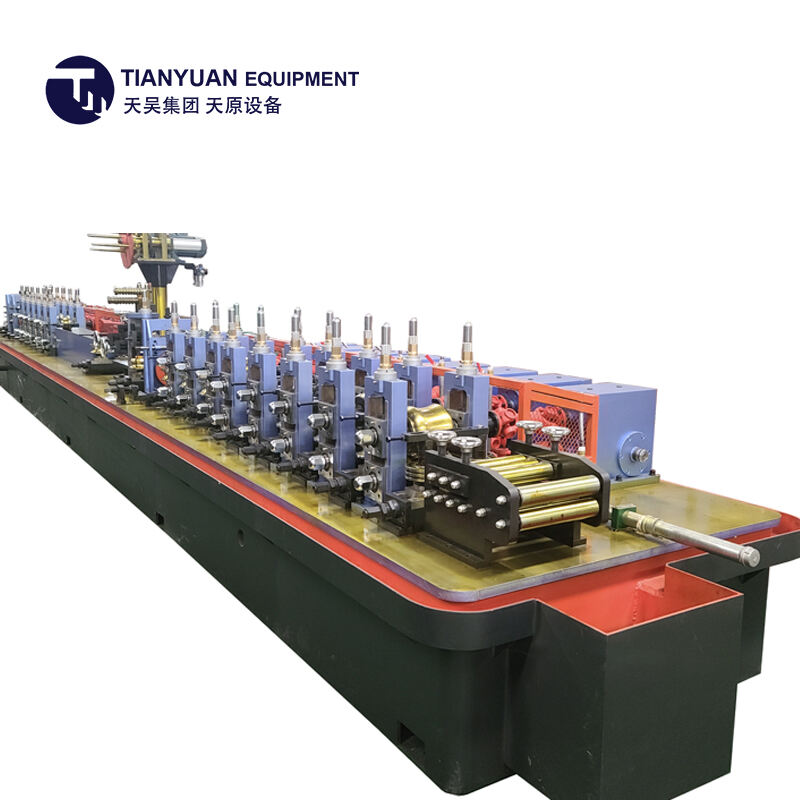

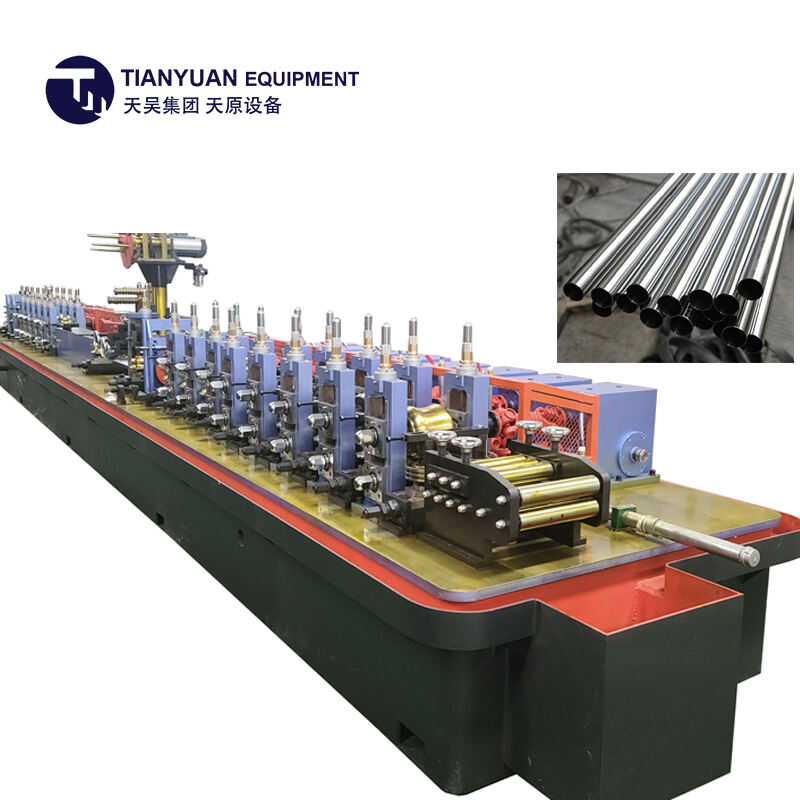

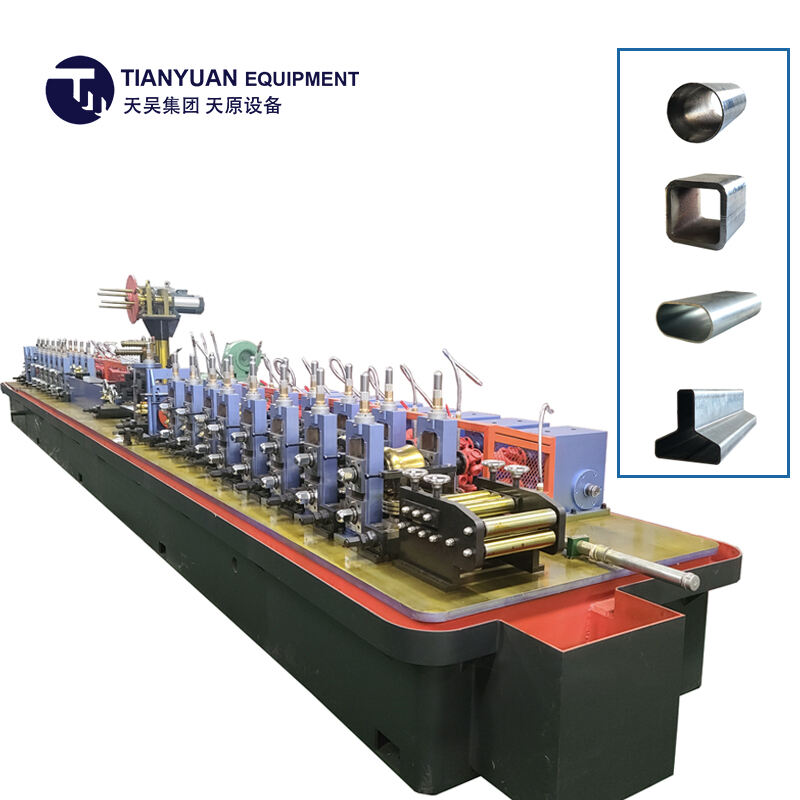

high quality carbon steel pipe making machine

The high quality carbon steel pipe making machine represents a pinnacle of modern manufacturing technology, designed to produce precise and durable steel pipes for various industrial applications. This sophisticated equipment combines advanced automation with precision engineering to transform raw carbon steel into high-quality pipes through a systematic process. The machine features state-of-the-art forming technology that ensures consistent pipe diameter and wall thickness, while its intelligent control system maintains optimal production parameters throughout the manufacturing cycle. The production line typically includes multiple stages: material feeding, forming, welding, sizing, straightening, and cutting. Each stage is equipped with sensors and quality control mechanisms that monitor and adjust the process in real-time. The machine's versatile design allows for the production of pipes ranging from small diameters to large industrial sizes, with the capability to handle various wall thicknesses. Its robust construction ensures reliable operation under continuous production conditions, while the advanced welding system creates strong, uniform seams that meet international quality standards. The machine also incorporates energy-efficient components and waste reduction features, making it environmentally responsible while maintaining high productivity levels.