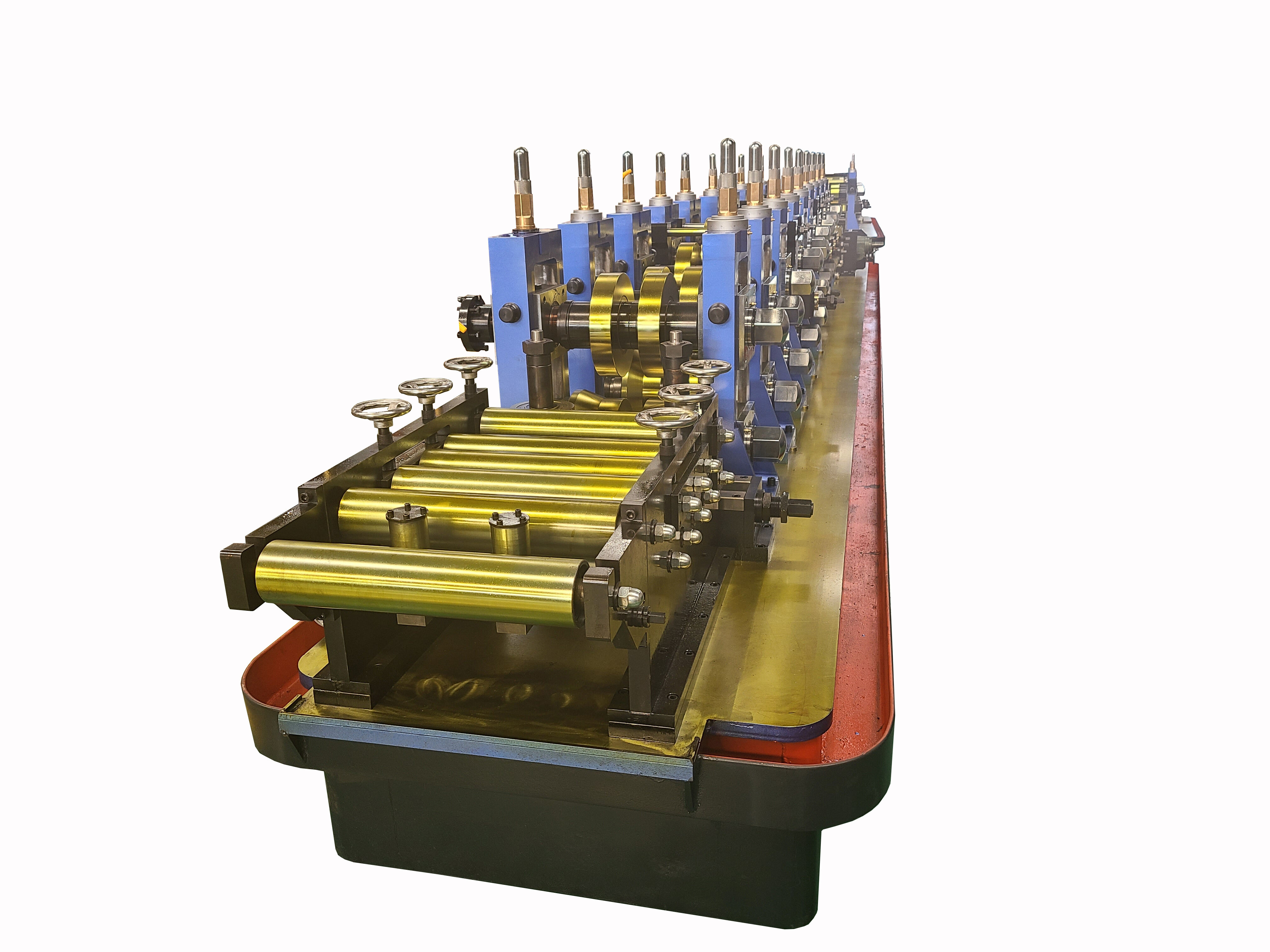

macchina per la formazione di tubi di alta qualità

La macchina per la formazione di tubi ad alta qualità rappresenta un punto di riferimento della tecnologia di produzione moderna, progettata per produrre in modo efficiente tubi precisi e duraturi per varie applicazioni industriali. Questo avanzato equipaggiamento combina una solida ingegneria meccanica con sistemi di controllo all'avanguardia per fornire prodotti tubolari di alta qualità in modo costante. La macchina utilizza un sofisticato processo di roll forming che trasforma strisce metalliche piatte in tubi perfettamente cilindrici attraverso una serie di stazioni di formatura attentamente calibrate. Ogni stazione plasmia progressivamente il materiale, garantendo un diametro uniforme e una qualità di saldatura superiore. Il sistema include meccanismi di alimentazione automatica del materiale, controlli di allineamento precisi e tecnologia di saldatura avanzata che garantisce una produzione senza soluzione di continuità. Con i suoi parametri regolabili, la macchina può adattarsi a diversi diametri di tubo, spessori di parete e specifiche materiali, rendendola versatile per esigenze di produzione diverse. I sistemi integrati di controllo qualità, inclusi il monitoraggio in tempo reale e la rilevazione automatica dei difetti, garantiscono che ogni tubo rispetti standard industriali rigorosi. Questa macchina si distingue particolarmente per le sue capacità operative ad alta velocità mentre mantiene un'eccezionale precisione nel controllo dimensionale e nella qualità della finitura superficiale.