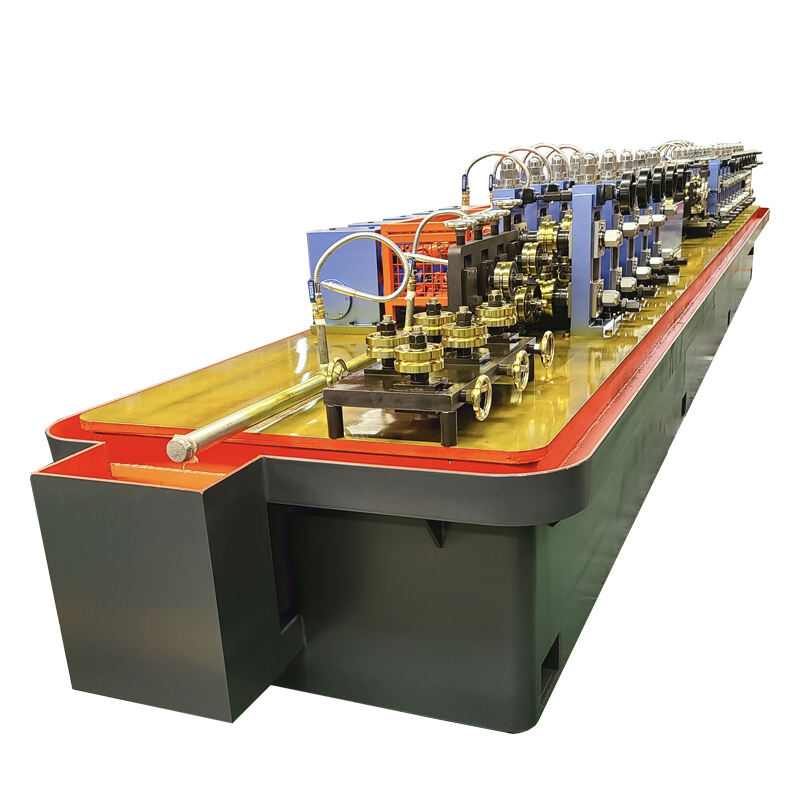

uzun ömürlü ms tüb hazırlama maşını

Daimi işləyən MS lüle hazırlama maşını, metal lüle üzmə prosesində inkişaf etmiş bir həllini təmsil edir və yumşaq çərəz lüllərinin istisna qabaqcıl performans və güvəncəli şəkildə hazırlanmasını təmin etmək üçün dizayn edilib. Bu mürəkkəb texnikada əvvəzləşdirici texnologiyalar və qalın inşaati birləşdirilmişdir ki, bu da sadəcə yüksək keyfiyyətli nəticələri təmin edir. Maşın, açarlıq, səviyyələndirmə, formalaşdırma, lövhələmə, ölçülər və kəsmə proseslərini özündə birləşdirən tamamilə inteqrallanmış bir hasilat xəttinə malikdir. Dəqiqliklə formalaşdırılmış stasiyonlar düz çərəz şeritlərini dairəvi lüllərə dəyişdirir, bu isə yüksək-təqrirli lövhələmə sistemi ilə güclü və bərabər sətləri təmin edir. Maşının avtomatlaşdırılmış imkanları lüle ölçülərində sürətli dəyişikliklərə imkan verir ki, bu da onu 20mm-dən 76mm diyarda olan müxtəlif spesifikasiyalara uyğun olaraq çoxsaylı olaraq idarə etməyə yarayır. İnteqrallanmış keyfiyyət idarəetmə sistemləri, materialların təchizatından son kəsməyə qədər hasilatın hər hissəsini izləyir və hər lülinin ciddi sənaye standartlarına uyğun olduğunu təmin edir. Dakika başı 40 metr sürətdə işləyən bu maşın istisna qabaqcıl dəqiqlik saxlayarkən impression verən hasilat dərəcələrini təmin edir. Qalın çərəz komponentlərlə və dəqiqlik balları ilə inşa edilmiş rəqəmsiz inşaat minimal texniki təmir tələblərini və uzun işləmə ömrünü təmin edir. Bu maşın əsasən tikinti, möbilya hazırlama, avtomobil komponentləri və müxtəlif sənaye tətbiqləri üçün lüllər hazırlamaq üçün uyğundur.