Ժամանակակից խողովակների արտադրության տեխնոլոգիայի էվոլյուցիան

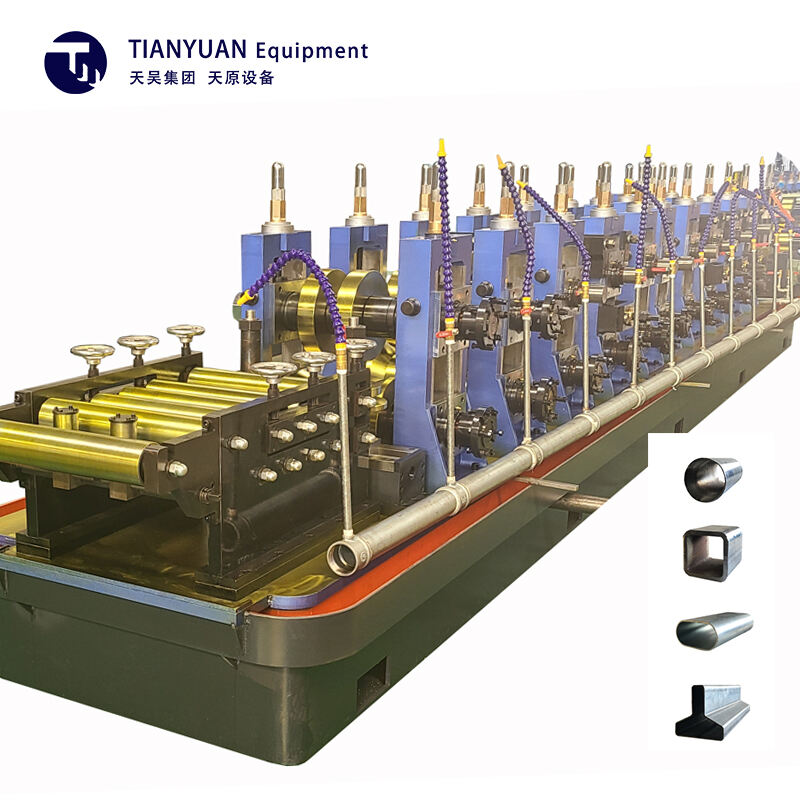

Արտադրական համակարգը փորձել է նշանակալի փոփոխություններ տասնամյակների ընթացքում, և ամենակարևոր առաջընթացներից մեկը հենց HF կամրջակային խողովակների գործարանների . Այս բարդ արտադրական սարքավորումները խողովակների արտադրության արդյունավետության գագաթնակետն են ներկայացնում՝ միավորելով ճշգրիտ ինժեներական լուծումներ բարձր հաճախականությամբ լարվածքային տեխնիկայի հետ՝ ստեղծելով անընդհատ և ամուր խողովակներ տարբեր արդյունաբերական կիրառությունների համար:

Ժամանակակից HF էլեկտրական հաղորդմամբ փակ խողովակների գործարանները միավորում են առաջատար ավտոմատացում, իրական ժամանակում հսկման համակարգեր և արտադրության առաջադեմ տեխնոլոգիաներ՝ արտադրելով խողովակներ, որոնք համապատասխանում են աճող պահանջներին արդյունաբերության ստանդարտների նկատմամբ: Քանի որ գլոբալ ենթակառուցվածքների զարգացումը շարունակում է աճել, այս կայանները կարևոր դեր են խաղում բարձրորակ էլեկտրական հաղորդմամբ փակ խողովակների աճող պահանջարկը բավարարելու գործում:

HF էլեկտրական հաղորդմամբ փակ խողովակների արտադրության հիմնական բաղադրիչներ

Թիթեղի պատրաստման և մատուցման համակարգեր

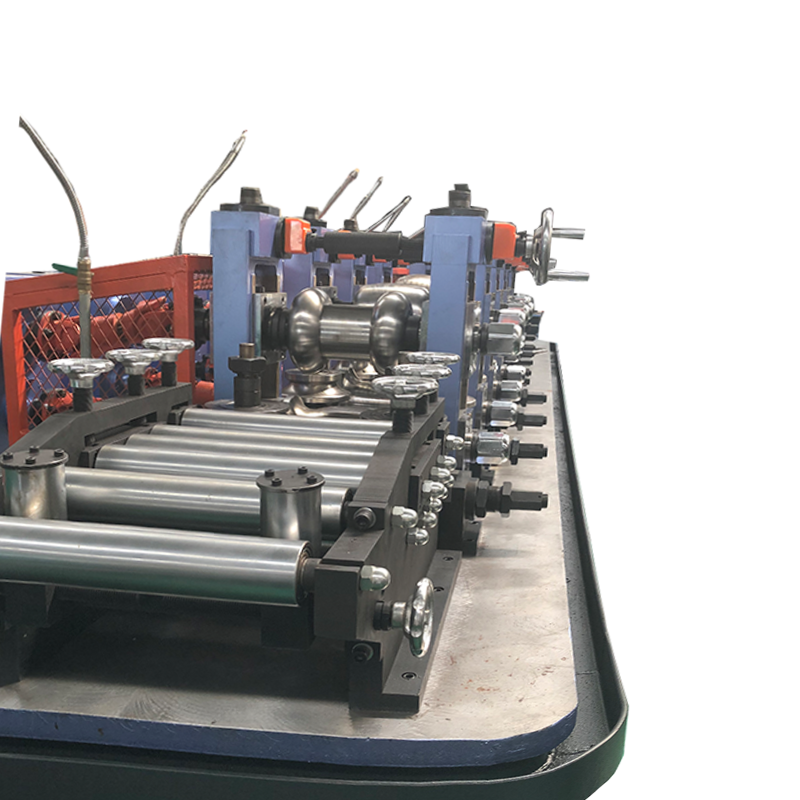

Շարժը սկսվում է պողպատե շերտերի զգոն պատրաստումից, որտեղ HF էլեկտրական հաղորդմամբ փակ խողովակների գործարանները օգտագործում են բարդ անմիջական և հարթեցնող սարքավորումներ: Առաջադեմ լարվածության կառավարման համակարգերը ապահովում են նյութի հաստատուն մատուցումը, իսկ ճշգրիտ ուղղումը վերացնում է շերտի դեֆորմացիան, որը կարող է վնասել վերջնական արտադրանքի որակը:

Ժամանակակից միլները սարքավորված են ավտոմատացված շերտի եզրի պայմանավորման համակարգերով, որոնք նախապատրաստում են նյութի եզրերը՝ ապահովելով օպտիմալ լցում: Այս կարևորագույն քայլը ներառում է համակարգչով ղեկավարվող մշակման կամ սափրման գործողություններ, որոնք ստեղծում են բարձր հաճախականությամբ լցման համար իդեալական երկրաչափություն, ինչը զգալիորեն նվազեցնում է լցման սխալների ռիսկը:

Ձևավորման և չափսի սարքավորումներ

HF-ով լցված խողովակների միլների ձևավորման հատվածը մեխանիկական ինժեներիայի մի քանդակ է: Ընթացիկ ձևավորող կայանները սկզբնական հարթ շերտը մեկ շարք հստակ կարգավորված ռոլիկների միջոցով աստիճանաբար ձևավորում են խողովականման ձև: Յուրաքանչյուր ձևավորող կայան ճշգրիտ նախագծված է՝ պահպանելով նյութի հատկությունները՝ միաժամանակ ձեռք բերելով ցանկալի խողովակի երկրաչափություն:

Գերակշռող սերվո-համակարգերը վերահսկում են ձևավորման գործընթացը՝ թույլ տալով իրական ժամանակում կատարել կարգավորումներ՝ հաշվի առնելով տարբեր խողովակների չափերն ու նյութերը: Այս ճկունությունը թույլ է տալիս արտադրողներին արդյունավետ կերպով փոխանցել արտադրանքի տեխնիկական պահանջներին, առավելացնելով արտադրության բազմազանությունն ու արտադրողականությունը:

Տեխնոլոգիա բարձր հաճախությամբ 悍ցման

Էներգիայի արտադրման և կառավարման համակարգեր

Բարձր հաճախականությամբ էլեկտրական միացման խողովակների գործարանների սրտում գտնվում է բարդացված բարձր հաճախականությամբ սեղմման համակարգը: Ժամանակակից տեղադրումները օգտագործում են պինդ մարմնի գեներատորներ՝ աշխատելով 150-400 կՀց հաճախականությամբ, որոնք ապահովում են ճշգրիտ էներգիայի կառավարում՝ օպտիմալ միացման ձևավորման համար: Այս առաջադեմ էներգային համակարգերը ապահովում են ջերմության համաչափ բաշխում միացման կարի երկայնքով՝ ապրանքի որակը պահպանելու համար:

Թվային կառավարման համակարգերը իրական ժամանակում հսկում և կարգավորում են միացման պարամետրերը՝ հաշվի առնելով նյութի հատկությունների և շահագործման պայմանների փոփոխությունները: Այս կառավարման մակարդակը օգնում է հասնել գերազանց միացման ամբողջականության՝ նվազագույնի հասցնելով էներգասպառումը և կրճատելով շահագործման ծախսերը:

Միացման գոտու կառավարում

Բարձր հաճախականությամբ էլեկտրական միացման խողովակների գործարաններում միացման գոտին ներառում է բարդացված սառեցման համակարգեր և ճնշման կառավարման մեխանիզմներ: Միացումից անմիջապես հետո սառեցումը օգնում է օպտիմալացնել միացված տարածքի մետաղագիտական կառուցվածքը, իսկ ճշգրիտ ճնշման կառավարումը ապահովում է տաքացված եզրերի ճիշտ կովկային միացում:

Գագաթնակետի մարիչները օգտագործում են բազմաթիվ սառեցման գոտիներ՝ անկախ ջերմաստիճանի կառավարմամբ, ինչը հնարավորություն է տալիս օպտիմալացնել սառեցման արագությունը՝ տարբեր մատերիալների և պատերի հաստության դեպքում: Այս մոտեցումը հանգեցնում է հաստատական բարձրորակ կապակցումների՝ հիանալի մեխանիկական հատկություններով:

Որակի վերահսկողություն և ստուգման համակարգեր

Առցանց հսկման տեխնոլոգիաներ

Ժամանակակից HF-ով կապակցված խողովակների մարիչները ամբողջ արտադրական գծով ինտեգրում են համապարփակ որակի վերահսկողության համակարգեր: Գագաթնակետի սենսորները անընդհատ հսկում են կարևոր պարամետրեր, ինչպիսիք են շերտի դիրքը, ջերմաստիճանի բաշխումը և կապակցման երկրաչափությունը: Իրական ժամանակում տվյալների վերլուծությունը հնարավորություն է տալիս անմիջապես հայտնաբերել և ուղղել հնարավոր որակի խնդիրները:

Ավտոմատացված տեսողական համակարգերը ստուգում են մակերեսի որակը և չափագիտական ճշգրտությունը, իսկ էլեկտրամագնիսական փորձարկման սարքավորումները գնահատում են կապակցման ամբողջականությունը՝ արտադրությունը չընդհատելով: Այս անընդհատ հսկման մոտեցումը զգալիորեն կրճատում է թերությունների քանակը և ապահովում է հաստատական արտադրանքի որակ:

Վերջնական փորձարկում և սերտիֆիկացում

HF էլեկտրական միացման խողովակների գործարաններում վերջնական ստուգման փուլը միավորում է բազմաթիվ փորձարկման տեխնոլոգիաներ՝ ապրանքի համապատասխանությունն ապահովելու համար միջազգային ստանդարտներին: Հիդրավլիկական փորձարկումը, ուլտրաձայնային զննումը և մեխանիկական փորձարկումները տալիս են խողովակի ամբողջականության և շահագործման հատկանիշների համապարփակ հաստատում:

Թվային փաստաթղթերի համակարգերը ավտոմատ ստեղծում են մանրամասն որակի վկայականներ՝ պահպանելով յուրաքանչյուր խողովակի հատվածի արտադրության պարամետրերի և փորձարկման արդյունքների լրիվ հետևողականությունը: Այս համապարփակ որակի ապահովման մոտեցումը համապատասխանում է ժամանակակից արդյունաբերական կիրառությունների խիստ պահանջներին:

Ապագայի նորարարություններ եւ միտումներ

Կարևորագույն UFACTURING Integration

HF կապված խողովակների գործարանների ապագան կապված է արդյունաբերության 4.0-ի տեխնոլոգիաների ինտեգրման հետ: Առաջադեմ գործարանները ավելի շատ են օգտագործում արհեստական ինտելեկտ և մեքենայական ուսուցման ալգորիթմներ՝ արտադրության պարամետրերը օպտիմալացնելու և սպասարկման անհրաժեշտությունները կանխատեսելու համար: Այս ինտելեկտուալ համակարգերը վերլուծում են շահագործման մեծ ծավալով տվյալներ՝ հայտնաբերելու արդյունավետությունը բարելավելու և որակը բարձրացնելու հնարավորություններ:

Ինտերնետ օբյեկտների (IoT) սենսորները, որոնք տեղադրված են արտադրական գծի ընթացքում, հնարավորություն են տալիս հսկողություն և կառավարում իրականացնելու, իսկ թվային երկվորյակները տրամադրում են վիրտուալ մոդելավորում՝ գործընթացների օպտիմալացման և օպերատորների վերապատրաստման համար: Այս տեխնոլոգիական ձեռքբերումները փոխակերպում են ժամանակակից խողովակների արտադրության հնարավորություններն ու արդյունավետությունը:

Համարժեքություն և էներգիայի արդյունավետություն

Շրջակա միջավայրի նկատմամբ հաշվի առնելը խթանում է ՆՀ կապակցված խողովակների գործարաններում նորարարությունների մշակումը, որտեղ արտադրողները կենտրոնանում են էներգասպառման կրճատման և շրջակա միջավայրի վրա ազդեցությունը նվազագույնի հասցնելու վրա: Նոր լցման տեխնոլոգիաները ապահովում են բարելավված էներգաօգտագործման արդյունավետություն, իսկ առաջադեմ նյութերի կառավարման համակարգերը նվազեցնում են թափոնները և օպտիմալացնում են ռեսուրսների օգտագործումը:

Վերականգնողական համակարգերը վերականգնում են էներգիան արտադրական գործընթացներից, իսկ ինտելեկտուալ էլեկտրամատակարարման կառավարման համակարգերը օպտիմալացնում են էլեկտրաէներգիայի սպառումը ամբողջ սարքավորման ընթացքում: Այս կայունության նախաձեռնությունները ոչ միայն նվազեցնում են շահագործման ծախսերը, այլ նաև համապատասխանում են գլոբալ շրջակա միջավայրի պաշտպանության նպատակներին:

Հաճախ տրվող հարցեր

Ի՞նչ առավելություններ ունեն ՆՀ-ով կապակցված խողովակները անընդհատ պոկերի նկատմամբ:

ՆՀ-ով կապակցված խողովակները ունեն մի շարք առավելություններ, այնպիսիք ինչպիսին են ծախսարդյունավետությունը, հաստության հաստատուն պատերը և գերազանց մակերեսային վերջնամշակումը: Բարձր հաճախականությամբ լցման գործընթացը ապահովում է վստահելի լցման որակ՝ պահպանելով արտադրողականությունը, ինչը այդ խողովակները դարձնում է իդեալական շատ արդյունաբերական կիրառությունների համար:

Ինչպե՞ս է բարձր հաճախականությամբ լցվածքը բարելավում խողովակի որակը

Բարձր հաճախականությամբ լցվածքը ստեղծում է ճշգրիտ, տեղային տաքացման գոտի, որն ապահովում է գերազանց լցվածքի ամբողջականություն: Այս գործընթացը նվազագույնի է հասցնում ջերմային ազդեցության գոտիները, պահպանում է նյութի հատկությունները և արտադրության ընթացքում ապահովում է հաստատուն լցվածքի որակ:

Ինչ դեր է խաղում ավտոմատացումը ժամանակակից խողովակաշարային գործարաններում

HF լցվածքով խողովակների գործարաններում ավտոմատացումը բարձրացնում է արտադրողականությունը, ապահովում է հաստատուն որակ և նվազեցնում է մարդկային սխալները: Գագաթնակետային կառավարման համակարգերը վերահսկում են նյութերի փոխադրումից սկսած մինչև լցվածքի պարամետրերը, իսկ ավտոմատացված ստուգման համակարգերը արտադրության ընթացքում անընդհատ վերահսկում են որակը: