Die Fertigungsindustrie verlangt heute nach Ausrüstungen, die sowohl Präzision als auch Anpassungsfähigkeit bei unterschiedlichsten Produktionsanforderungen bieten. Eine Rohrformmaschine stellt eine der vielseitigsten Lösungen zur Herstellung von Rohrkomponenten in zahlreichen Branchen dar – von Bauwesen und Automobilindustrie bis hin zur Luft- und Raumfahrt sowie Energieinfrastruktur. Diese hochentwickelten Systeme wandeln flache Metallbänder durch kontrollierte Formprozesse in exakt dimensionierte Rohre um, wobei die Materialintegrität erhalten bleibt und gleichzeitig konsistente Qualitätsstandards erreicht werden. Moderne Rohrformtechnologien haben sich dahingehend weiterentwickelt, dass sie verschiedene Materialien, Wandstärken und Durchmesseranforderungen bewältigen können, wodurch sie zu einem unverzichtbaren Bestandteil für Hersteller werden, die operative Flexibilität und hohe Produktionseffizienz anstreben.

Grundlagen der Rohrformtechnologie verstehen

Kernformprozesse und -mechanismen

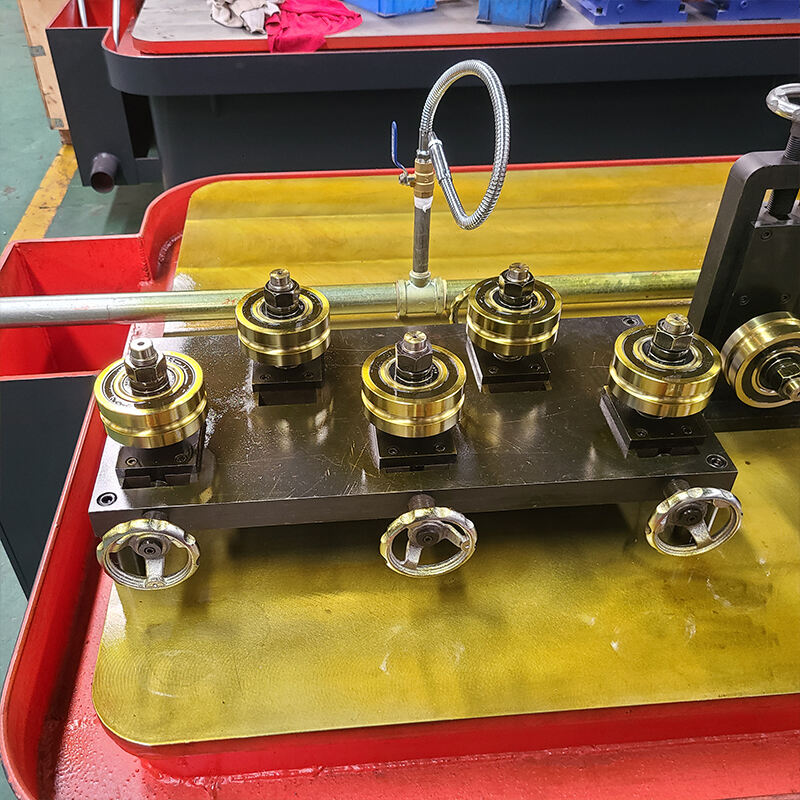

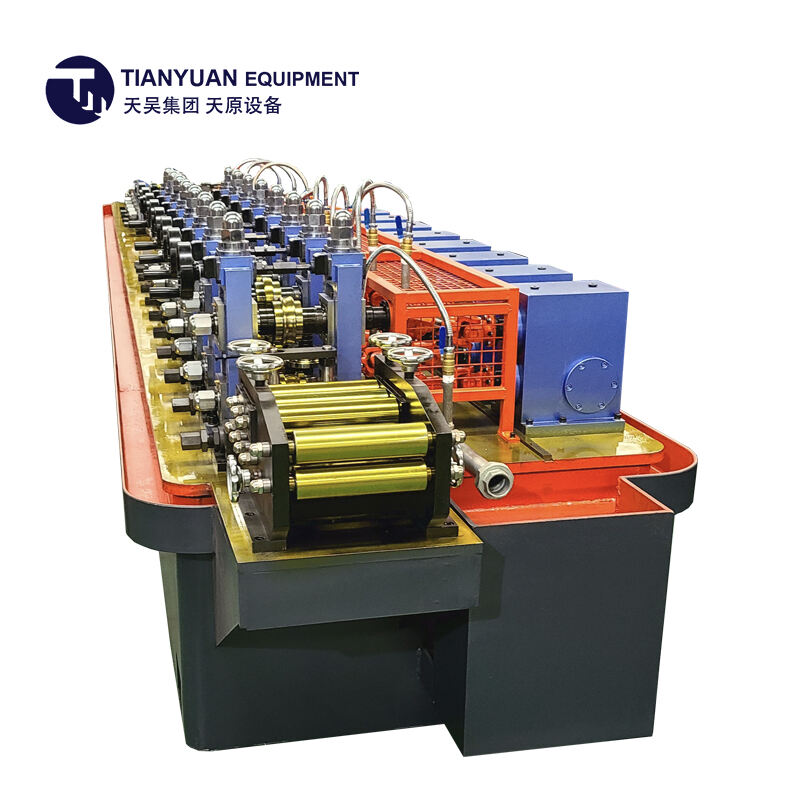

Die grundlegende Funktionsweise einer Rohrformmaschine umfasst die schrittweise Formgebung von Metallbändern durch strategisch positionierte Formrollen. Diese Maschinen nutzen präzisen mechanischen Druck, um das Material allmählich zu zylindrischen Formen zu biegen, ohne die strukturelle Integrität zu beeinträchtigen. Der Prozess beginnt mit der Materialvorbereitung, bei der Metallcoils oder -bleche durch Ausrichtsysteme geführt werden, die eine konsistente Positionierung während der gesamten Formsequenz sicherstellen. Fortschrittliche Steuerungssysteme überwachen Materialspannung, Formgeschwindigkeit und Druckverteilung, um optimale Bedingungen für jede spezifische Anwendung aufrechtzuerhalten.

Die Temperaturregelung spielt eine entscheidende Rolle beim Umformprozess, insbesondere bei Materialien, die bestimmte thermische Bedingungen für optimale Verformbarkeit erfordern. Moderne Rohrformmaschinen verfügen über hochentwickelte Heizelemente und Kühlsysteme, die je nach Materialzusammensetzung und gewünschten End eigenschaften angepasst werden können. Diese Fähigkeit zum thermischen Management ermöglicht es Herstellern, mit einer breiteren Palette von Materialien zu arbeiten, während gleichzeitig konstante Qualitätsstandards über alle Produktionsdurchläufe hinweg gewahrt bleiben.

Materialverträglichkeit und Verarbeitungsbereich

Moderne Rohrformmaschinen zeichnen sich durch eine bemerkenswerte Vielseitigkeit bei der Verarbeitung verschiedener Metallarten aus, darunter Kohlenstoffstahl, Edelstahl, Aluminium und Speziallegierungen. Jedes Material weist einzigartige Umformeigenschaften auf, die spezifische Maschinenanpassungen erfordern, um optimale Ergebnisse zu erzielen. Kohlenstoffstahl, einer der am häufigsten verarbeiteten Werkstoffe, bietet hervorragende Umformbarkeit und Festigkeitseigenschaften, wodurch er sich ideal für strukturelle Anwendungen eignet. Die Fähigkeit der Maschine, unterschiedliche Materialstärken zu verarbeiten – typischerweise von dünnwandigen Blechen bis hin zu dickwandigen Anwendungen – erweitert ihre Einsatzmöglichkeiten erheblich über verschiedene Industriebereiche hinweg.

Der Bearbeitungsbereich erstreckt sich über die Materialvielfalt hinaus und umfasst auch dimensionsbedingte Flexibilität, wobei moderne Systeme in der Lage sind, Rohre von kleinen Durchmessern für Präzisionsanwendungen bis hin zu großdimensionierten Rohren für Infrastrukturprojekte herzustellen. Diese dimensionsbezogene Vielseitigkeit macht den Einsatz mehrerer spezialisierter Maschinen überflüssig, reduziert die erforderlichen Kapitalinvestitionen und maximiert gleichzeitig die Effizienz der Produktionsfläche. Fortschrittliche programmierbare Steuerungen ermöglichen es den Bedienern, schnell zwischen verschiedenen Spezifikationen zu wechseln, wodurch die Rüstzeiten minimiert und die produktive Kapazität maximiert wird.

Produktionsvielfalt und betriebliche Vorteile

Mehrfach-Durchmesser-Fähigkeit und schnelle Umrüstung

Einer der bedeutendsten Vorteile moderner Rohrformmaschinen ist ihre Fähigkeit, mehrere Rohrdurchmesser ohne umfangreiche Umrüstung herzustellen. Fortschrittliche Walzformanlagen nutzen verstellbare Formstationen, die zur Anpassung an verschiedene Rohrspezifikationen mittels automatisierter oder halbautomatisierter Justiermechanismen neu positioniert werden können. Diese Funktion reduziert die Rüstzeiten zwischen Produktionsläufen erheblich und ermöglicht es Herstellern, schnell auf wechselnde Marktanforderungen oder Kundenanforderungen zu reagieren, ohne nennenswerte Produktionsverzögerungen in Kauf nehmen zu müssen.

Die schnelle Umrüstfunktion erstreckt sich auch auf Wanddickevariationen, wodurch es den Bedienern ermöglicht wird, unterschiedliche Materialstärken innerhalb einer Produktionsschicht zu verarbeiten. Programmierbare Steuerungssysteme speichern die Einrichtparameter für häufig hergestellte Spezifikationen und ermöglichen Konfigurationsänderungen per Knopfdruck, wodurch der Bedieneraufwand minimiert und das Risiko von Fehlern bei der Einrichtung verringert wird. Dieses Automatisierungsniveau trägt erheblich zur Gesamtauslastung der Anlage bei, während gleichzeitig konstante Qualitätsstandards über verschiedene Produktanforderungen hinweg gewahrt bleiben.

Integration in nachgeschaltete Verarbeitungsanlagen

Modern rohrformmaschine systeme sind mit Integrationsfunktionen ausgestattet, die eine nahtlose Verbindung mit nachgeschalteten Bearbeitungsanlagen wie Schweißstationen, Schneidanlagen und Qualitätsinspektionsgeräten ermöglichen. Diese Integrationsfähigkeit schafft komplette Produktionslinien, die Rohmaterialien in fertige Rohrprodukte mit minimalem manuellem Eingriff umwandeln können. Der synchronisierte Betrieb zwischen Form- und Nachbearbeitungsprozessen gewährleistet einen kontinuierlichen Materialfluss und gleichzeitig präzise zeitliche Abstimmungen, die für eine qualitativ hochwertige Produktion unerlässlich sind.

Die Integration erstreckt sich auf Datenerfassungs- und Prozessüberwachungssysteme, die Produktionskennzahlen, Qualitätsparameter und Leistungsindikatoren von Anlagen in Echtzeit verfolgen. Diese Vernetzung ermöglicht es Herstellern, umfassende Qualitätsmanagementsysteme zu implementieren, die eine vollständige Rückverfolgbarkeit von der Rohstoffeingabe bis zur Auslieferung des Endprodukts gewährleisten. Solche Funktionen sind besonders wertvoll in Branchen mit strengen Qualitätsanforderungen oder regulatorischen Compliance-Verpflichtungen.

Qualitätskontrolle und Präzisionsfertigung

Maßhaltigkeit und Konsistenz

Präzisionsfertigung erfordert eine gleichmäßige dimensionsgenaue Kontrolle während des gesamten Umformprozesses, und moderne Rohrformmaschinen zeichnen sich in diesem kritischen Bereich aus. Fortschrittliche Positionsrückmeldesysteme überwachen die Position der Formrollen mit mikrometergenauer Genauigkeit, wodurch sichergestellt wird, dass die Rohrabmessungen unabhängig von der Produktionsmenge oder dem Bedienerkönnen innerhalb der vorgegebenen Toleranzen bleiben. Regelkreissysteme gleichen automatisch Variationen in Materialeigenschaften, Umgebungsbedingungen oder Maschinenverschleiß aus, um eine gleichbleibende Ausgabegüte zu gewährleisten.

Die Konsistenz erstreckt sich über die Maßgenauigkeit hinaus auf die Oberflächenqualität, Rundheitstoleranzen und gleichmäßige Wanddicke. Hochentwickelte Überwachungssysteme erkennen Abweichungen von den festgelegten Parametern und leiten Korrekturmaßnahmen ein, bevor fehlerhafte Produkte entstehen. Dieser proaktive Qualitätsmanagementansatz minimiert Abfall und stellt sicher, dass alle hergestellten Rohre die Kundenanforderungen und Industriestandards erfüllen oder übertreffen.

Echtzeitüberwachung und Prozessoptimierung

Moderne Rohrformmaschinen verfügen über fortschrittliche Sensortechnologie, die Echtzeit-Rückmeldungen zu kritischen Prozessparametern wie Umformkraft, Materialposition und Maßhaltigkeit liefert. Diese kontinuierliche Überwachungsfähigkeit ermöglicht es den Bedienern, sofortige Anpassungen vorzunehmen, wenn Abweichungen erkannt werden, wodurch die Herstellung fehlerhafter Bauteile verhindert und Materialverschwendung minimiert wird. Die durch diese Überwachungssysteme gesammelten Daten liefern zudem wertvolle Erkenntnisse zur Prozessoptimierung und zur Planung vorausschauender Wartungsmaßnahmen.

Maschinelle Lernalgorithmen, die in moderne Steuerungssysteme integriert sind, analysieren historische Produktionsdaten, um Muster zu erkennen und Umformparameter automatisch zu optimieren. Diese intelligenten Systeme können optimale Einstellungen für neue Materialspezifikationen basierend auf ähnlichen früheren Produktionen vorhersagen, wodurch die Rüstzeit verkürzt und die Erstversuch-Ausschussquote verbessert wird. Die kontinuierliche Lernfähigkeit stellt sicher, dass sich die Maschinenleistung im Laufe der Zeit verbessert, da immer mehr Produktionsdaten für die Analyse zur Verfügung stehen.

Wirtschaftliche Vorteile und Rendite der Investition

Kosteneffizienz durch vielseitige Produktion

Die wirtschaftlichen Vorteile einer Investition in eine vielseitige Rohrformmaschine reichen weit über die anfänglichen Kapitalkosten hinaus. Die Fähigkeit, mehrere Rohrspezifikationen auf einer einzigen Maschine herzustellen, macht den Einsatz separater spezialisierter Geräte für unterschiedliche Produkte überflüssig und reduziert so erheblich den Kapitalbedarf. Diese Zusammenlegung verringert zudem den benötigten Platzbedarf, die Anschlüsse für Versorgungsleitungen sowie die Wartungskosten, die mit dem Betrieb mehrerer Maschinen für ähnliche Funktionen verbunden sind.

Die Arbeitseffizienz stellt einen weiteren bedeutenden wirtschaftlichen Vorteil dar, da Bediener mehrere Produkttypen mit vertrauter Ausrüstung und bekannten Steuerschnittstellen bedienen können. Die geringere Komplexität bei Schulungsanforderungen sowie die Eliminierung spezialisierter Bedienkenntnisse für unterschiedliche Maschinen tragen zu niedrigeren Betriebskosten und verbesserter Produktionseffizienz bei. Zudem ermöglicht die schnelle Umstellung zwischen Produkten eine Optimierung der Produktionsplanung basierend auf Nachfragemustern und Materialverfügbarkeit.

Marktreaktivität und Wettbewerbsvorteil

In der heutigen dynamischen Fertigungsumgebung bietet die Fähigkeit, schnell auf Marktveränderungen zu reagieren, erhebliche Wettbewerbsvorteile. Eine vielseitige Rohrbiegemaschine ermöglicht es Herstellern, Aufträge für verschiedene Rohrspezifikationen anzunehmen, ohne Bedenken hinsichtlich begrenzter Produktionskapazitäten haben zu müssen. Diese Flexibilität erlaubt es Unternehmen, unterschiedliche Marktmöglichkeiten zu nutzen und Beziehungen zu Kunden aufrechtzuerhalten, die zu verschiedenen Zeitpunkten unterschiedliche Produkttypen benötigen.

Die schnelle Rüstfähigkeit ermöglicht es Herstellern zudem, Just-in-Time-Produktionsstrategien umzusetzen, wodurch der Lagerbedarf minimiert wird, während gleichzeitig die Kundenservice-Level erhalten bleiben. Geringere Lagerkosten in Kombination mit der Fähigkeit, genau das zu produzieren, was benötigt wird, wenn es benötigt wird, tragen erheblich zu einer verbesserten Liquidität und reduzierten Umlaufvermögensanforderungen bei. Diese finanziellen Vorteile rechtfertigen die Investition in fortschrittliche Rohrbiegtechnologie oft innerhalb relativ kurzer Amortisationszeiten.

Künftige Trends und technologische Entwicklungen

Automatisierung und Industry 4.0 Integration

Die Weiterentwicklung der Rohrformmaschinentechnologie verläuft weiterhin in Richtung einer höheren Automatisierung und Integration nach den Prinzipien von Industrie 4.0. Fortschrittliche Robotersysteme werden zunehmend mit Formmaschinen kombiniert, um das Be- und Entladen von Material sowie Qualitätsinspektionen mit minimalem menschlichem Eingreifen durchzuführen. Diese automatisierten Systeme steigern nicht nur die Produktivität, sondern erhöhen auch die Sicherheit, indem sie die Belastung der Bediener gegenüber potenziellen Gefahren durch schweres Materialhandling und bewegte Maschinen verringern.

Künstliche Intelligenz und maschinelles Lernen erweitern ihre Funktionen um vorausschauende Wartungsfunktionen, die den Maschinenzustand überwachen und Komponentenausfälle vorhersagen, bevor sie eintreten. Diese prädiktiven Fähigkeiten minimieren ungeplante Ausfallzeiten und optimieren gleichzeitig die Wartungsplanung, um Kosten zu senken und die Verfügbarkeit der Ausrüstung zu verbessern. Die Integration dieser Technologien stellt die nächste Generation von Rohrformanlagen dar, die die Produktionsvielseitigkeit und betriebliche Effizienz weiter steigern wird.

Nachhaltigkeit und Umweltaspekte

Die ökologische Nachhaltigkeit gewinnt bei Herstellungsentscheidungen immer stärker an Bedeutung, und moderne Rohrformmaschinen werden unter den Gesichtspunkten Energieeffizienz und Abfallreduzierung konzipiert. Fortschrittliche Antriebssysteme, optimierte Umformprozesse und intelligente Steuerungsalgorithmen arbeiten zusammen, um den Energieverbrauch zu minimieren und gleichzeitig die Produktionsleistung zu maximieren. Die präzisen Steuerungsmöglichkeiten verringern zudem Materialabfälle, indem sie Ausschuss während der Rüstphase reduzieren und die Erfolgsquote beim Erstdurchlauf verbessern.

Die Vielseitigkeit moderner Rohrformmaschinen trägt zu Nachhaltigkeitszielen bei, indem sie Herstellern ermöglicht, Produktionsabläufe zu konsolidieren und die Gesamtanzahl an Maschinen für unterschiedliche Produktionsanforderungen zu reduzieren. Diese Konsolidierung verringert den gesamten Energieverbrauch, den Wartungsaufwand und den benötigten Produktionsflächenbedarf, während gleichzeitig die Produktionskapazitäten erhalten oder verbessert werden. Die ökologischen Vorteile unterstützen unternehmensinterne Nachhaltigkeitsinitiativen und bieten gleichzeitig wirtschaftliche Vorteile durch niedrigere Betriebskosten.

FAQ

Welche Materialien können mit einer Rohrformmaschine verarbeitet werden?

Moderne Rohrformmaschinen können eine breite Vielfalt an Materialien verarbeiten, darunter Kohlenstoffstahl, Edelstahl, Aluminium, Kupfer und verschiedene Speziallegierungen. Die spezifischen verarbeitbaren Materialien hängen von den Konstruktionsspezifikationen der Maschine, den Umformkraftfähigkeiten und den verfügbaren Werkzeugoptionen ab. Die meisten Maschinen können Materialdicken von dünnen Blechen bis hin zu dickwandigen Anwendungen verarbeiten, wobei einige Spezialsysteme für bestimmte Materialtypen oder Größenbereiche ausgelegt sind.

Wie schnell kann die Produktion zwischen verschiedenen Rohrspezifikationen umgestellt werden?

Die Umstellzeit hängt von der spezifischen Maschinenkonstruktion und dem Grad der Unterschiede zwischen den Spezifikationen ab. Moderne Maschinen mit programmierbaren Steuerungen und automatisierten Einstellsystemen können typischerweise innerhalb weniger Minuten statt Stunden zwischen gespeicherten Programmen wechseln. Bei einfachen Durchmesseränderungen innerhalb des Maschinenbereichs können die Umstellungen nur 15 bis 30 Minuten dauern. Komplexere Änderungen, die unterschiedliche Materialien oder erhebliche dimensionsmäßige Abweichungen beinhalten, erfordern möglicherweise zusätzliche Zeit für Werkzeugeinstellungen und die Überprüfung des Setups.

Welche Qualitätskontrollmaßnahmen sind in moderne Rohrformsysteme integriert?

Moderne Rohrformmaschinen verfügen über mehrere Qualitätskontrollfunktionen, darunter die Echtzeit-Überwachung der Abmessungen, die Prüfung der Oberflächenqualität und die Verfolgung von Prozessparametern. Fortschrittliche Systeme umfassen Laser-Messgeräte, Ultraschall-Dickenmessgeräte und Bildinspektionssysteme, die die Produktqualität während der Produktion kontinuierlich überwachen. Automatisierte Datenaufzeichnung und Funktionen zur statistischen Prozessregelung ermöglichen eine umfassende Dokumentation der Qualität sowie Trendanalysen für kontinuierliche Verbesserungsmaßnahmen.

Wie unterscheidet sich eine Rohrformmaschine von anderen Rohrherstellungsverfahren?

Rohrformmaschinen bieten erhebliche Vorteile gegenüber alternativen Herstellungsverfahren, darunter eine überlegene Maßhaltigkeit, höhere Produktionsraten und niedrigere Stückkosten bei mittleren bis hohen Produktionsmengen. Im Vergleich zur nahtlosen Rohrherstellung bieten gefertigte Rohre bei geringeren Kosten ausgezeichnete Festigkeitseigenschaften sowie eine größere dimensionsmäßige Flexibilität. Die Möglichkeit der kontinuierlichen Produktion und die geringen Rüstzeiten machen die Rohrformung ideal für Anwendungen, die eine gleichbleibende Qualität und eine effiziente Produktion verschiedener Spezifikationen erfordern.

Inhaltsverzeichnis

- Grundlagen der Rohrformtechnologie verstehen

- Produktionsvielfalt und betriebliche Vorteile

- Qualitätskontrolle und Präzisionsfertigung

- Wirtschaftliche Vorteile und Rendite der Investition

- Künftige Trends und technologische Entwicklungen

-

FAQ

- Welche Materialien können mit einer Rohrformmaschine verarbeitet werden?

- Wie schnell kann die Produktion zwischen verschiedenen Rohrspezifikationen umgestellt werden?

- Welche Qualitätskontrollmaßnahmen sind in moderne Rohrformsysteme integriert?

- Wie unterscheidet sich eine Rohrformmaschine von anderen Rohrherstellungsverfahren?