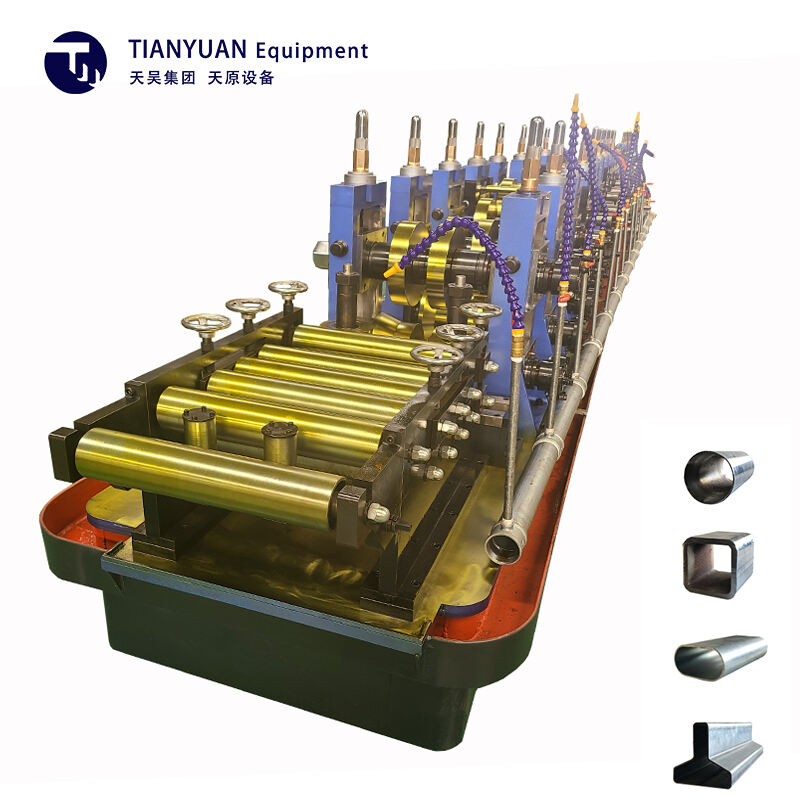

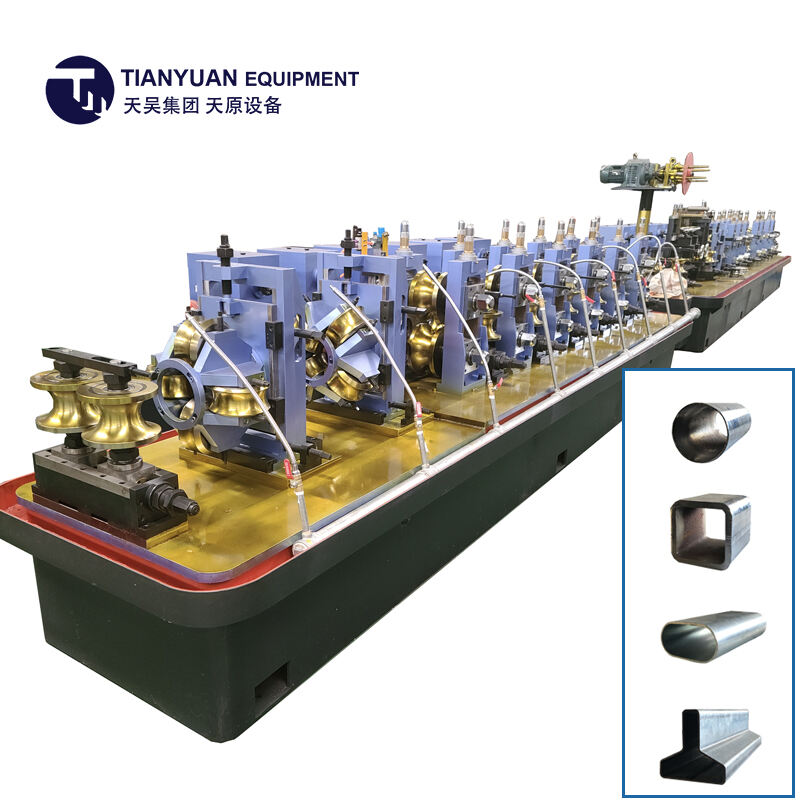

내구성 있는 HF 용접 파이프 밀

내구성이 뛰어난 HF 용접 파이프 밀은 고주파 용접 강관을 매우 정확하고 신뢰성 있게 생산하기 위해 설계된 최신 제조 솔루션입니다. 이 첨단 시스템은 스트립 공급에서 완제품 파이프 처리까지의 여러 생산 단계를 하나의 통합된 생산 라인으로 통합합니다. 밀은 일반적으로 200-400 kHz 범위의 주파수로 작동하는 고주파 인덕션 용접 기술을 사용하여 우수한 용접 품질과 구조적 안정성을 보장합니다. 시스템은 평평한 강철 스트립을 일련의 정밀하게 교정된 롤을 통해 점진적으로 원형 구성을 형성하는 복잡한 성형 스테이션을 통합합니다. 주요 구성 요소에는 자동 스트립 공급 시스템, 성형 섹션, 고급 HF 발전기를 갖춘 용접 스테이션, 사이징 섹션 및 절단 유닛이 포함됩니다. 밀의 능력은 직경 20mm에서 165mm, 두께 1.2mm에서 6mm의 파이프를 생산할 수 있을 정도로 다양한 산업 응용 분야에 적합합니다. 현대적인 자동화 시스템과 실시간 품질 관리 메커니즘으로 강화되어 운영자 개입을 최소화하면서 일관된 생산 품질을 유지합니다. 이 제조 솔루션은 건설, 자동차, 가구 및 구조물 등 고품질 용접 파이프가 필요한 산업에서 특히 가치가 있습니다.