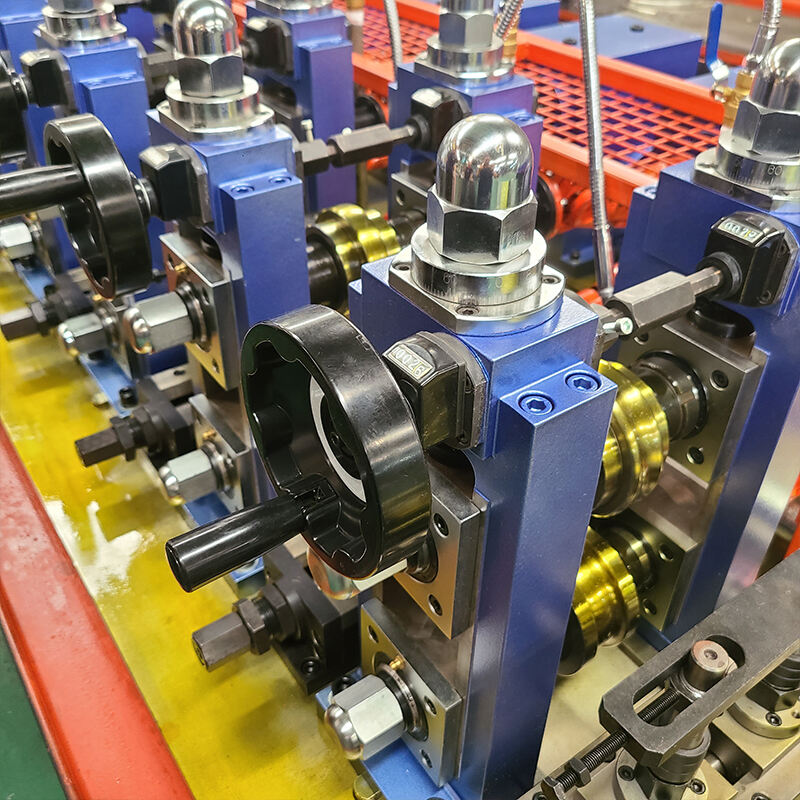

चीन में बनाई गई एचएफ वेल्डेड पाइप मिल

चीन में बनाई गई HF वेल्डेड पाइप मिल एक नवीनतम विनिर्माण समाधान है जो शुद्ध अभियांत्रिकी को लागत-प्रभावी उत्पादन क्षमता के साथ मिलाता है। इस उन्नत उपकरण का उपयोग उच्च-बारंबार वेल्डिंग प्रौद्योगिकी का उपयोग करके विभिन्न औद्योगिक अनुप्रयोगों के लिए उपयुक्त अटूट और स्थायी पाइप बनाने के लिए किया जाता है। मिल में नवीनतम नियंत्रण प्रणाली होती है जो उत्पादन प्रक्रिया के दौरान निरंतर वेल्ड गुणवत्ता और आयामी सटीकता को यकीनन करती है। उत्पादन गति 20-120m/मिनट की श्रृंखला में होती है, जो पाइप विनिर्माण की विनिर्दिष्टियों पर निर्भर करती है, और ये मिल 12mm से 219mm तक के व्यास और 0.4mm से 8mm तक की दीवार मोटाई वाले पाइप को दक्षतापूर्वक बना सकती है। प्रणाली में स्वचालित साइजिंग स्टेशन, शुद्ध फॉर्मिंग यूनिट्स और उन्नत वेल्डिंग मैकेनिज़्म्स शामिल हैं जो उत्कृष्ट उत्पाद गुणवत्ता का वचन देते हैं। उन्नत विशेषताओं में डिजिटल मॉनिटरिंग प्रणाली, स्वचालित तापमान नियंत्रण और वास्तविक समय में गुणवत्ता जाँच क्षमता शामिल है। ये मिल कार्बन स्टील, स्टेनलेस स्टील और एल्यूमिनियम स्टील जैसी विभिन्न सामग्रियों को संभालने के लिए डिज़ाइन की गई हैं, जिससे वे विभिन्न उद्योग आवश्यकताओं के लिए बहुमुखी होती है। PLC नियंत्रण प्रणाली की एकीकरण सुरक्षित संचालन और न्यूनतम बंद रहने की सुनिश्चित करती है, जबकि एर्गोनॉमिक डिजाइन आसान रखरखाव और संचालन को बढ़ावा देता है।