Porozumění moderní technologii výroby trubek ERW

The ERW Pipe Mill představuje základ moderní průmyslové výroby trubek, která revolucí změnila způsob výroby vysoce kvalitních svařovaných trubek. Tento sofistikovaný výrobní systém kombinuje přesné inženýrství s pokročilou technologií svařování, aby vytvářel trubky splňující přísné průmyslové normy. Prostřednictvím odporového svařování (ERW) tyto linky přeměňují ploché ocelové pásky na pevné, rovnoměrné trubky, které jsou nezbytné pro různé aplikace ve více odvětvích.

Dnešní zařízení válcovny trubek ERW představují vrchol desetiletí technologického pokroku ve výrobě trubek. Tyto moderní instalace zahrnují automatické řídicí systémy, přesné monitorovací systémy a inovativní svařovací techniky, které zajišťují stálou kvalitu výrobků. Význam válcoven trubek ERW ve moderní výrobě nelze podceňovat, protože poskytují efektivní a nákladově výhodné řešení pro výrobu trubek sloužících kritickým infrastrukturním potřebám po celém světě.

Hlavní komponenty a operační principy

Základní vybavení ve válcovně trubek ERW

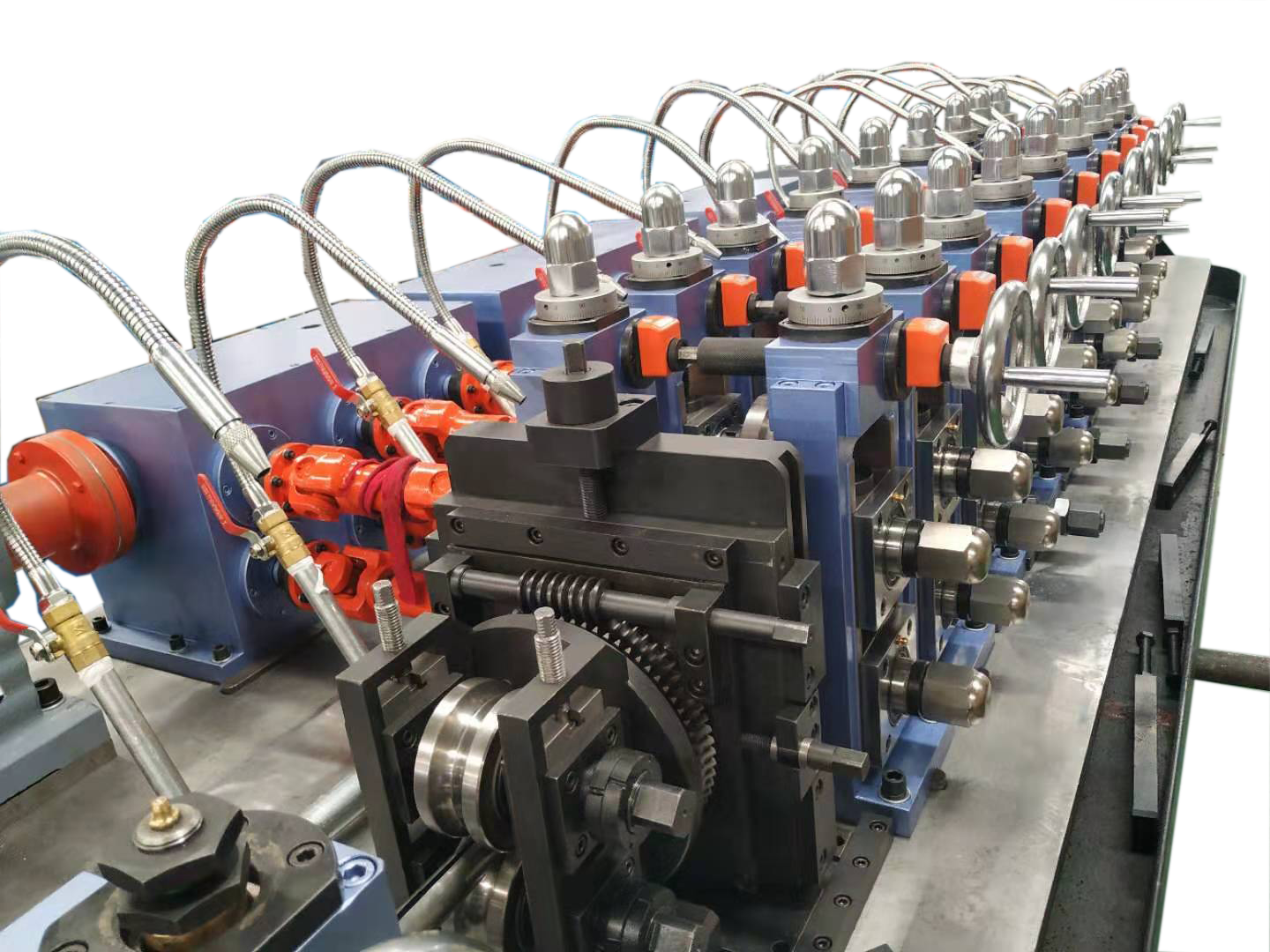

V srdci každého válcovacího útvaru pro ERW trubky se nachází řada specializovaných strojů navržených tak, aby z ploché oceli vyráběly válcové potrubí. Proces začíná s odvíječem, který podává ocelové pásky do válcovny. Tvárnicí válce postupně tvarují ocel do trubkovité podoby, zatímco zařízení pro vysokofrekvenční svařování bezševně spojuje okraje. Staničení kontroly kvality, včetně ultrazvukového zkušebního zařízení a kalibrovacích jednotek, zajistí, že konečný výrobek splňuje přesné specifikace.

Útvar rovněž obsahuje sofistikované řezací systémy, manipulační zařízení a automatická balicí řešení. Každá součást hraje klíčovou roli při udržování efektivity výroby a kvality výrobků. Moderní válcovny pro ERW trubky často disponují pokročilými automatickými systémy, které tyto různé komponenty koordinují, optimalizují tok výroby a minimalizují prostoji.

Tok výrobního procesu

Výrobní proces na ohýbacím zařízení pro ERW trubky probíhá podle přesně koordinovaného postupu. Zpočátku jsou ocelové cívky naloženy na odvíječ, kde jsou opatrně vedeny do zařízení. Pás poté prochází více stadia tváření, z nichž každé je přesně kalibrováno tak, aby dosáhlo požadovaného průměru a tvaru trubky. Kritická fáze svařování nastává, když se okraje spojí, přičemž se používá vysoce frekvenčního odporového svařování elektrickým proudem, které vytváří pevný a rovnoměrný šev.

Po svařování trubka podléhá okamžitému tepelnému zpracování za účelem odstranění pnutí v oblasti svaru. Následující fáze zahrnují chlazení, kalibrování a narovnávání. Kontrola kvality je integrována po celém procesu, přičemž jak automatické, tak ruční kontroly zajišťují, že každá trubka splňuje požadované specifikace. Poslední kroky zahrnují řezání na délku, dokončování konců a přípravu ke spedičnímu odeslání.

Kontrola kvality a výrobní standardy

Technologie inspekce

Moderní zařízení pro výrobu ERW trubek využívají sofistikované kontrolní systémy, které zajišťují přísné normy kvality. Metody nedestruktivního testování, včetně ultrazvukového a vířivého proudu, neustále monitorují kvalitu svarů. Pokročilé systémy strojového vidění vyhledávají povrchové vady, zatímco laserové měřicí přístroje zajišťují přesnost rozměrů. Tyto technologie spolupracují tak, aby identifikovaly a řešily potenciální problémy dříve, než ovlivní konečný produkt.

Laboratoře kontroly kvality umístěné ve výrobním zařízení provádějí pravidelné testování materiálu, analyzují mechanické vlastnosti, chemické složení a pevnost svarů. Tento komplexní přístup k zajištění kvality zajišťuje, že vyráběné trubky splňují nebo převyšují průmyslové normy i požadavky zákazníků.

Certifikace a shody

Výrobní linky pro ERW trubky musí dodržovat přísné mezinárodní normy a certifikační požadavky. Patří sem soulad s normami API, ASTM a ISO a dalšími. Pravidelné audity a certifikace zajišťují, že výrobní procesy a systémy kontroly kvality udržují nejvyšší standardy excelence. Dokumentační a systémy stopovatelnosti sledují výrobní historii každé trubky od suroviny až po hotový výrobek.

Také environmentální a bezpečnostní certifikace hrají klíčovou roli v moderních provozech linek. Zařízení musí prokázat soulad s environmentálními předpisy a zároveň zajišťovat bezpečné pracovní podmínky pro personál. Tento závazek dodržováním norem sahá dál než pouze kvalita výroby a zahrnuje všechny aspekty provozu linky.

Aplikace a poptávka na trhu

Průmyslové použití a technické specifikace

ERW trubky vyráběné v těchto závodech slouží pro různé průmyslové aplikace. Odvětví těžby ropy a zemního plynu silně závisí na těchto trubkách pro přepravní a distribuční sítě. Stavebnictví je využívá pro konstrukční účely a technické služby. Systémy pro přepravu vody, chemické procesní zařízení a výrobní provozy všechny spoléhají na ERW trubky pro svůj chod.

Různé aplikace vyžadují specifické parametry trubek, včetně různých průměrů, tlouštěk stěn a tříd oceli. Závody na výrobu ERW trubek musí zachovat flexibilitu výroby trubek splňujících tyto rozmanité požadavky, a zároveň zajistit konzistentní kvalitu všech výrobků.

Trhy a budoucnost

Celosvětová poptávka po trubkách ERW dále roste, a to díky rozvoji infrastruktury a průmyslové expanzi. Zejména silná poptávka se objevuje na rozvíjejících se trzích, kde rostou investice do infrastruktury pro ropu a plyn, systémů pro hospodaření s vodou a stavebních projektů. Tento růst vytváří příležitosti pro výrobny trubek ERW rozšířit své možnosti a zlepšit efektivitu výroby.

Technologické pokroky ve výrobě válcoven a procesech se dále vyvíjejí a slibují ještě vyšší přesnost a produktivitu. Trendy v odvětví směřují k vyšší automatizaci, lepší energetické účinnosti a vylepšeným systémům kontroly kvality, čímž zajišťují, že výrobny trubek ERW zůstanou na špici průmyslové výrobní technologie.

Nejčastější dotazy

Čím se výroba trubek ERW liší od jiných metod výroby trubek?

Výroba trubek ERW se odlišuje použitím technologie elektrického odporového svařování, která vytváří nepřetržitý a vysoce pevný svar. Tento proces nabízí výhody v rychlosti výroby, nákladové efektivitě a konzistenci ve srovnání s jinými metodami, jako je výroba bezešvých trubek nebo spirálové svařování.

Jak zajišťují továrny na trubky ERW konzistentní kvalitu produktu?

Továrny na trubky ERW udržují kvalitu prostřednictvím vícevrstvé kontroly, včetně automatických kontrolních systémů, nepřetržitého monitorování svařovacích parametrů a komplexních testovacích protokolů. Pravidelná kalibrace zařízení, školení obsluhy a přísné dodržování mezinárodních norem přispívají ke konzistentní kvalitě produktu.

Jaké jsou hlavní požadavky na údržbu továrny na trubky ERW?

Údržba zařízení pro výrobu ERW trubek vyžaduje pravidelnou kontrolu a servis kritických komponent, zejména tvakovacích válců, svařovacího zařízení a zkušebních systémů. Preventivní plány údržby, pečlivé sledování opotřebitelných částí a periodická kalibrace řídicích systémů přispívají k zajištění optimálního výkonu a minimalizaci výpadků.