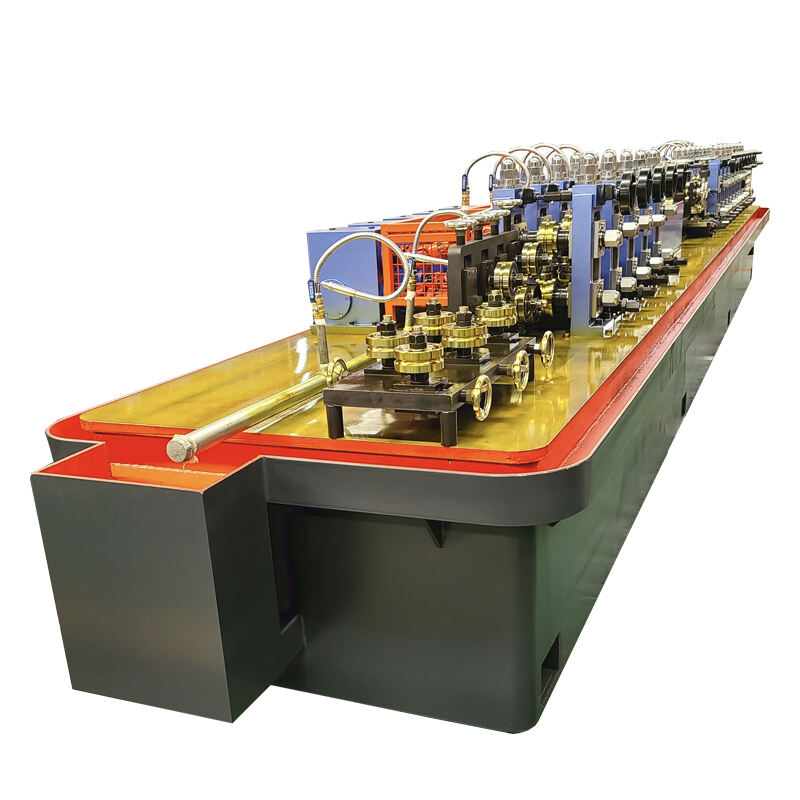

সমাধান জি-আই পাইপ তৈরি মেশিন

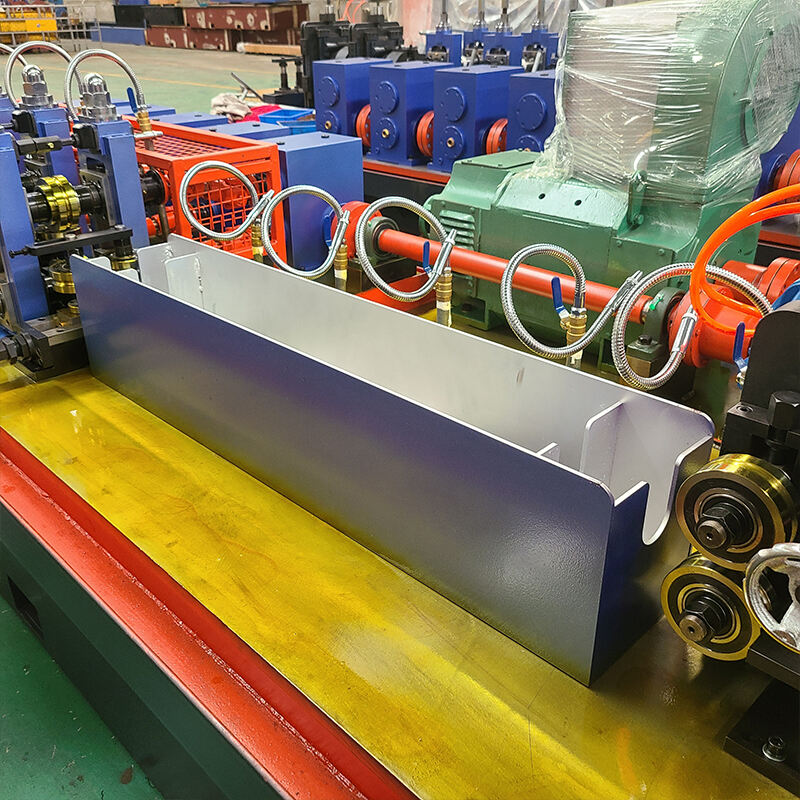

সমাধান GI পাইপ তৈরি মেশিন হল একটি সর্বনবতম উৎপাদন পদ্ধতি, যা গলনযোগ্য লোহা পাইপ তৈরি করতে নির্ভুলতা এবং দক্ষতা সহ ডিজাইন করা হয়েছে। এই উন্নত যন্ত্রটি বহুমুখী প্রক্রিয়া একত্রিত করেছে, যার মধ্যে ডিকয়োলিং, আকৃতি দেওয়া, সোজা করা, আকার নির্দিষ্ট করা এবং গ্যালভানাইজিং অন্তর্ভুক্ত রয়েছে, সবই একটি অবিচ্ছিন্ন উৎপাদন লাইনে। যন্ত্রটি উচ্চ-ফ্রিকোয়েন্সি সোজা করা প্রযুক্তি ব্যবহার করে শক্ত, একক সেল নিশ্চিত করে এবং সঙ্গত পাইপ আকার বজায় রাখে। এর স্বয়ংক্রিয় নিয়ন্ত্রণ পদ্ধতি স্পর্শ-স্ক্রিন ইন্টারফেস এবং PLC প্রোগ্রামিং বৈশিষ্ট্য বহন করে, যা অপারেটরদেরকে উৎপাদন পরামিতি বাস্তব-সময়ে পরিদর্শন এবং সামঞ্জস্য করতে দেয়। যন্ত্রটি বিভিন্ন পাইপ বিন্যাস প্রক্রিয়া করতে পারে, সাধারণত ১/২ ইঞ্চি থেকে ৪ ইঞ্চি ব্যাসের পাইপ উৎপাদন করে, দেওয়াল বেধা ১.৫mm থেকে ৪mm। উৎপাদন লাইনটি উন্নত গ্যালভানাইজিং প্রযুক্তি ব্যবহার করে যা সমতল জিন্স কোটিং প্রয়োগ নিশ্চিত করে, উত্তম ক্ষয় প্রতিরোধ প্রদান করে। পদ্ধতির গুণবত্তা নিয়ন্ত্রণ মেকানিজম, যা অতিধ্বনি পরীক্ষা এবং আকার যাচাই অন্তর্ভুক্ত রয়েছে, নিশ্চিত করে যে প্রতিটি পাইপ শিল্পীয় মান পূরণ করে। ৫০ মিটার প্রতি মিনিট পর্যন্ত উৎপাদন গতি উৎপাদন দক্ষতা বৃদ্ধি করে এবং পণ্যের গুণবত্তা বজায় রাখে।