մանգական ձող ձևավորման մաքինայի սահմանողներ

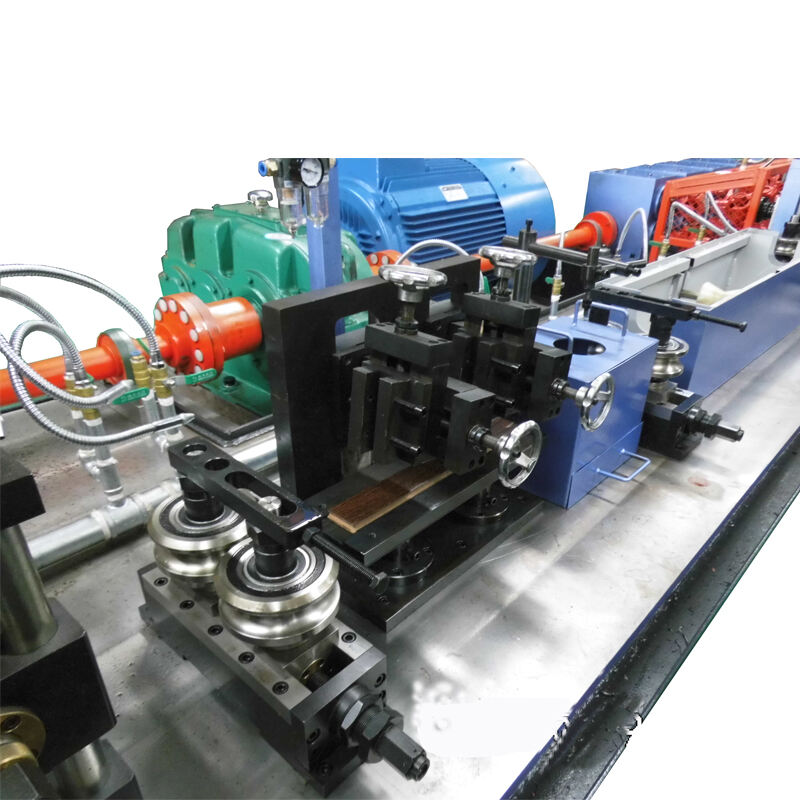

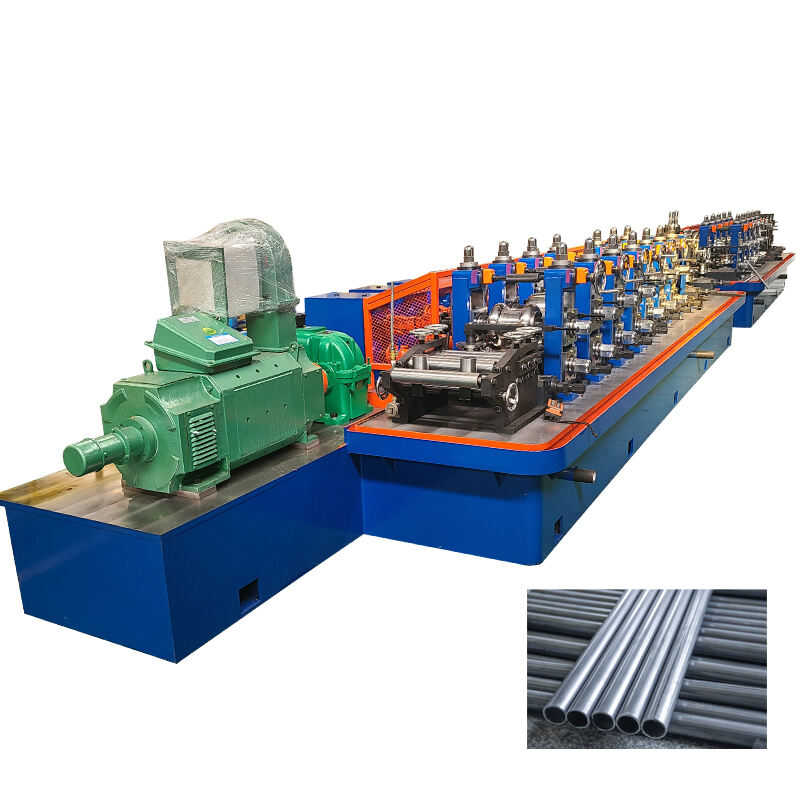

Ալիքների ձևավորման մաքսային հարկավոր բաժնին ներկայացնում են գործարանային արդյունաբերության մեջ, առաջարկում են առաջատար համակարգեր, որոնք պատրաստված են արդյունավետ և ճշգրիտ ձևավորելու բարձր որակի ալիքներ: Այդ հարկավորները առաջարկում են ամբողջական լուծումներ տարբեր արդյունաբերությունների համար, ներառյալ կառուցական, ավտոմոբայլի և ինֆրաստրուկտուրայի զարգացում: Նրանց մաքսայինները օգտագործում են առաջատար տեխնոլոգիաներ՝ փոխարինելու հարթ մետաղական սանդերը կատարյալորեն ձևավորված ալիքներին սկսական գործողությունների շարքով՝ կապում, հանգույց և ավարտական գործողությունների միջոցով: Ավանդական ալիքների ձևավորման մաքսայինները բավարարում են ավտոմատացված կառավարման համակարգերին, ճշգրիտ չափումների համակարգերին և բազմաթիվ ձևավորման ստացիոնարներին, որոնք համոզված են ապահովելու անընդհատ արտադրանքի որակ: Այդ հարկավորները նաև առաջարկում են պարամետրացված լուծումներ՝ բավարարելու տվյալ արտադրանքային պահանջներին, փոքր տրամագրով ալիքներից մինչև մեծ արդյունաբերության տուբեր: Մաքսայինները հավաքված են առաջատար հատկություններով՝ ավտոմատ չափսերի փոխարինման, իրական ժամանակի հետ համարումների համակարգերի և որակի կառավարման մեխանիզմների միջոցով: Ավելի նախկին հարկավորները նաև առաջարկում են լայն հետապահանջային հաջորդագրություն՝ ներառյալ պահումի ծառայություններ, արտադրանքային մասերի հասանելիություն և տեխնիկական ուսուցում օպերատորներին: Այդ մաքսայինները ներառում են անվտանգության հատկություններ և համաձայնացված են միջազգային արդյունաբերության ստանդարտների հետ՝ ապահովելու և օպերատորի անվտանգությունը, և արտադրանքի որակը: Ամենաշատ հարկավորները նաև առաջարկում են ամբողջական ապահովություններ և տեխնիկական փաստաթղթեր՝ ապահովելու անընդհատ աշխատանք և պահում: