglikhede in wat in perfekte sinchronisasie werk. Die masjiene kan verskeie materiaalle soos koolstaal, roestvrystaal en aluminium hanteer met diktes wat tipies van 0.5mm tot 6mm reik. Met bedryfsnelhede van tot 120 meter per minuut, sluit dit outomatiese kenmerke soos lengtebeheer, sny-na-lengtesisteme en kwaliteitsmoniteringsensor in. Die stabiele buisvormingsmasjiene is veral waardevol in bedrywe soos bou, motorvervaardiging, meubelproduksie en infrastruktuurontwikkeling, waar konsistente buiskwaliteit krities is. Sy versoepeling laat toe vir die produksie van sowel rond as spesiale-vorme buise, met middellyne wat van 20mm tot 200mm reik, wat dit 'n onontbeerlike instrument vir moderne vervaardigingsfasiliteite maak.