Manufacturing businesses across industries are increasingly recognizing the strategic importance of investing in advanced tube production equipment. The decision to integrate an erw tube mill into your production line represents a significant capital investment that requires careful consideration of multiple operational factors. Understanding the technical capabilities, production requirements, and economic implications of tube mill technology can help manufacturers make informed decisions about their equipment investments. Modern erw tube mill systems offer sophisticated solutions for producing high-quality welded tubes that meet stringent industry standards while maintaining competitive production costs.

Understanding ERW Tube Mill Technology

Core Manufacturing Principles

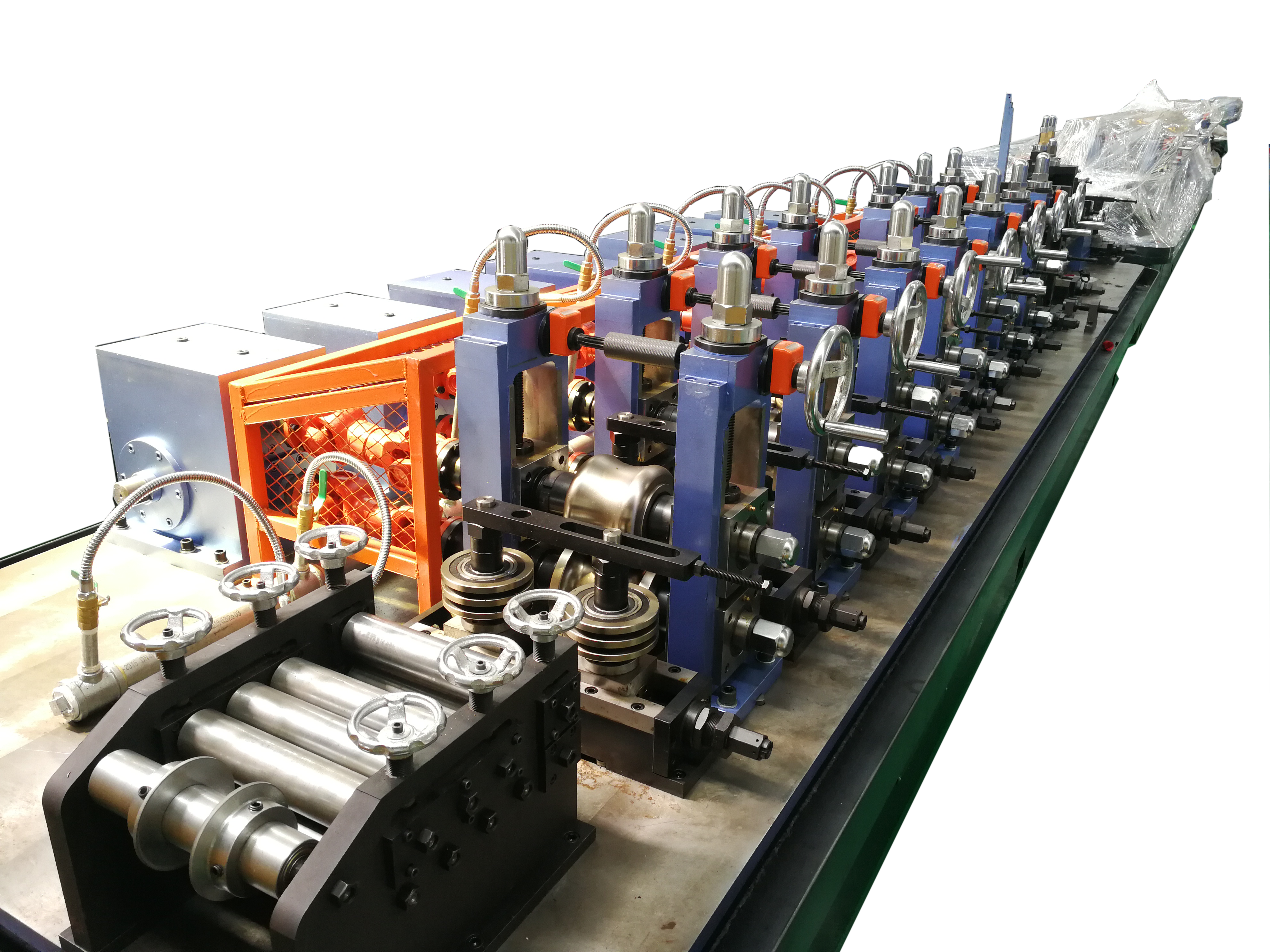

Electric Resistance Welding technology represents the foundation of modern tube manufacturing processes. An erw tube mill utilizes high-frequency electrical current to create precise welds along the longitudinal seam of formed steel strips. This manufacturing approach enables consistent production of welded tubes with excellent dimensional accuracy and mechanical properties. The process begins with steel coil preparation, where raw materials undergo careful inspection and surface treatment to ensure optimal welding conditions.

The forming section of an erw tube mill progressively shapes flat steel strips into cylindrical profiles through a series of precisely calibrated forming rolls. Advanced control systems monitor material thickness, strip width, and forming speeds to maintain consistent tube geometry throughout production runs. Temperature control during the welding process ensures proper heat input for achieving strong, reliable weld joints that meet industry specifications for pressure applications and structural requirements.

Production Capabilities and Specifications

Modern erw tube mill equipment offers remarkable flexibility in tube diameter ranges and wall thickness specifications. Most industrial-grade systems can produce tubes ranging from small diameter applications to large structural profiles, accommodating diverse market demands within a single production line. The precision engineering of contemporary tube mills enables manufacturers to maintain tight tolerances on dimensional specifications while achieving high production speeds that optimize manufacturing efficiency.

Quality control integration represents a critical aspect of erw tube mill operations, with advanced systems incorporating real-time monitoring of weld integrity, dimensional accuracy, and surface finish. Automated inspection systems can detect potential defects during production, enabling immediate corrections that minimize waste and ensure consistent product quality. These technological advances have significantly improved the reliability and performance characteristics of ERW-produced tubes across various industrial applications.

Business Applications and Market Opportunities

Industrial Sector Requirements

Construction and infrastructure development sectors represent substantial market opportunities for businesses operating an erw tube mill. Steel tubes produced through ERW processes serve critical functions in building frameworks, pipeline systems, and mechanical structures that require reliable performance under various load conditions. The growing demand for sustainable construction materials has increased interest in high-quality welded tubes that offer superior strength-to-weight ratios compared to traditional structural alternatives.

Automotive and transportation industries continue expanding their utilization of ERW tubes for chassis components, exhaust systems, and hydraulic applications. The precise dimensional control achievable with modern erw tube mill technology enables manufacturers to meet strict automotive specifications while maintaining cost-effective production volumes. Energy sector applications, including oil and gas pipeline infrastructure, require tubes that can withstand high pressure and corrosive environments, making ERW technology particularly suitable for these demanding applications.

Market Positioning and Competitive Advantages

Establishing a competitive position in the tube manufacturing market requires understanding the unique advantages that erw tube mill technology provides over alternative production methods. ERW tubes typically offer superior cost-effectiveness compared to seamless tube production while maintaining excellent mechanical properties suitable for most industrial applications. The ability to produce consistent quality at high production speeds enables manufacturers to respond effectively to fluctuating market demands and customer requirements.

Geographic market considerations play important roles in determining the viability of erw tube mill investments for specific business operations. Regional infrastructure development projects, local industrial growth patterns, and proximity to raw material suppliers can significantly influence the profitability of tube manufacturing ventures. Understanding these market dynamics helps businesses identify optimal timing for equipment investments and production capacity expansion strategies.

Economic Considerations and Investment Analysis

Initial Capital Requirements

The financial commitment associated with acquiring an erw tube mill encompasses multiple cost components beyond the primary equipment purchase. Installation expenses, facility preparation, utility infrastructure, and operator training programs represent significant additional investments that must be factored into comprehensive project budgets. Modern tube mill systems require specialized electrical power configurations, cooling water systems, and material handling equipment that may necessitate facility modifications or upgrades.

Raw material supply agreements and inventory management strategies significantly impact the operational economics of erw tube mill operations. Steel coil procurement represents the largest variable cost component in tube manufacturing, making supplier relationships and pricing agreements critical factors in maintaining competitive production costs. Businesses must evaluate local steel availability, transportation costs, and quality specifications when assessing the economic viability of tube mill investments in specific geographic markets.

Return on Investment Projections

Calculating realistic return on investment projections for erw tube mill operations requires careful analysis of market demand patterns, pricing trends, and production capacity utilization rates. Historical market data indicates that tube manufacturing businesses typically achieve positive cash flow within eighteen to thirty-six months of operation, depending on market conditions and operational efficiency levels. Production volume planning must account for seasonal demand variations and long-term market growth projections to ensure sustainable profitability.

Operating cost optimization strategies can significantly improve the financial performance of erw tube mill investments through enhanced efficiency and reduced waste generation. Energy consumption management, preventive maintenance programs, and quality control improvements contribute to lower per-unit production costs while maintaining product quality standards. These operational improvements typically compound over time, resulting in improved profit margins and enhanced competitive positioning within target markets.

Technical Implementation and Setup Requirements

Facility Infrastructure Considerations

Successful erw tube mill implementation requires comprehensive facility planning that addresses space requirements, material flow logistics, and safety considerations. Production floor layouts must accommodate raw material storage areas, tube mill equipment positioning, finished product handling systems, and quality control inspection stations. Adequate ceiling heights and structural support capabilities are essential for proper installation of overhead material handling equipment and ventilation systems required for safe operations.

Electrical infrastructure requirements for erw tube mill operations typically exceed standard industrial power configurations due to the high-frequency welding systems and precision control equipment. Three-phase power supplies with appropriate voltage regulation and harmonic filtering capabilities ensure stable operation of sensitive electronic components. Backup power systems may be necessary to prevent production interruptions and protect expensive equipment from power quality issues that could result in costly repairs or recalibration requirements.

Workforce Development and Training

Operating an erw tube mill requires skilled technicians who understand both mechanical systems and electronic control technologies. Comprehensive training programs must address equipment operation procedures, quality control protocols, safety requirements, and troubleshooting techniques that enable efficient production management. Many equipment manufacturers provide specialized training services that help businesses develop internal expertise while minimizing the learning curve associated with new technology implementation.

Ongoing workforce development initiatives contribute to sustained operational excellence and continuous improvement in production efficiency. Regular training updates on new technologies, safety protocols, and quality standards help maintain high performance levels while reducing the risk of accidents or equipment damage. Establishing internal training capabilities enables businesses to maintain consistency in operations and reduce dependence on external technical support services over time.

Quality Control and Standards Compliance

Industry Standards and Certifications

Modern erw tube mill operations must comply with numerous industry standards and quality certifications that ensure product reliability and market acceptance. International standards such as ASTM, API, and ISO specifications define dimensional tolerances, mechanical properties, and testing requirements for welded tubes used in various applications. Maintaining compliance with these standards requires robust quality management systems and regular third-party auditing to verify production capabilities and quality control effectiveness.

Documentation requirements for quality certification programs necessitate comprehensive record-keeping systems that track material traceability, production parameters, and test results for each production lot. Electronic data management systems integrated with erw tube mill control systems can automate much of this documentation process while ensuring accuracy and completeness of quality records. These systems also facilitate rapid response to customer inquiries and regulatory compliance requirements that may arise during product service life.

Testing and Inspection Protocols

Implementing effective testing and inspection protocols throughout the erw tube mill production process helps identify potential quality issues before they impact finished products. Non-destructive testing methods, including ultrasonic inspection and electromagnetic testing, can detect weld defects and material inconsistencies without damaging produced tubes. Statistical process control techniques help maintain consistent quality levels while optimizing production efficiency and minimizing waste generation.

Advanced inspection technologies integrated with modern erw tube mill systems provide real-time feedback on production quality and enable immediate corrections when deviations occur. Automated measurement systems can monitor dimensional accuracy, surface finish quality, and weld integrity throughout production runs. These technologies significantly reduce the need for manual inspection while improving overall product consistency and customer satisfaction levels.

FAQ

What production volumes can be achieved with an erw tube mill?

Production volumes for an erw tube mill typically range from 20,000 to 150,000 tons annually, depending on equipment size, tube specifications, and operational efficiency. Smaller mills focused on specialty applications may produce 20,000-50,000 tons per year, while large-scale industrial systems can exceed 100,000 tons annually. Actual production rates depend on tube diameter, wall thickness, material grades, and the number of operating shifts per day. Most manufacturers achieve optimal efficiency with continuous operation schedules that maximize equipment utilization while maintaining quality standards.

How long does erw tube mill installation typically take?

Complete erw tube mill installation and commissioning typically requires 4-8 months from equipment delivery to full production capability. This timeline includes foundation preparation, equipment installation, utility connections, calibration, and operator training. Complex installations with extensive automation or custom specifications may require additional time for system integration and testing. Proper project planning and coordination with equipment suppliers can help minimize installation time while ensuring proper system functionality and safety compliance.

What maintenance requirements should be expected for erw tube mill operations?

Regular maintenance for an erw tube mill includes daily lubrication checks, weekly forming roll inspection, monthly calibration verification, and quarterly major component servicing. Critical components such as welding electrodes, forming rolls, and drive systems require scheduled replacement based on production volumes and wear patterns. Preventive maintenance programs typically reduce unexpected downtime by 60-80% compared to reactive maintenance approaches. Most manufacturers recommend maintaining spare parts inventory equivalent to 3-6 months of normal wear components to minimize production interruptions.

What raw material specifications are required for optimal erw tube mill performance?

Optimal erw tube mill performance requires steel coils with consistent thickness tolerance (±0.05mm), clean surface conditions, and appropriate mechanical properties for the intended application. Steel grades typically range from low-carbon structural steels to high-strength alloys, depending on end-use requirements. Coil width accuracy, edge quality, and surface finish significantly impact production efficiency and final tube quality. Material suppliers should provide detailed chemical analysis and mechanical property certification to ensure compatibility with specific erw tube mill configurations and welding parameters.