Core Technologies Driving Efficiency in Steel Pipe Making Machines

High-Speed Material Handling and Waste Reduction Techniques

Good material handling systems really matter when it comes to keeping production moving fast and cutting down on wasted materials in steel pipe manufacturing. These systems make sure raw materials get where they need to go quickly and finished products move out just as fast, which keeps everything running smoothly day after day. When companies focus on reducing waste through approaches like lean manufacturing practices and finding ways to reuse scrap metal, they see real benefits both financially and environmentally. According to EPA reports, factories that implement these strategies often save around 20-25% on costs while also slashing their carbon emissions considerably. For steel pipe makers looking to stay competitive, investing in better material management isn't just about saving money anymore—it's becoming a necessity for long term business survival in today's market.

Advanced Welding and Forming Mechanisms for Seamless Output

Advanced welding methods like laser and TIG techniques keep steel pipes strong and structurally sound, which makes them perfect for everything from oil pipelines to construction projects. The way seamless pipes are formed actually boosts their overall quality, giving them extra strength when put under pressure in real world conditions. Looking ahead, many in the field see exciting changes coming with new approaches such as hybrid laser-arc welding technology. A recent report from the Welding Journal suggests these kinds of improvements could lead to better quality products while cutting down on manufacturing expenses across the board. For pipe makers trying to stay competitive, these technological leaps mean they can produce higher quality goods faster than ever before, meeting customer needs without breaking the bank on production costs.

Types of Steel Pipe Making Machines and Their Efficiency Applications

Induction Machines for Large-Diameter Industrial Demands

Induction machines play a vital role in making those big diameter pipes needed across various heavy industries. Built to handle substantial workloads, these machines last longer and perform reliably under tough conditions that most factories demand. People who know the industry talk about how induction machines really shine when it comes to producing consistent results without breakdowns, something absolutely necessary for major construction projects involving pipelines or city infrastructure developments. Their ability to maintain steady production rates makes them indispensable in settings where downtime simply isn't an option.

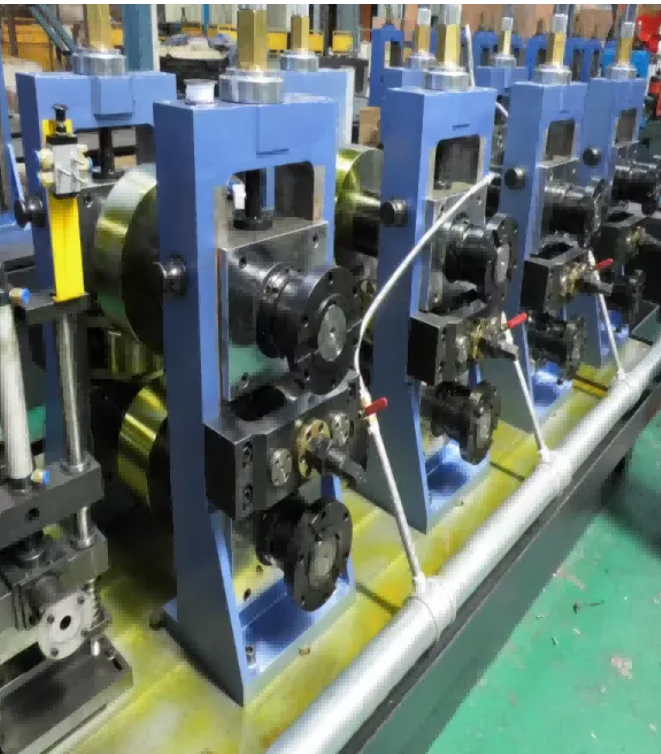

Cold Roll Forming Mills for Precision Small-Diameter Tubes

Cold roll forming mills have become essential equipment in precision manufacturing operations, particularly when working with small diameter tubes. The machines deliver tight tolerances that manufacturers need, plus they consume less energy compared to traditional methods, which means better quality products come off the line every time. We're seeing increased demand for these tiny tubes throughout different industries right now. Market research shows this trend is accelerating as companies in automotive manufacturing, aerospace engineering, and electronic component production all find new ways to incorporate them into their product designs.

By exploring these types of machines, we can better understand their efficiency applications across diverse industrial needs, especially in maximizing productivity without compromising quality standards.

Maintenance Strategies for Sustained Productivity

Preventive Care for Critical Components (Motors, Bearings, Hydraulics)

Keeping steel pipe making machines productive over time means staying ahead of maintenance needs, especially when it comes to those vital parts like motors, bearings, and hydraulic systems. Regular maintenance doesn't just prolong component life, it also cuts down on surprise breakdowns that stop production cold. When manufacturers stick to inspection schedules and don't skip routine checks, they see far less downtime and their operations run smoother overall. Research from plant managers across North America indicates that proper maintenance reduces machine failures by around 40%, which adds up to real money saved on repairs and lost production time. Most plants report getting at least 20% better uptime simply by following basic maintenance protocols religiously, something that makes all the difference in meeting production targets month after month.

Optimizing Electrical Systems and Power Consistency

Good electrical system management makes all the difference when it comes to getting the most out of steel pipe manufacturing equipment. Keeping power supply stable matters a lot because voltage drops or surges really mess with machine efficiency and often cause unexpected shutdowns. Practical approaches include installing variable frequency drives along with smart load balancing across different production stages. Real world testing shows factories that upgrade their electrical infrastructure typically see around 15-20% gains in output per shift. When energy gets used properly, the whole production line runs smoother without those frustrating stoppages. These kinds of improvements boost daily throughput while cutting down on electricity bills month after month, which adds up nicely over time for plant managers watching bottom lines.

Innovations Redefining Manufacturing Standards

Digital Monitoring Systems for Real-Time Quality Control

Manufacturing quality control is getting a major boost from digital monitoring systems that offer instant data insights and help streamline processes. These advanced tools let manufacturers spot problems fast before they turn into costly issues, which cuts down on wasted materials and keeps products consistent across batches. Some recent research points to how these monitoring technologies actually cut down on factory errors, making whole operations run smoother. When factories plug in these analytical capabilities, they not only tweak their production lines for better results but also stick to tighter quality specs. Plus, when something goes off track during manufacturing, teams catch it quicker and fix whatever's wrong, so end products meet expectations and money isn't thrown away on defective goods.

Sustainable Practices in Steel Recycling and Energy Use

The manufacturing sector is increasingly turning its attention to sustainability, particularly within steel pipe production. Recycling steel on a large scale has become one of the main ways manufacturers cut down their environmental footprint while also saving money on operations. Energy efficiency is another area where companies are making real progress. Many plants now run partially on solar or wind power, and improvements in how energy is used throughout production processes have made a noticeable difference. We're seeing an actual trend toward greener operations across the industry. Companies that adopt these practices tend to stand out from competitors because they meet regulatory requirements and appeal to customers who care about environmental responsibility. This shift shows what kind of manufacturer someone really wants to do business with.

FAQ Section

What is the role of automation in steel pipe making machines?

Automation enhances efficiency by integrating technologies such as PLCs and CNC systems, reducing human error, and optimizing material use.

How do material handling systems contribute to operational efficiency?

Material handling systems support high production speed and waste reduction, crucial for efficient steel pipe manufacturing processes.

Why are induction machines important for large-diameter pipes?

Induction machines are vital for ensuring durability and meeting industrial demands, especially in heavy industries requiring large-diameter pipes.

What maintenance strategies help sustain productivity in steel pipe making machines?

Implementing preventive maintenance and optimizing electrical systems are key strategies for maintaining sustained productivity and reducing breakdowns.

How are sustainable practices beneficial in steel pipe production?

Sustainable practices reduce environmental impact and operational costs, giving companies a competitive edge and fulfilling consumer expectations.

Table of Contents

- Core Technologies Driving Efficiency in Steel Pipe Making Machines

- Types of Steel Pipe Making Machines and Their Efficiency Applications

- Maintenance Strategies for Sustained Productivity

- Innovations Redefining Manufacturing Standards

-

FAQ Section

- What is the role of automation in steel pipe making machines?

- How do material handling systems contribute to operational efficiency?

- Why are induction machines important for large-diameter pipes?

- What maintenance strategies help sustain productivity in steel pipe making machines?

- How are sustainable practices beneficial in steel pipe production?