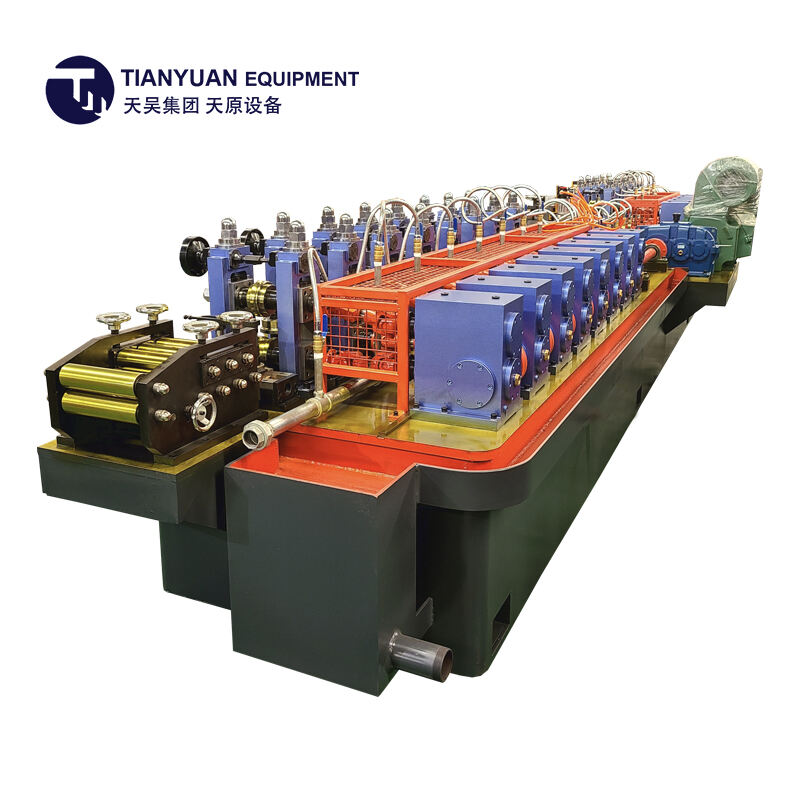

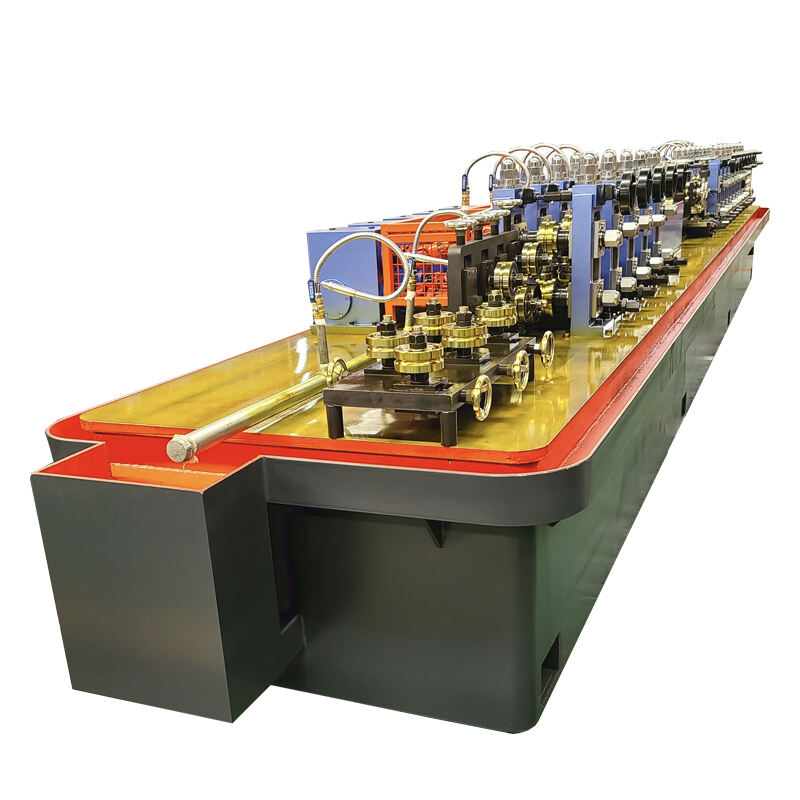

korkealaatuisessa hf-lasitetussa putkien valmistuslaitoksessa

Korkealaatuinen HF liimattu putkitehdas edustaa huippuluokan valmistussuunnitelmaa, joka yhdistää tarkkaa insinöörityötä kehittyneiden teknologioiden kanssa tuottamaan erinomaisia liimatettuja putteja. Tämä huippulaatuisi tehdas käyttää korkean taajuuden induktioviilintä teknologiaa luodakseen naulattomia sidoksia metalliset putket varmistamalla poikkeuksellisen rakenteellisen kokonaisuuden ja kestävyyden. Tehtaassa on otettu käyttöön automatisoidut ohjausjärjestelmät, jotka säilyttävät vakaita viilintyyppejä koko tuotantoprosessin ajan, mikä johtaa tasaiseen viilien laatuun ja mitalliseen tarkkuuteen. Laitos sisältää edistyneitä materiaalin käsittelyjärjestelmiä, hienosäätetyjä muotoilulaitteita ja tarkkoja laadunvalvontamekanismeja, jotka toimivat yhdessä tuottamaan putteja, jotka täyttävät ankariin kansainvälisiin standardeihin. Tehtaan monipuoliset tuotantokyvyt sopivat erilaisille putken mitoille, alkaen pienimmistä halkaisijista suurimpia teollisia putkia, kun taas seinän paksuudet ohjataan tarkasti vastaamaan sovelluksen vaatimuksia. Sen moderni suunnittelu sisältää reaaliaikaiset seurantajärjestelmät, jotka seuraavat tuotantoparametreja, mahdollistamalla välitöntä säätöä ja optimointia viilintäprosessissa. Laitos integroi myös laajat testauslaitteet sekä tuhoavia että ei-tuhoavia tutkimuksia lopullisten tuotteiden tarkastamiseksi, varmistaakseen, että jokainen putki täyttää ankariin laadunormeihin ennen kuin se lähtee tuotannosta.