fornitores machinae fabricandi tubos gi

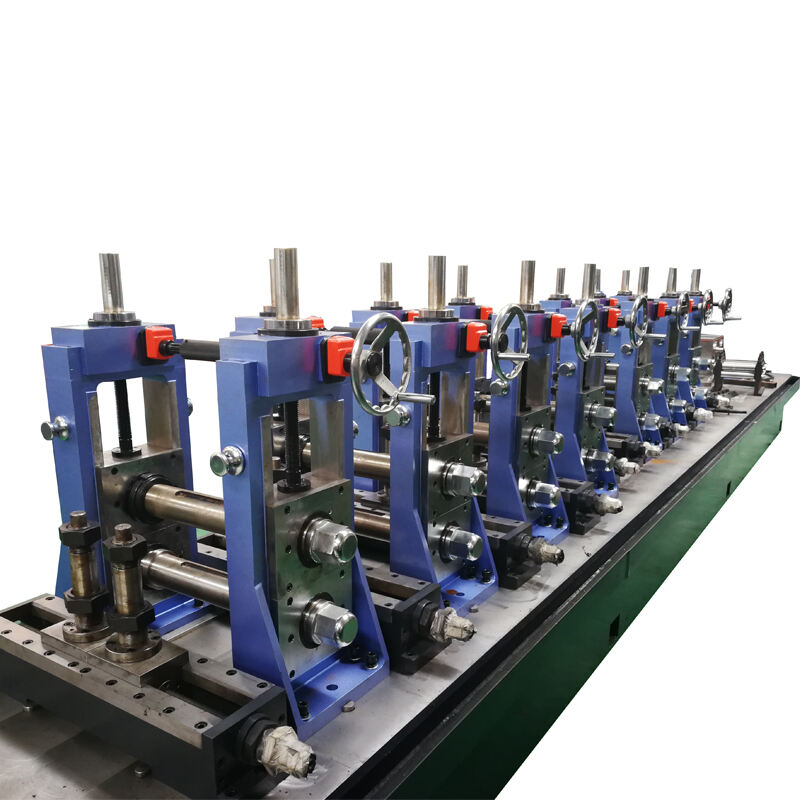

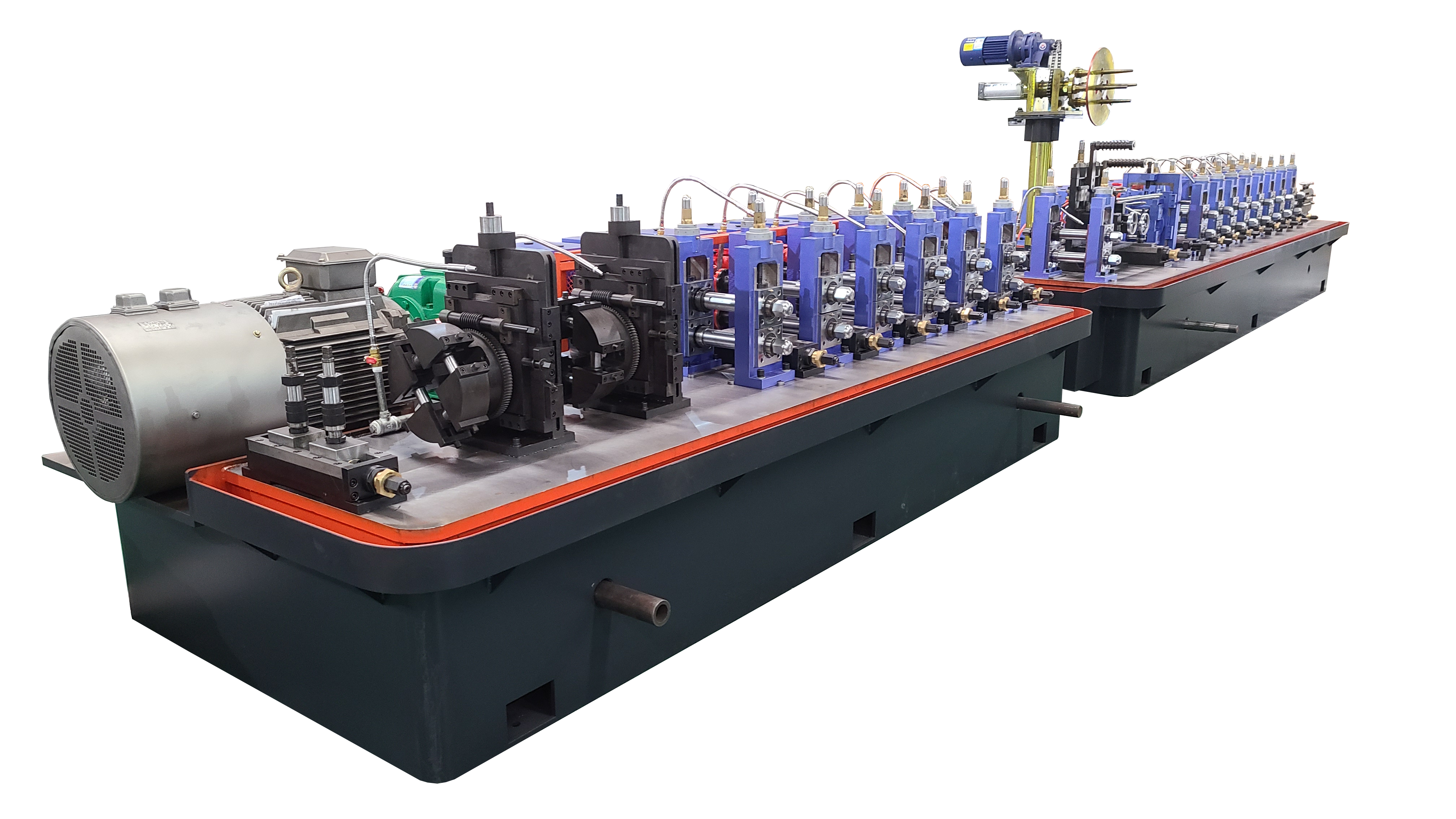

Fornitores machinarum fabricandarum tuborum GI exercent partem crucialem in industria manufactoria praebendo apparatus necessarios ad producendum altae qualitatis tubos ferri galvanizati. Hi fornitores offerunt solutiones integrales quae comprehendunt machinas recentissimi temporis capaces fabricandorum tuborum cum dimensionibus exactis et finitione superiori. Machinae solito praebent systema controlis avancii, processus soderatorii automatisati, et unitates galvanizationis efficientes. Possunt producere tubos a parvis diametris pro installationibus domesticis usque ad applicationes industriales magnas. Machinae modernae fabricandarum tuborum GI includunt technologiam soderationis altae frequentiae, systemata formandi exacta, et mechanica qualitatis controlis quae consistentiam qualitatis productus securent. Hi fornitores saepe praebent lineas productionis integrales quae comprehendunt systemata explicandi, sectiones formandi, unitates soderatorias, stationes dimensionis, et mechanicas secandi. Machinae sunt descriptae ad tractandas varias crassitudines materialium et possunt attingere velocitates productionis usque ad 80 metra per minutum, dependens a modello et specificis. Praeterea, multi fornitores offrant optiones customizationis ad satisfaciendum requisita manufactoria specialia, includentes systemata tegumenti specialia et solutiones imballatorii automatisati.