მანგანის რუბლის წარმოების მაशინა

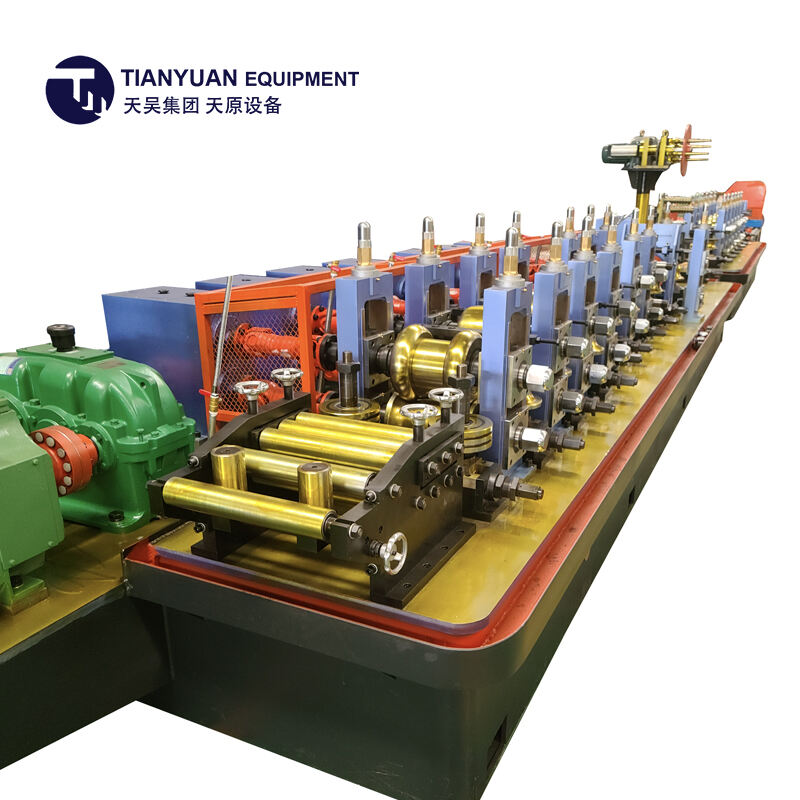

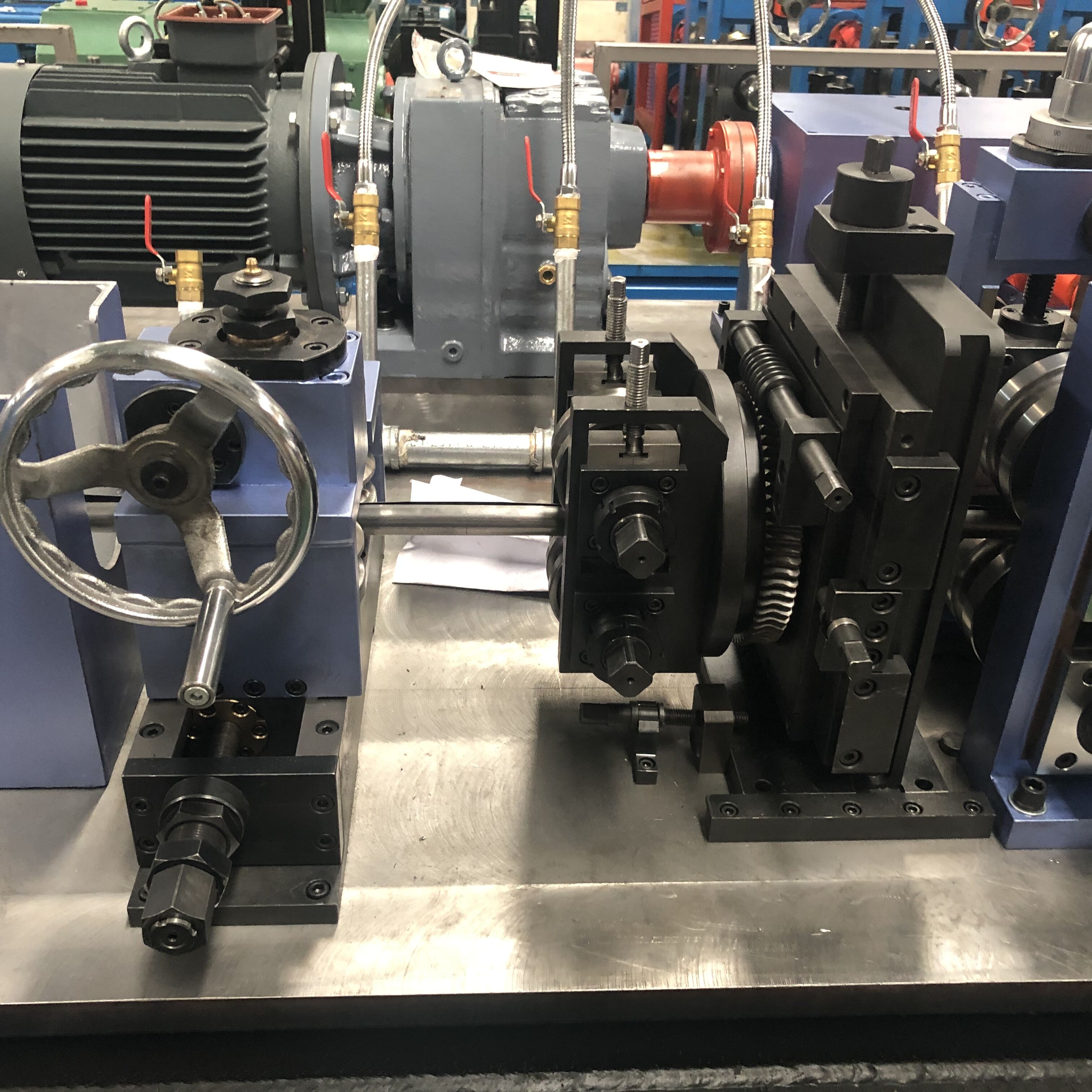

MS მართივის წარმოების მანქანა წარმოადგენს ინნოვაციულ ამოხსნას სამოდერნო ინდუსტრიულ მართივის წარმოებაში. ეს სოფისტიკირებული მანქანა გარდაქმნის მიღების მართივს (MS) მაღალ ხარისხის მართივებად ზუსტ მექანიკური პროცესის მეშვეობით. მანქანაში ჩანაწერილია განვითარებული როლირების ტექნოლოგია, ავტომატური სველის სისტემები და ზუსტი განზომილების კონტროლის მექანიზმები, რათა დაუკავშირდეს პროდუქტის ხარისხი. სისტემის ბაზის წყაროში მდებარეობს დეკოილინგის ერთეული, რომელიც დარწმუნებულია მართივის ბენდების მოწოდებაში ფორმირების საფარიშებში, სადაც როლები მაღალი სიჩქარით ფორმირებს მასალას ტუბურ ფორმაში. მანქანის მაღალი სიხშირის სველის სისტემა შექმნის ძლიერ და ერთforma სველებს, ხოლო განზომილების სექცია დაუკავშირდეს ზუსტი განზომილების სპეციფიკაციები. ხარისხის კონტროლის სისტემები, რომლებიც ჩამოვიდებით აკონტროლებენ ულტრასაouncალურ ტესტებს და ვიზუალურ შემოწმებას, ინტეგრირებულია მთელი პროდუქციის ხაზის განმავლობაში. მანქანა შეიძლება წარმოებინა მართივები 20 მმ-დან 165 მმ-მდე დიამეტრში, საგვრდელი სი厚厚ით 1.2 მმ-დან 6 მმ-მდე. განვითარებული კონტროლის სისტემები შესაძლებლობას აძლევენ სწრაფ გამოსავალების პარამეტრების გამოსაცდელად, რათა წარმოებლები ეფექტურად გადადგინონ სხვადასხვა მართივის სპეციფიკაციებს. მანქანის ვერსატილობა ხდის მას შესაბამისად გამოყენებად საშენო კონსტრუქციებში, მебლის წარმოებაში, ავტომობილურ კომპონენტებში და განსხვავებულ ინდუსტრიულ აპლიკაციებში. პროდუქციის სიჩქარე შეიძლება მიიღოს მაქსიმუმ 80 მეტრი წუთში, რაც ასახავს მანქანის მაღალ ეფექტიურობას და ხარისხის კონტროლს.