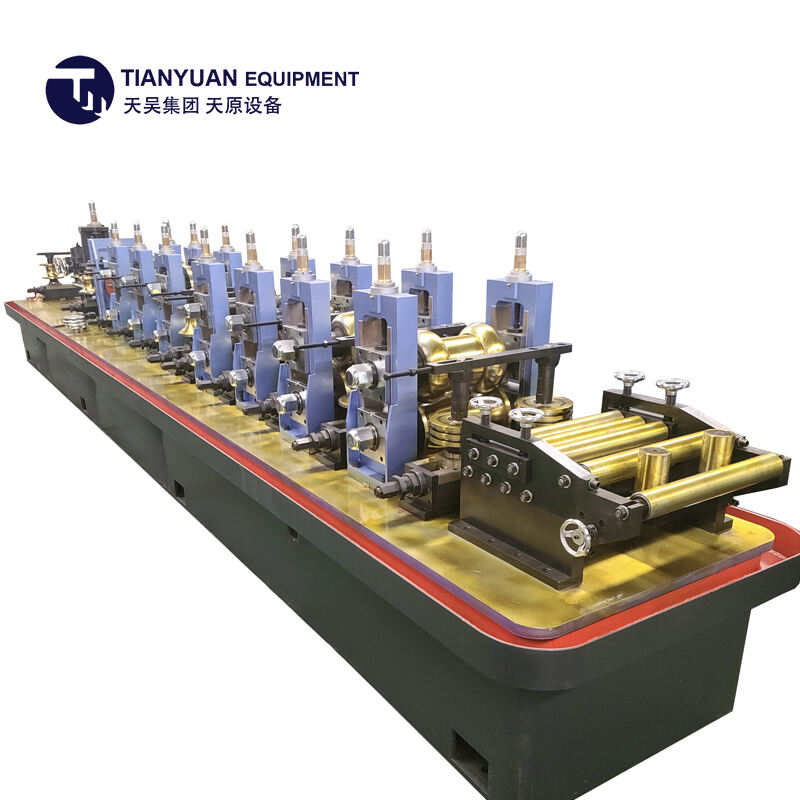

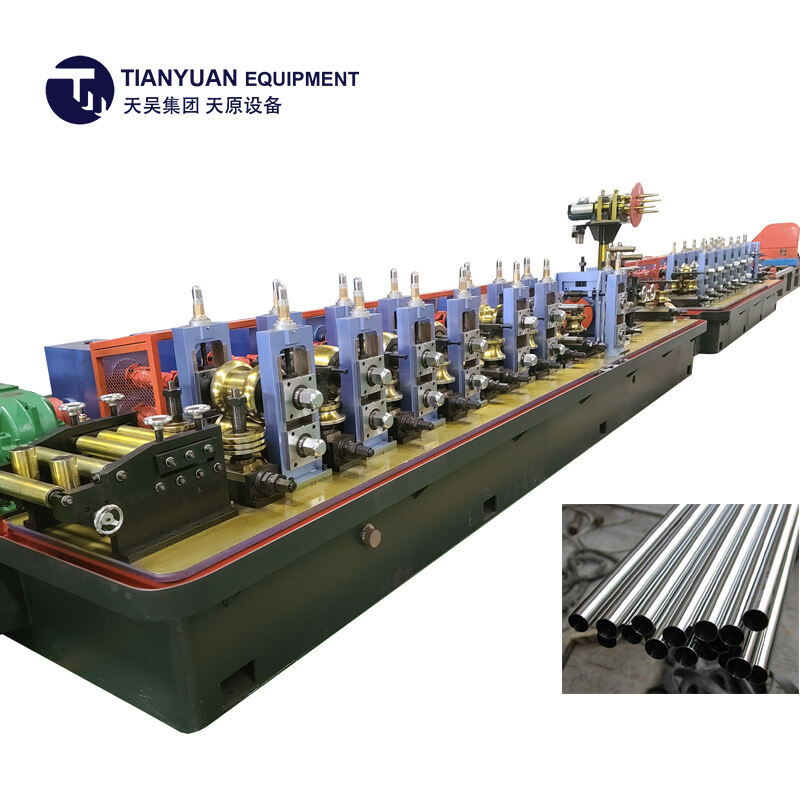

hf liimattu putkemylly tehdas

HF liimattu putkitehdas edustaa huippuluokan valmistusyksikköä, joka on omistettu tarkkaan ja tehokkaasti tuottamaan korkean taajuuden liimattuja teräsputkia. Tämä kehittynevä yksikkö sisältää viimeisintä teknologiaa, joka mahdollistaa jatkuvan putkien valmistuksen monimutkaisen prosessin kautta, joka koostuu levyjen muotoilusta, korkeataajuusliimauksesta ja liimausjälkeisestä käsittelemisestä. Tehtaassa käytetään automatisoituja järjestelmiä ja tietokoneohjattuja toimintoja, jotka säilyttävät vakionlaatun hyvin valmistuslinjan kautta. Kattavalla asetuksellaan tehdas hallitsee kaikkea alusta loppuun, alkaen raaka-aineiden käsittelystä ja päättyen lopulliseen tuotteen tarkastukseen, varmistaen, että jokainen putki täyttää ankariin teollisuuden standardit. Valmistusprosessi alkaa teräslevyn käsittelystä, jonka jälkeen tarkat muotoilutoiminnot luovat putkien muodon. Korkeataajuusliimausasema, joka on keskipiste operaatioiden keskuudessa, käyttää elektromagneettista induktiota luodakseen vahvoja ja luotettavia liimauksia hämmästyttävissä nopeuksissa. Laadunvalvontapisteissä on edistynyttä testauslaitetta, mukaan lukien ulträsy- ja sähkövirtatestausjärjestelmiä, jotka vahvistavat jokaisen liimauksen kokonaisuuden. Tehtaalla on myös erikoistuneita koonmuutos- ja suoritusjärjestelmiä sekä leikkaussysteemejä, jotka varmistavat tarkat pituusmääritykset. Modernit pakkaus- ja varastoratkaisut sulkevat valmistuskyklyn, valmistelemaan valmiit putkit turvalliseen kuljetukseen asiakkaille ympäri maailmaa.