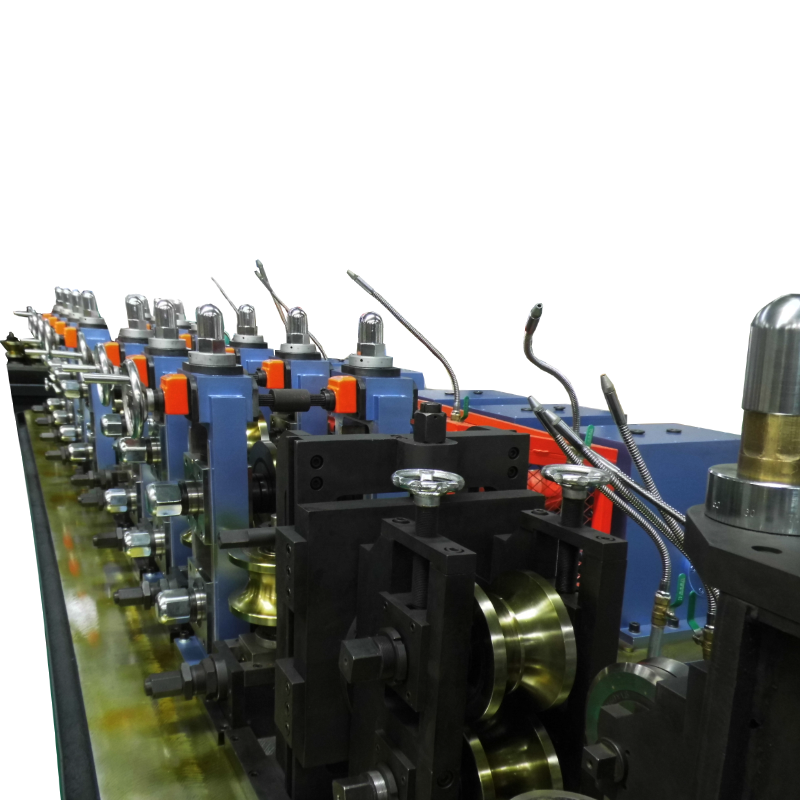

macchina per la fabbricazione di tubi gi stabile

La macchina per la produzione di tubi GI stabile rappresenta un significativo progresso nella tecnologia di produzione dei tubi, offrendo una soluzione completa per la fabbricazione di tubi in acciaio galvanizzato di alta qualità. Questo sofisticato equipaggiamento integra numerosi processi, tra cui srotolamento, formatura, saldatura, dimensionamento e taglio, tutti all'interno di una singola linea di produzione. La macchina utilizza sistemi avanzati di controllo della frequenza e tecnologia di saldatura precisa per garantire una formatura costante del tubo e una qualità superiore della saldatura. La sua costruzione robusta presenta un telaio pesante che minimizza le vibrazioni, contribuendo a migliorare la stabilità operativa e l'uniformità del prodotto. La macchina può elaborare varie specifiche di tubi, gestendo tipicamente diametri da 12mm a 76mm con spessori di parete compresi tra 0.5mm e 3mm. La linea di produzione incorpora controlli automatizzati e sistemi di monitoraggio in tempo reale, consentendo agli operatori di mantenere un controllo preciso sui parametri critici come la velocità di formatura, la temperatura di saldatura e la lunghezza di taglio. Caratteristiche notevoli includono stazioni di formatura regolabili, capacità di saldatura ad alta frequenza e un sistema di raffreddamento avanzato che garantisce una gestione ottimale della temperatura durante il processo di produzione. Il design della macchina priorizza efficienza e affidabilità, rendendola adatta sia per produzioni continue che per frequenti cambiamenti di specifiche.