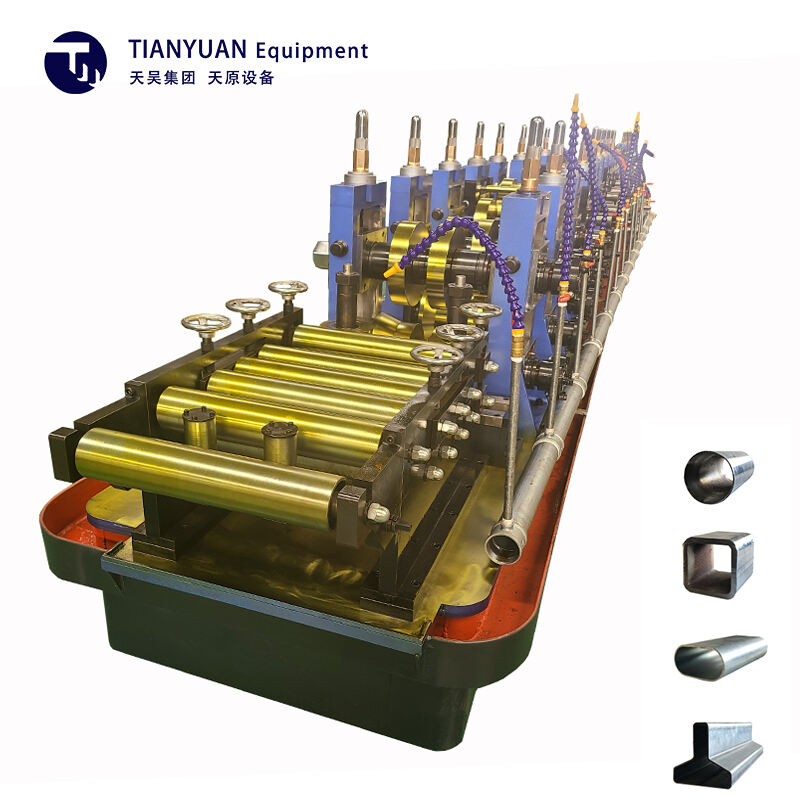

নিম্ন মূল্যের জি আই পাইপ তৈরির মেশিন

নিম্ন মূল্যের জিআই পাইপ তৈরি মशিন উচ্চ-গুণবত্তা সহ গ্যালভানাইজড আয়রন পাইপ তৈরির জন্য একটি ব্যয়-কার্যকর সমাধান প্রতিনিধিত্ব করে। এই বহুমুখী সরঞ্জাম উন্নত প্রযুক্তি এবং ব্যবহারিক ফাংশনালিটি একত্রিত করে, বিভিন্ন পাইপ বিশেষত্বের জন্য একটি সরলীকৃত উৎপাদন প্রক্রিয়া প্রদান করে। মেশিনের মধ্যে একটি দৃঢ় ডিজাইন রয়েছে যা একটি ধীরে ধীরে ধাতব ব্যান্ডকে পূর্ণতः গোলাকার পাইপে আকৃতি দেয়। এর নির্ভুল নিয়ন্ত্রণ পদ্ধতি নির্দিষ্ট পাইপ ব্যাস এবং দেওয়াল মোটা রাখতে সমর্থ হয়, যখন একত্রিত ওয়েল্ডিং ইউনিট শক্তিশালী এবং টিকে থাকা সিল তৈরি করে। মেশিন বিভিন্ন ম্যাটেরিয়াল মোটা অনুমোদন করে এবং ১৫মিমি থেকে ১০০মিমি ব্যাসের পাইপ উৎপাদন করতে সক্ষম। অটোমেটেড ফিডিং সিস্টেম স্থিতিশীল ম্যাটেরিয়াল ফ্লো রক্ষা করে, যখন ছেদন মেকানিজম নির্ভুল দৈর্ঘ্য নিয়ন্ত্রণ প্রদান করে। আধুনিক পিএলসি নিয়ন্ত্রণ দ্বারা বাড়ানো হয়েছে, মেশিন সহজ চালনা এবং ন্যূনতম রক্ষণাবেক্ষণের প্রয়োজন প্রদান করে। নিরাপত্তা বৈশিষ্ট্যগুলি অতিরিক্ত জরুরী বন্ধ বোতাম এবং গতিশীল অংশের চারপাশে সুরক্ষিত গার্ড অন্তর্ভুক্ত করে। মেশিনের দক্ষ ডিজাইন ম্যাটেরিয়াল ব্যয় এবং শক্তি ব্যয় হ্রাস করে, যা নিম্ন চালনা ব্যয়ের অবদান রাখে। এর সংক্ষিপ্ত পদচিহ্ন বিভিন্ন কার্গো ব্যবস্থায় উপযুক্ত করে, যখন এর দীর্ঘ সময় ধরে নির্ভরযোগ্যতা নিশ্চিত করে। এই সিস্টেমে প্রয়োজনীয় উপাদান যেমন ডিকয়োলিং ইউনিট, আকৃতি দেওয়ার স্টেশন, ওয়েল্ডিং সিস্টেম এবং ফিনিশিং সেকশন সবই একত্রে কাজ করে যে উচ্চ-গুণবত্তা জি আই পাইপ তৈরি করে যা বিভিন্ন শিল্পীয় এবং বাণিজ্যিক ব্যবহারের জন্য উপযুক্ত।