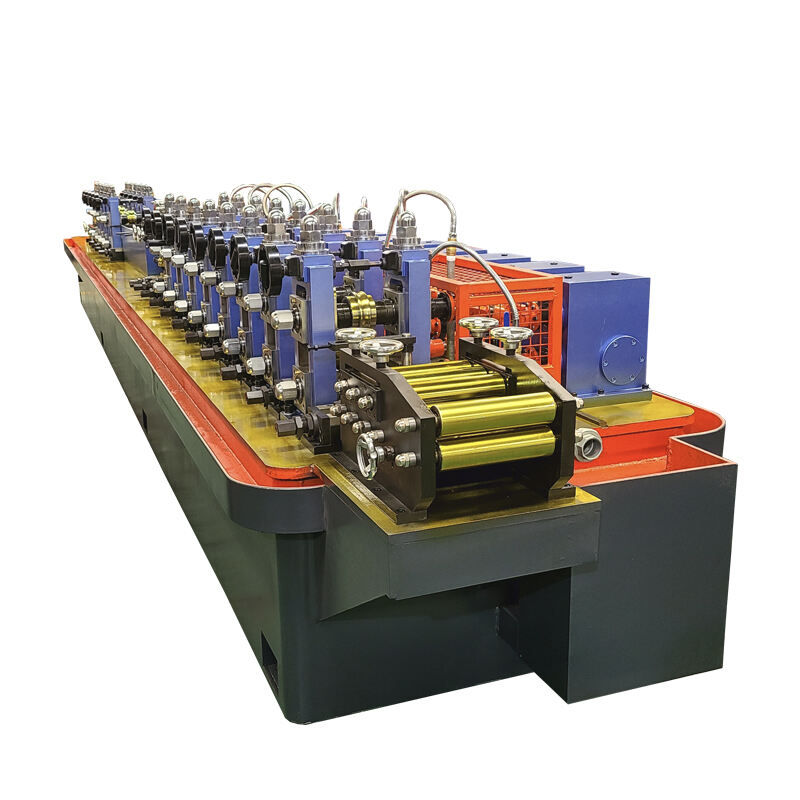

mesin pembentuk pipa yang stabil

Mesin pembentuk pipa yang stabil mewakili terobosan dalam teknologi manufaktur industri modern, dirancang untuk menghasilkan pipa berkualitas tinggi dengan konsistensi dan presisi luar biasa. Peralatan canggih ini menggunakan teknologi roll forming terkini untuk mentransformasikan strip logam datar menjadi pipa silinder sempurna melalui proses sistematis berlangkah-langkah. Mesin ini dilengkapi dengan sistem kontrol canggih yang mempertahankan akurasi dimensi yang tepat selama proses pembentukan, memastikan setiap pipa memenuhi spesifikasi yang tepat. Konstruksi kokohnya mencakup gulungan pembentuk baja keras, sistem panduan yang diproduksi secara presisi, dan kemampuan pengelasan canggih yang bekerja dengan sinkronisasi sempurna. Mesin ini dapat menangani berbagai bahan, termasuk baja karbon, baja tahan karat, dan aluminium, dengan rentang ketebalan biasanya dari 0,5mm hingga 6mm. Beroperasi pada kecepatan hingga 120 meter per menit, ia menyertakan fitur otomatis seperti kontrol panjang, sistem pemotongan sesuai panjang, dan sensor pemantauan kualitas. Mesin pembentuk pipa yang stabil sangat berharga di industri seperti konstruksi, manufaktur otomotif, produksi furnitur, dan pengembangan infrastruktur, di mana kualitas pipa yang konsisten sangat penting. Keterampilannya memungkinkan produksi pipa bulat maupun pipa berbentuk khusus, dengan rentang diameter dari 20mm hingga 200mm, menjadikannya alat yang tidak tergantikan bagi fasilitas manufaktur modern.