Manufacturing industries worldwide depend on robust and efficient equipment to maintain consistent production quality, and few machines exemplify reliability like the Carbon Steel Pipe Making Machine. These sophisticated manufacturing systems have become the backbone of steel fabrication operations, delivering precise results while maintaining exceptional durability under demanding industrial conditions. The engineering excellence behind these machines stems from decades of technological advancement and continuous refinement of manufacturing processes.

The reliability of modern pipe manufacturing equipment extends beyond simple mechanical construction, encompassing advanced control systems, precision engineering, and materials science innovations. Understanding the fundamental principles that make these machines so dependable helps manufacturers make informed decisions about equipment investments and operational strategies. The consistent performance characteristics of a Carbon Steel Pipe Making Machine directly impact production efficiency, product quality, and overall profitability in steel processing operations.

Engineering Excellence in Carbon Steel Pipe Manufacturing

Advanced Material Selection and Construction

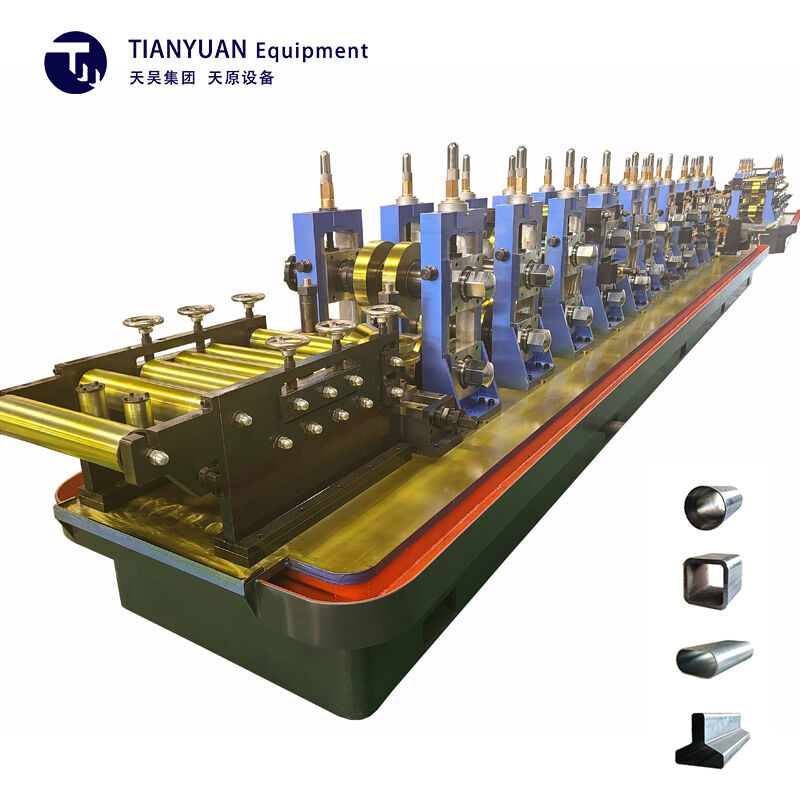

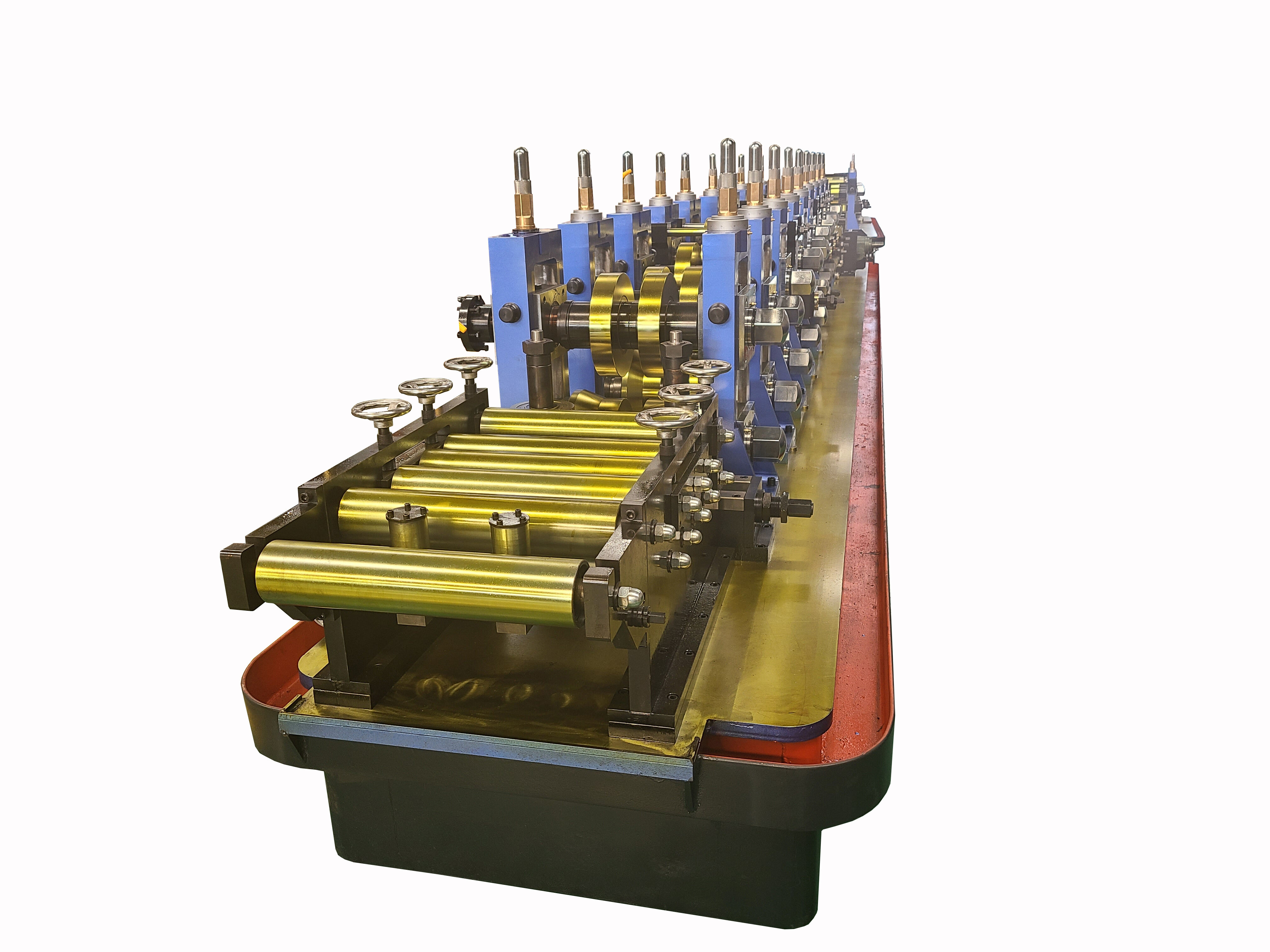

The foundation of reliability in any Carbon Steel Pipe Making Machine begins with superior material selection and construction methodologies. Manufacturers utilize high-grade alloy steels and precision-forged components to create machine frames and operational elements that withstand extreme pressures and continuous operation cycles. These materials undergo rigorous testing procedures to ensure they meet or exceed industry standards for durability and performance consistency.

Critical components such as forming rolls, drive systems, and structural frameworks are manufactured using advanced metallurgical processes that enhance grain structure and eliminate potential failure points. The integration of wear-resistant coatings and surface treatments further extends component lifespan while maintaining dimensional accuracy throughout extended production runs. This attention to material science translates directly into reduced maintenance requirements and increased operational uptime.

Quality control measures during the manufacturing process ensure that each Carbon Steel Pipe Making Machine meets stringent specifications for mechanical properties, dimensional tolerances, and surface finish requirements. Advanced inspection techniques, including non-destructive testing methods, verify the integrity of critical components before assembly and final testing procedures.

Precision Engineering and Manufacturing Tolerances

Modern pipe making equipment demonstrates exceptional reliability through precision engineering practices that maintain tight manufacturing tolerances across all operational components. CNC machining centers and advanced manufacturing technologies enable the production of components with micron-level accuracy, ensuring proper fit and function throughout the machine's operational lifecycle. This precision extends to forming rolls, guide systems, and drive mechanisms that directly influence product quality.

The implementation of advanced measurement and calibration systems during manufacturing ensures that each Carbon Steel Pipe Making Machine delivers consistent performance characteristics. Sophisticated quality assurance protocols verify dimensional accuracy, surface finish quality, and mechanical properties before equipment leaves the manufacturing facility. These rigorous standards contribute significantly to the long-term reliability and performance consistency that operators expect.

Assembly procedures follow detailed specifications and utilize torque-controlled fastening systems to ensure proper component alignment and stress distribution. This methodical approach to construction minimizes the potential for premature wear or mechanical failures that could compromise operational reliability.

Advanced Control Systems and Automation

Integrated Process Control Technology

Contemporary Carbon Steel Pipe Making Machine designs incorporate sophisticated control systems that monitor and adjust operational parameters in real-time, ensuring consistent product quality while protecting equipment from potentially damaging operating conditions. These systems utilize advanced sensors, feedback loops, and automated adjustment mechanisms to maintain optimal forming pressures, speeds, and dimensional controls throughout the production process.

Programmable logic controllers and human-machine interfaces provide operators with comprehensive monitoring capabilities and predictive maintenance alerts that help prevent equipment failures before they occur. The integration of data logging and analysis capabilities enables manufacturers to identify trends and optimize operational parameters for maximum efficiency and reliability.

Safety systems integrated into modern control architectures automatically respond to abnormal operating conditions by implementing protective measures that safeguard both equipment and personnel. Emergency stop systems, overload protection, and automatic shutdown sequences prevent damage that could compromise the long-term reliability of the Carbon Steel Pipe Making Machine.

Predictive Maintenance and Monitoring Systems

Advanced monitoring systems continuously track key performance indicators and equipment health parameters to enable predictive maintenance strategies that maximize uptime and extend equipment lifespan. Vibration analysis, temperature monitoring, and lubrication system diagnostics provide early warning signs of potential issues before they develop into costly failures.

Data collection and analysis capabilities built into modern Carbon Steel Pipe Making Machine designs enable operators to establish baseline performance characteristics and identify deviations that may indicate developing problems. This proactive approach to maintenance scheduling reduces unexpected downtime and extends the operational life of critical components.

Remote monitoring capabilities allow technical support teams to diagnose issues and provide assistance without requiring on-site visits, reducing response times and minimizing production interruptions. These connectivity features enhance the overall reliability of pipe manufacturing operations by ensuring rapid access to technical expertise when needed.

Operational Efficiency and Production Consistency

Optimized Manufacturing Processes

The reliability of a Carbon Steel Pipe Making Machine directly correlates with its ability to maintain consistent production parameters across extended operating periods. Advanced forming technologies and precision control systems ensure that each pipe meets exact specifications for diameter, wall thickness, and straightness tolerances. This consistency reduces waste, minimizes rework requirements, and maintains customer satisfaction through reliable product quality.

Automated feeding systems and material handling components minimize manual intervention requirements while ensuring consistent material presentation to forming operations. These systems incorporate quality control measures that detect and reject substandard raw materials before they can affect final product quality or cause equipment damage.

Process optimization features continuously adjust operational parameters based on material characteristics, ambient conditions, and production requirements to maintain optimal performance efficiency. These adaptive capabilities help ensure reliable operation across varying production scenarios and material specifications.

Quality Assurance and Testing Integration

Integrated quality assurance systems monitor critical product parameters during the manufacturing process, enabling immediate adjustments when deviations are detected. In-line inspection technologies verify dimensional accuracy, surface quality, and mechanical properties without interrupting production flow, ensuring that every pipe meets specified requirements.

Non-destructive testing capabilities built into modern Carbon Steel Pipe Making Machine designs enable comprehensive quality verification without compromising production efficiency. Ultrasonic testing, eddy current inspection, and visual examination systems provide thorough evaluation of pipe integrity and surface characteristics.

Statistical process control features track production trends and identify potential quality issues before they result in non-conforming products. This proactive approach to quality management supports the reliable operation of pipe manufacturing systems while minimizing waste and rework costs.

Maintenance and Serviceability Features

Accessibility and Component Design

Thoughtful design considerations in modern Carbon Steel Pipe Making Machine construction prioritize maintenance accessibility and component serviceability to minimize downtime during routine maintenance operations. Strategic placement of inspection points, service access panels, and component mounting systems enables maintenance personnel to perform necessary tasks efficiently and safely.

Modular component designs facilitate rapid replacement of wear items and enable preventive maintenance procedures to be completed with minimal production interruption. Quick-disconnect fittings, standardized fasteners, and clear component identification support efficient maintenance practices that contribute to overall system reliability.

Comprehensive maintenance documentation and technical support resources provide operators with detailed procedures and troubleshooting guidance that enable effective problem resolution and preventive maintenance execution. These resources include detailed parts diagrams, maintenance schedules, and recommended spare parts inventories.

Lubrication and Cooling Systems

Sophisticated lubrication systems ensure that critical moving components receive proper lubrication under all operating conditions, extending component life and maintaining smooth operation throughout the production cycle. Centralized lubrication systems with automated monitoring and delivery capabilities eliminate the potential for lubrication-related failures while reducing maintenance labor requirements.

Advanced cooling systems protect sensitive components from excessive heat buildup during high-speed operations, maintaining dimensional stability and preventing thermal damage that could compromise long-term reliability. Temperature monitoring and control systems automatically adjust cooling capacity based on operating conditions and ambient temperature variations.

Filtration and contamination control systems maintain lubricant and coolant quality throughout extended service intervals, protecting critical components from abrasive particles and chemical contamination that could cause premature wear or failure in Carbon Steel Pipe Making Machine operations.

FAQ

What factors contribute most significantly to Carbon Steel Pipe Making Machine reliability?

The primary factors contributing to reliability include high-quality material selection in critical components, precision manufacturing tolerances, advanced control systems with predictive maintenance capabilities, and comprehensive lubrication systems. Additionally, thoughtful design for accessibility and serviceability plays a crucial role in maintaining long-term operational reliability through effective maintenance practices.

How do modern control systems enhance the reliability of pipe manufacturing equipment?

Modern control systems enhance reliability through real-time monitoring of operational parameters, automated adjustment of process variables, and predictive maintenance alerts that prevent equipment failures. These systems also implement safety protocols that protect equipment from damaging operating conditions and provide diagnostic capabilities that enable rapid problem identification and resolution.

What maintenance practices are most important for ensuring continued reliability?

Essential maintenance practices include following manufacturer-recommended service schedules, maintaining proper lubrication of all moving components, regular inspection of wear items, and prompt replacement of components showing signs of deterioration. Additionally, maintaining clean operating environments and proper storage of spare parts contributes significantly to long-term reliability.

How does component quality affect overall machine performance and reliability?

Component quality directly impacts performance through dimensional accuracy, material properties, and manufacturing tolerances that affect fit and function throughout the machine's operational life. High-quality components reduce maintenance requirements, extend service intervals, and maintain consistent performance characteristics that support reliable production operations over many years of service.

Table of Contents

- Engineering Excellence in Carbon Steel Pipe Manufacturing

- Advanced Control Systems and Automation

- Operational Efficiency and Production Consistency

- Maintenance and Serviceability Features

-

FAQ

- What factors contribute most significantly to Carbon Steel Pipe Making Machine reliability?

- How do modern control systems enhance the reliability of pipe manufacturing equipment?

- What maintenance practices are most important for ensuring continued reliability?

- How does component quality affect overall machine performance and reliability?