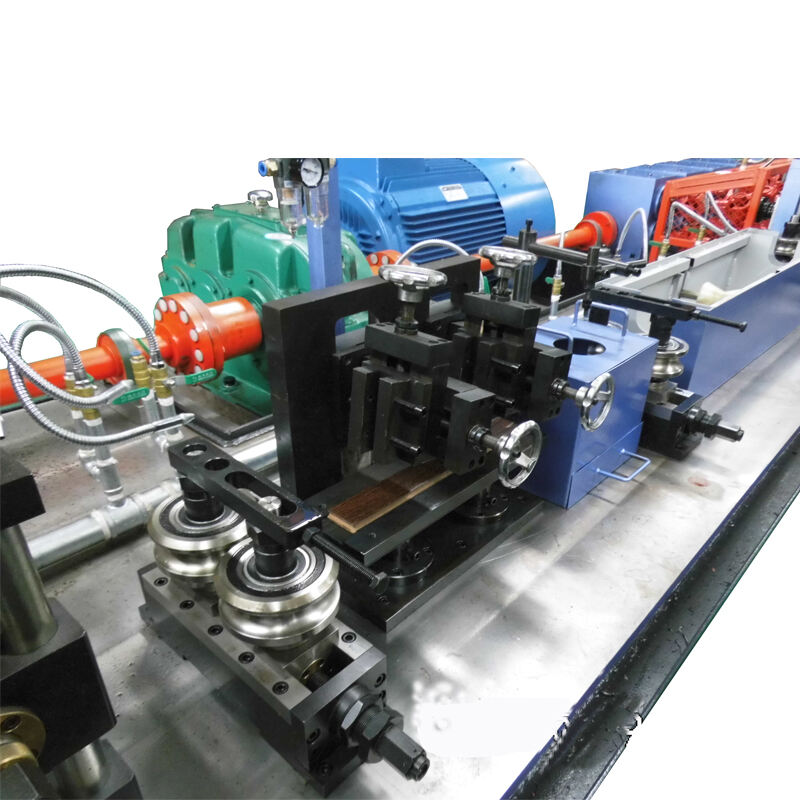

պատվածով գի տուբեր սարքող մաքինա

Պարտադիրված GI կողմերունք սարքող մաքինային համակարգը ներկայացնում է ստորագրություններով լուծում մետաղական կողմերունքների սարքման մեջ, որը ձևավորված է բարձր որակի գալվանացված արկանագիտական կողմերունքներ սարքելու համար՝ ճշգրտությամբ և արդյունավետությամբ։ Այս առաջատար սարքման համակարգը ինտեգրում է բազմաթիվ սարքման փուլեր՝ սկսած սկզբնական նյութից մինչև ավարտական արտադրանքի ստորագրությունը՝ ստրուկտուրային ավտոմատացված գործընթացով։ Մաքինան հանդիսանում է ժամանակակից ձևավորման տեխնոլոգիա՝ որը համոզում է ստանդարտ կողմերունքի տրամագիծ և պատի հաստությունը ամբողջ սարքման ընթացքում։ Նրա համակարգային կառավարման համակարգը թույլ է տալիս օպերատորներին իրականավորության մեջ փոխել պարամետրերը՝ պահպանելով արտադրանքի որակը և արդյունավետությունը առավելացնելով։ Մաքինան կարող է սպասարկել տարբեր կողմերունքների սպեցիֆիկացիաներ՝ սովորաբար սարքելով կողմերունքներ՝ տրամագծով կես անցկացից մինչև 8 անցկացին, իսկ պատի հաստությունը՝ 1.2մմ-ից մինչև 6մմ։ Ավտոմատացված համակարգի հետ ավելացված ավտոմատացված համակցումների համակարգը օգտագործում է բարձր հաճախության համակցումների տեխնոլոգիա՝ ստեղծելով ուժեղ և հաստատուն համակցումներ։ Ինտեգրացված գալվանացումի գործընթացը համոզում է գերակայություններով կորոզիայի դիմադրություն՝ երկարանալով ավարտական արտադրանքի կյանքը։ Որակի կառավարման մե커նիզմները, ներառյալ ուլտրասաウնդային տեստավորումներ և տեսական ստորագրության համակարգերը, ինտեգրված են՝ համոզելու համար, որ յուրաքանչյուր կողմերունք համապատասխանում է արդյունաբերության ստանդարտներին։ Այս բազմանմուշ համակարգը համարվում է համարյալ կողմերունքների սարքման համար՝ օգտագործվող սարքում կառուցապես, ջրամունքի տարածման, գազի տարածման և տարբեր արդյունաբերության կիրառություններում։