osta alennettuja gi-putkien valmistuslaitteita

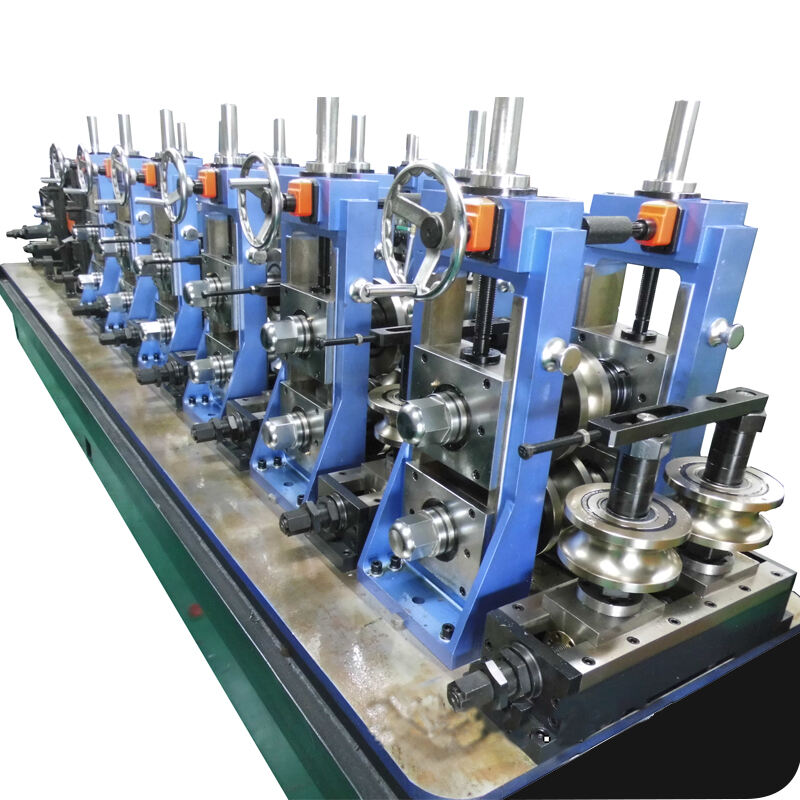

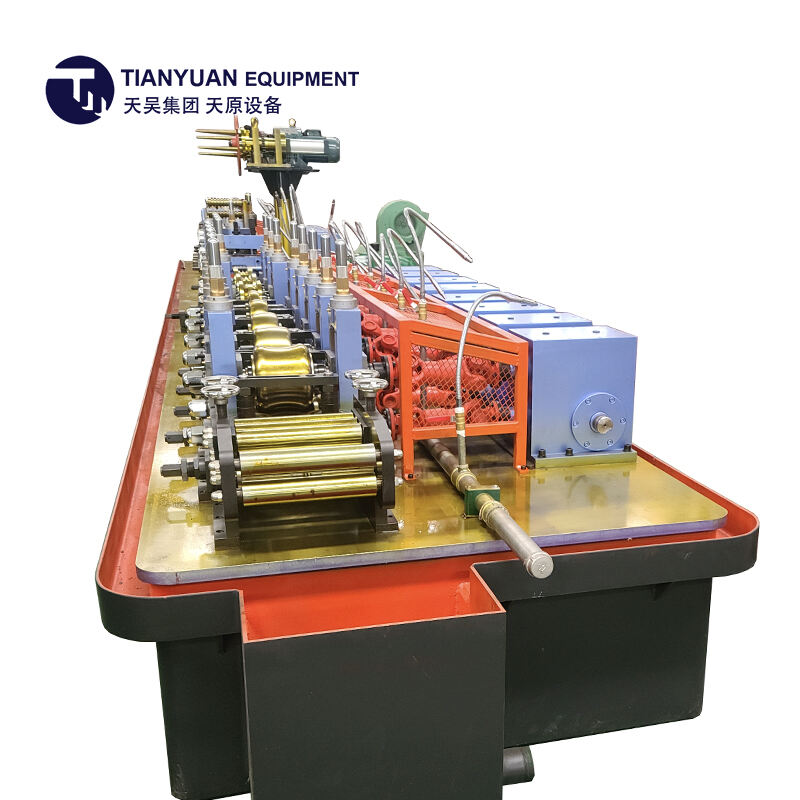

Ostotyypin alennus GI putkien valmistuslaite edustaa huippuluokan ratkaisua galvanisoitujen rautasilmalaitteiden tehokkaan ja taloudellisen valmistuksen kannalta. Tämä edistyksillinen valmistussysteemi sisältää vallitsevinta teknologiaa, joka muuntaa raaka-aineet korkealaatuisiksi GI-silmalaitteiksi yksinkertaisessa prosessissa. Laite varustettu tarkoja ohjaimia ja automatisoituja toimintoja mahdollistaa vakaiden silmien tuotannon tasaisella seiniptyvylällä ja erinomaisella pinnan laadulla. Se käyttää kehittyneitä muotoilujärjestelmiä, jotka sisältävät avoimet, tasaus- ja liitosasemat sekä tarkkoja koonmuutos- ja leikkausmekanismeja. Laite voi käsitellä erilaisia putken mittoja, tyypillisesti 1/2 tuumasta 8 tuumaan halkaisijaksi, mukautettavilla seinän paksuusvaihtoehdoilla. Integroitu laadunhallintajärjestelmä varmistaa, että jokainen putki täyttää teollisuuden standardit kestävyydestä ja korrosiorkestyksestä. Tämä monipuolinen kone on suunniteltu jatkuvaan toimintaan, tarjoamalla korkean tuotantokapasiteetin samalla kun säilyttää energiatehokkuuden. Sen käyttäjäystäväliittymä antaa käyttäjille mahdollisuuden helposti säätää parametreja ja seurata tuotantomittauksia reaaliajassa, varmistamalla optimaalisen suorituskyvyn ja minimoidun pysähdyksen.