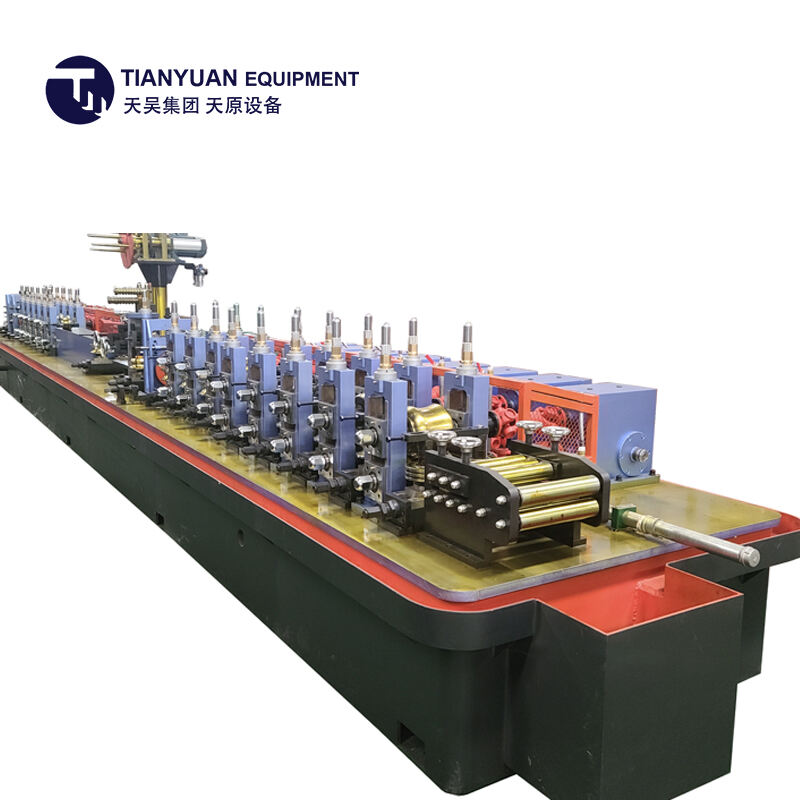

mesin pembuat pipa baja karbon yang disesuaikan

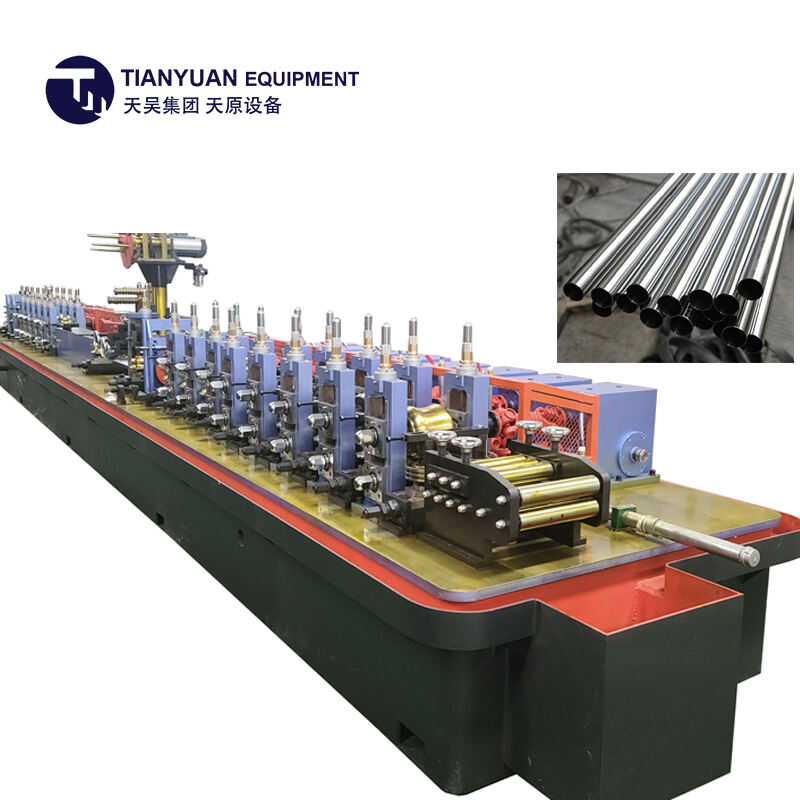

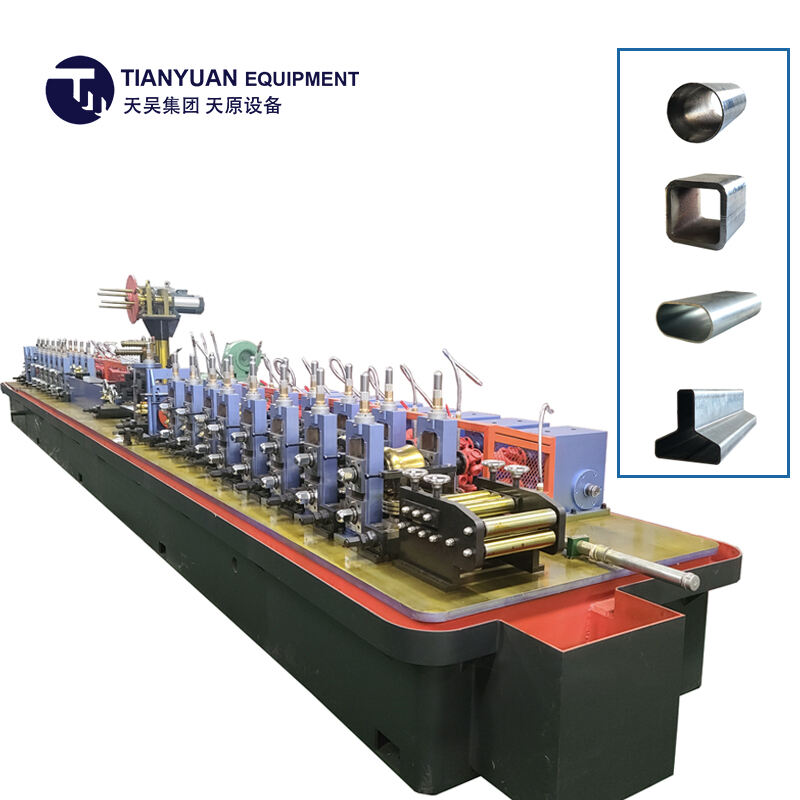

Mesin pembuat pipa baja karbon yang disesuaikan mewakili terobosan dalam teknologi manufaktur modern, dirancang untuk memberikan pipa yang diproduksi dengan presisi untuk berbagai aplikasi industri. Peralatan canggih ini menggabungkan konstruksi yang kokoh dengan otomatisasi terkini untuk menghasilkan pipa baja karbon berkualitas tinggi dengan dimensi dan spesifikasi yang bervariasi. Mesin ini mencakup sistem kontrol yang canggih yang memantau dan menyesuaikan parameter produksi secara real-time, memastikan kualitas yang konsisten sepanjang proses manufaktur. Fungsi utamanya meliputi pemberian material, pembentukan, pengelasan, penyesuaian ukuran, dan pemotongan, semuanya diintegrasikan ke dalam jalur produksi yang mulus. Teknologi ini memiliki kemampuan pengelasan maju dengan sistem pengelasan induksi frekuensi tinggi, mekanisme kontrol dimensi yang tepat, dan protokol inspeksi kualitas otomatis. Mesin ini dapat menangani berbagai jenis baja dan ketebalan dinding, membuatnya fleksibel untuk kebutuhan industri yang beragam. Dengan kecepatan produksi hingga 80 meter per menit, mesin ini secara signifikan meningkatkan efisiensi manufaktur sambil mempertahankan standar kualitas yang ketat. Desain adaptif mesin memungkinkan pergantian cepat antara spesifikasi pipa yang berbeda, meminimalkan waktu henti dan memaksimalkan produktivitas. Ini sangat cocok untuk memproduksi pipa yang digunakan dalam konstruksi, transportasi minyak dan gas, sistem penyediaan air, dan aplikasi struktural.