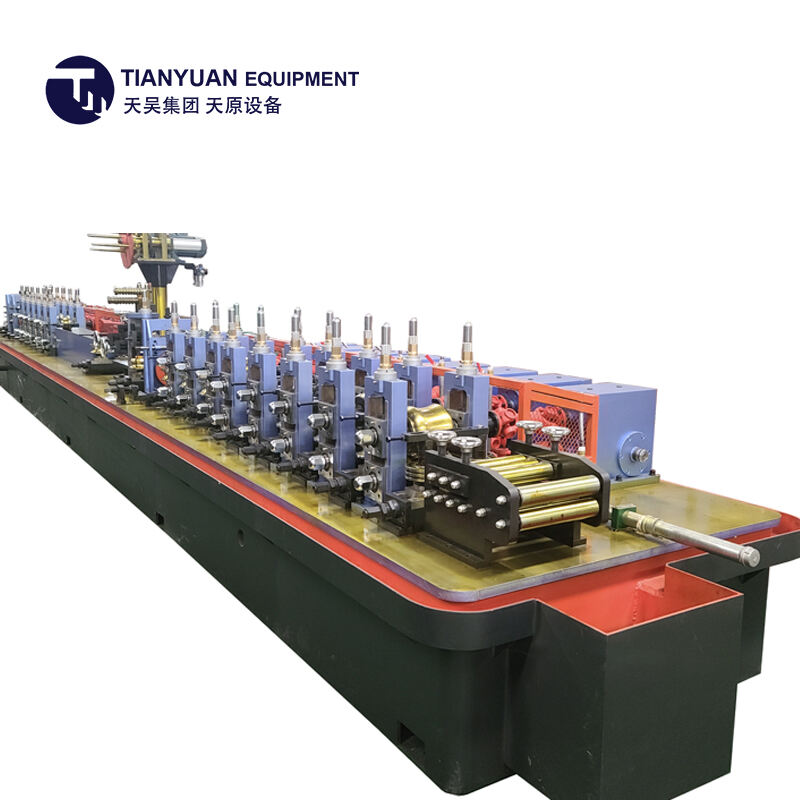

효율적인 탄소강 파이프 제작 기계

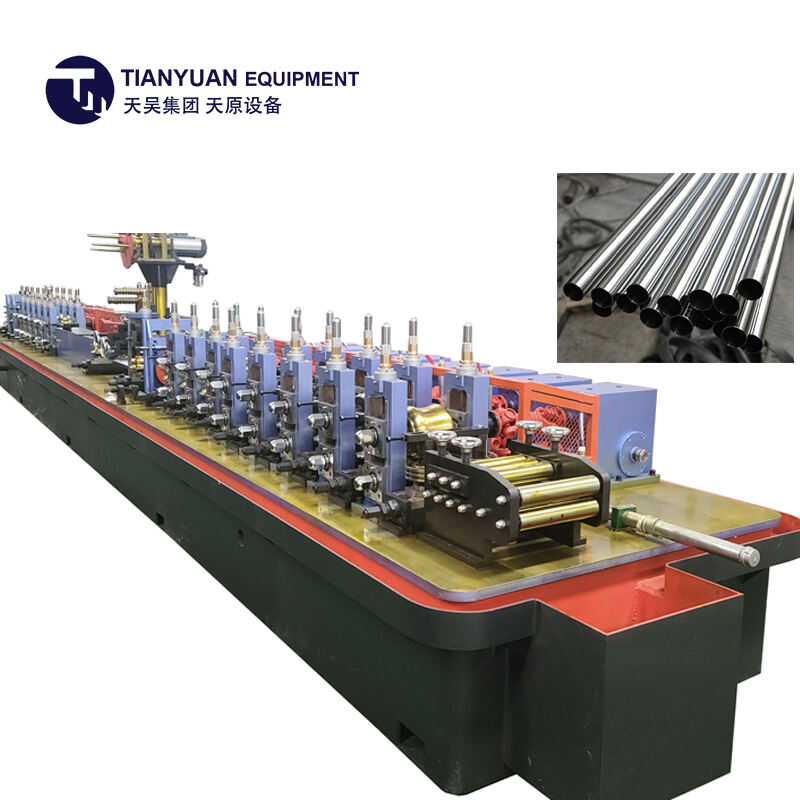

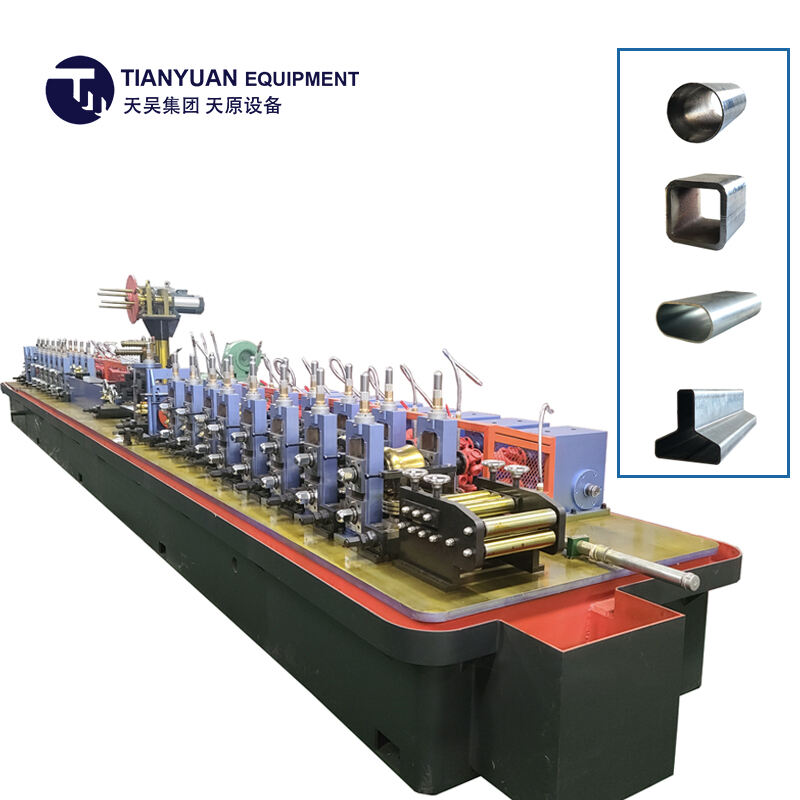

효율적인 탄소강 파이프 제작 기계는 정확성과 일관성을 가지고 고품질의 탄소강 파이프를 생산하기 위해 설계된 최신 제조 솔루션을 나타냅니다. 이 첨단 기계는 재료 공급, 성형, 용접, 사이징 및 절단 과정을 포함한 여러 생산 단계를 하나의 통합 시스템 내에서 수행합니다. 이 기계는 균일한 벽 두께와 우수한 구조적 안정성을 보장하는 고급 성형 기술을 사용합니다. 자동 제어 시스템은 전체 생산 과정에서 정확한 치수 정밀도를 유지하며, 고주파 용접 기술은 견고하고 신뢰할 수 있는 봉합 접합부를 보장합니다. 이 기계는 다양한 파이프 사양을 처리할 수 있으며, 일반적으로 직경 20mm에서 219mm, 벽 두께 1.2mm에서 6mm 범위의 파이프를 생산할 수 있습니다. 산업용 부품으로 구성된 시스템은 온도, 압력, 용접 품질 등을 지속적으로 평가하는 고도의 모니터링 시스템을 특징으로 합니다. 이 기계의 유연성은 빠른 사양 변경을 가능하게 하여 대량 생산뿐만 아니라 맞춤형 제조 요구사항에도 이상적입니다. 강화된 효율성 메커니즘은 일관된 출력 품질을 유지하면서 최소한의 재료 낭비와 에너지 소비를 실현합니다. 이 장비는 건설, 석유 및 가스 운송, 기계공학, 구조적 응용 분야 등에서 고품질의 탄소강 파이프가 필수적인 구성 요소인 산업에서 광범위하게 적용됩니다.