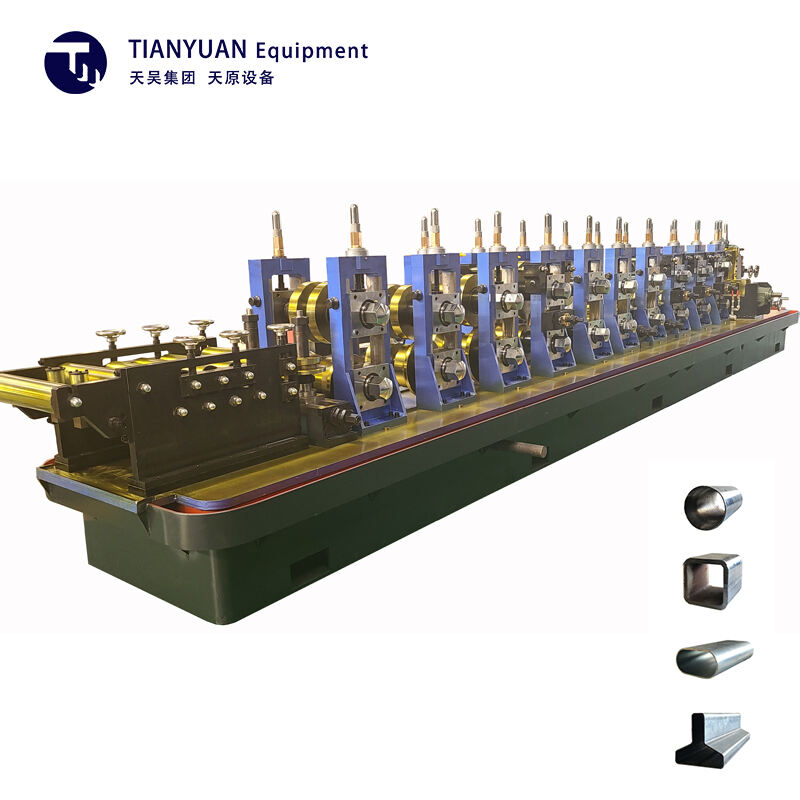

low cost gi pipe making machine

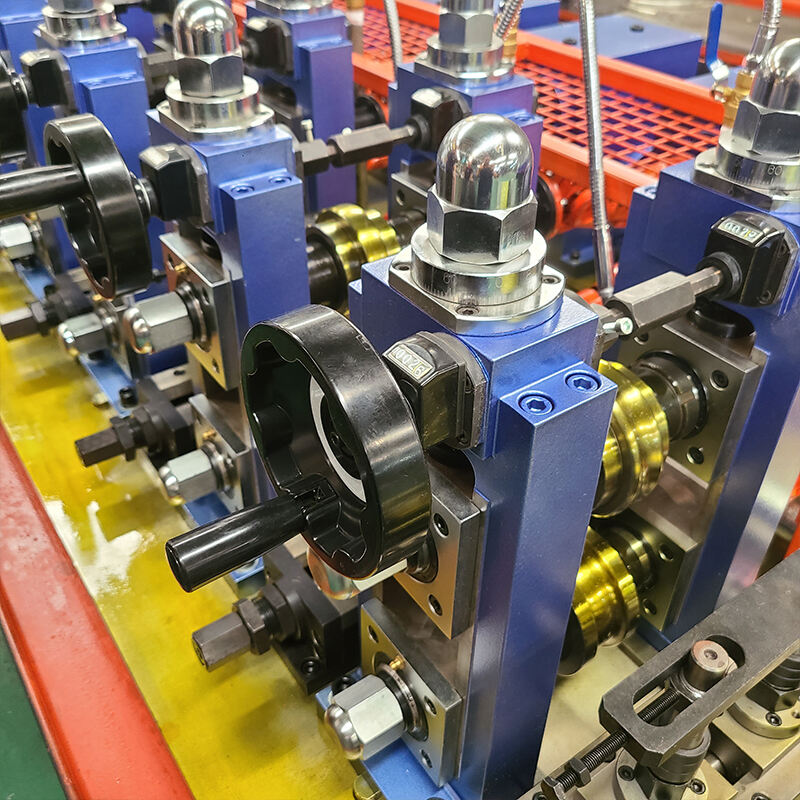

The low cost GI pipe making machine represents a significant advancement in pipe manufacturing technology, offering an economical solution for producing high-quality galvanized iron pipes. This versatile equipment operates through a systematic process that begins with raw material feeding and concludes with precise pipe formation. The machine incorporates advanced roll forming technology, enabling continuous production of pipes with diameters ranging from 15mm to 100mm. Its automated control system ensures consistent quality while maintaining efficient production speeds of up to 30 meters per minute. The machine features precision cutting mechanisms, integrated welding stations, and sophisticated cooling systems that work in harmony to produce pipes meeting international standards. The equipment's modular design allows for easy maintenance and quick size changeovers, maximizing operational efficiency. Safety features include emergency stop systems, protective guards, and automated fault detection mechanisms. The machine's compact footprint makes it suitable for both small and medium-sized manufacturing facilities, while its energy-efficient motors help reduce operational costs. Additionally, the machine's robust construction ensures longevity and reliable performance in demanding industrial environments.