máquina de alta calidad para fabricar tubos ms

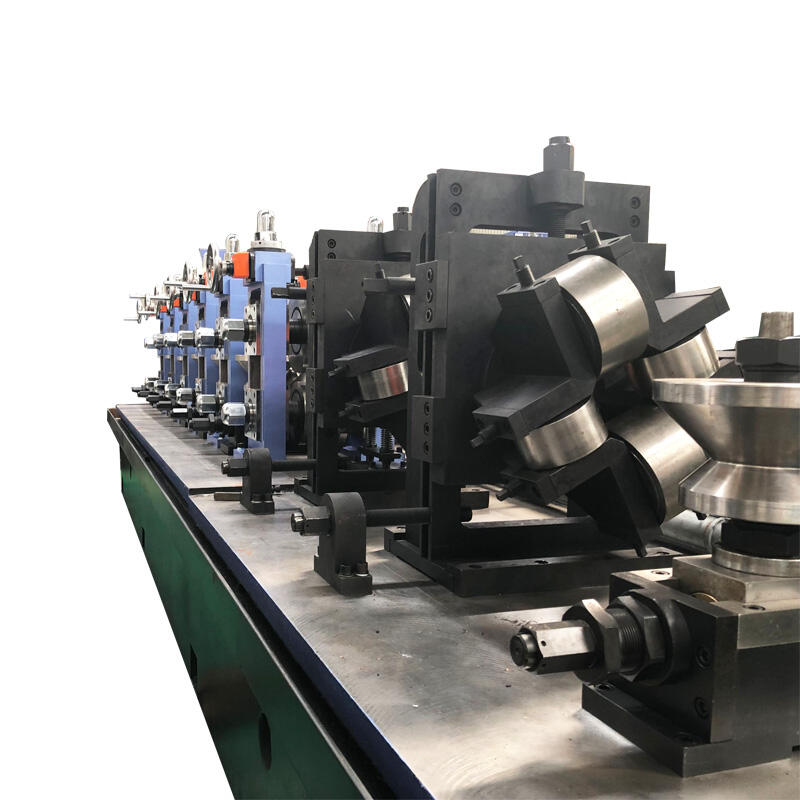

La máquina de alta calidad para fabricar tubos MS representa un hito de la tecnología de fabricación moderna, diseñada para producir tubos de acero dulce con una precisión y fiabilidad excepcionales. Este equipo avanzado integra sistemas de automatización de vanguardia con componentes mecánicos robustos para ofrecer capacidades de producción ininterrumpida. La máquina cuenta con un sofisticado sistema de formado por rodillos que gradualmente da forma a tiras de acero planas en tubos cilíndricos perfectos, manteniendo una precisión dimensional estricta durante todo el proceso. Su estación de soldadura precisa emplea tecnología de alta frecuencia para crear juntas fuertes y uniformes que cumplen con los estándares de calidad internacionales. El diseño versátil de la máquina permite acomodar varios tamaños de tubos, normalmente con un rango de diámetro de 20mm a 76mm y espesores de pared de 0.5mm a 3mm. El sistema integrado de control de calidad monitorea continuamente los parámetros de producción, incluyendo la temperatura de soldadura, la presión de formado y la velocidad de línea, asegurando una calidad de salida consistente. Los controles PLC avanzados permiten a los operadores ajustar los ajustes con precisión, mientras que la interfaz amigable simplifica las operaciones y procedimientos de mantenimiento. La construcción robusta de la máquina, que incluye componentes de acero de alta calidad y partes ingenierizadas con precisión, garantiza una fiabilidad a largo plazo y un mínimo tiempo de inactividad. Este equipo es particularmente valioso en industrias que requieren una producción en gran volumen de tubos MS para construcción, fabricación de muebles, componentes automotrices y aplicaciones estructurales.