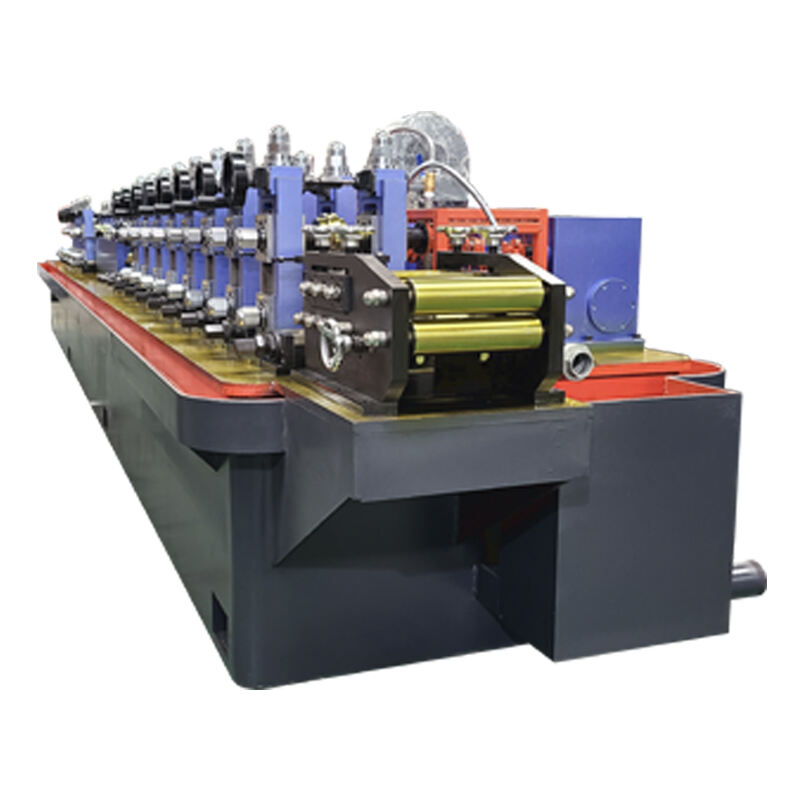

Fabricatio industrialis moderna multum innititur instrumentis efficacibus et praecisis ad crescentes necessitates qualitatis tuborum in variis sectoribus satisfaciendas. Industriae quae a constructione et automobilis usque ad petrolei et gasi patet, solutiones tubulares sine iunctura, durabiles, requirunt quae conditionibus extremis resistere possint dum integritatem structuralem servant. Evolutio technologiae fabricationis effecit ut instrumenta docta materias primas in productos perfectos transforment cum mirabili praecisione et constantia.

Aucta Efficiencia et Celeritas Productionis

Processus fabricandi automatice

Implementatio machinae formatae tuborum processus productionis revocat, removendo angustias laboris manualis et significanter minuendo tempora cyclorum. Haec perita systemata continuo operantur humanique interventus minimi, ut fabricatores altiores proventus taxas consequi possint, aequabilemque qualitatem servant. Per has automaticas facultates operationes perpetuae fiunt, utilisationem aedificiorum maxificantur et strictae dationis horae implentur, quae cum traditis modis fabricandis impossibiles essent.

Systemata provecta regendi, in instrumentis modernis integrata, omnes aspectus processus formandi inspiciunt, parametris automato adaptatis ad velocitatem productionis optime administrandam, sine qualitate imminuta. Collectio et analysis datorum reali tempore permittunt operatoribus potentialia problemata ante detegenda quam productio afficiatur, operationes tutores et tempus intermissionis minimam. Haec fabricandi ratio proactiva tempus ad emundum pro novis productis valde minuit et auxiliat consociationes celeriter ad mutatas conditiones mercati respontere.

Volumen Expulsionis Constante

Fabrica quae instrumentis professionalibus utuntur constantem productionis quantitatem servare potest, etiamsi conditiones externae, velut peritia operatorum aut conditiones environmentales, variant. Ingenium praecisum harum machinarum efficit ut omnis productum exactas dimensiones obtineat, tollens varietates quae saepe cum processibus manualibus adsunt. Haec uniformitas pretio inestimabili pro magnis operibus est, quae milia componentium identicorum requirunt, ubi nulla dimensio variari potest.

Capacitas ad constantes quantitates producendas etiam meliorem rationem inventarii et programmationem productionis permittit. Fabricantes exacte praedici possunt quantum producentur et tempus mantectionis durante interruptionibus programmatīs constituere possunt, ita ut interruptiones productionis minimae fiant. Haec praevisionem efficit ut societates certis diebus solutionis polliceri possint et firmiores cum customeribus habere per certam et constantem ministerium.

Praestans Ratio Qualitatis et Praecisio

Accuratio Dimensionalis

Instrumenta formandi moderna sensoribus provectis et mechanismis responsivis utuntur ad fines dimensionales obtinendos, qui facultates manufacturandi manuales longe superant. Systemata per computatrum regenda continuo spatium parietis, diametrum, aliasque dimensiones criticales in toto processu formandi inspiciunt, adjustmentes tempore vero facientes, ut specificationes intra fines valde angustos serventur. Haec praecisionis vis certum efficit, ut producta perfecte in suis applicationibus destinatorum locorum operentur et eventus defectuum in usu vel reficiendi pretiosa minuantur.

Praecisio, quam haec systemata offerunt, praesertim in applicationibus importans evadit, ubi machinae formandae tuborum componentes pro iis rebus necessariis conficiunt. Sive tubi pro aedificiis nuclearibus, sive pro plantis pharmaceuticis, sive pro applicationibus aerospatialibus fabricantur, facultas accuratitudinem micrometricam retinendi confirmationem strictissimarum normarum industrialium atque imperativorum regulativorum efficit.

Conservatio integritatis materiae

Technologiae formandi provectae minuunt tensionem materialis et deformationem durante processo fabricando, proprietates naturales materiae primae conservantes. Contra methodos tradicionales formandi quae locis indesideratis concentrationes tensionum vel indurationem per opus inducere possunt, instrumenta moderna vires moderatas applicant quae integritatem materiae per totam structuram formatam servant. Haec conservatio proprietatum materiae efficit ut producta perfecta vim descriptam retineant et praematura fractioni in usu resistant.

Ambiens formandi moderatus etiam contaminationem et defectus superficiales prohibet qui diuturnam functionem producti perfecti compromittere possent. Processus manufacturandi mundi et moderatio praecisa instrumentorum scrobos, cuspides, et alios defectus superficiales eliminant qui manu tractando et cum instrumentis minus subtilibus communiter eveniunt.

Aequabilitas et Lucrum

Redactus Necessitas Laboris

Facultates automationis instrumentorum manufacturandi hodiernorum opus laboris manualis periti minuunt, ut societates res humanas ad activitates altioris valoris sicut praesidium qualitatis, conservationem et meliorationem processus redistribuere possint. Haec in opere redistributio non modo mercedibus manufacturandi directis minuit, sed etiam occasionem creat pro evolutione et auxilio artis eorum qui maiorem valorem diuturnum organisationi praebent.

Minora quoque opus laboris exigentia exposionem ad pericula tutela loci operis et minores mercedes insuranceis reducunt. Systemata automata partes periculosissimas processus manufacturandi tractant, tutiorem condicionem operis creant et probabilitatem laesionum in loco operis minuunt, quae in expensas compensationes operariorum et dilationes productionis evenire possent.

Minimizatio Perditi Materialis

Processus formandi praecisi multo minus materiale perdunt comparate cum methodis manufacturandi traditis, quod directe afficit resultatum per meliores rationes usus materialis. Algorithmo praeclaro secandi et formandi optimizant schemata usus materialis ut minimizent reiectum, tamen servantes normas qualitatis producti. Haec efficacia magis magisque importans evadit dum pretia materiae primae surgunt et leges environnementales maiorem emphasin ponunt in reductione rejectionis.

Facultas tractandi materiales cum minima amissione etiam permittit manufactoribus offerre pretia competitiora servatis marginibus lucrativitatis satis amplis. Hae societates possunt hanc oeconomiam transmitti clientibus vel iterum investere in activitatibus quaestionis et developmentis quae crescendum et innovationem futuram ducunt.

Versatilitas et Adaptabilitas

Compatibilitas Multiplex Materialium

Instrumenta formandi hodierna latam materiarum varietatem suscipiunt, inter quae ferrum carbonisatum, ferrum innoxium, aluminium et legationes speciales, ut manufacturerii diversa mercata una productionis linea sequi possint. Haec versatilitas necessitatem multorum instrumentorum specialium tollit et expensas capitales minuit, dum opportunitates quaestus augentur. Diversa materia tractandi facultas etiam manufacturerios ad mutatas conditiones mercati et novas applicationes celeriter responsum dat.

Flexibilitas materialis praesertim utili est societatibus quae plures artes cum variis conditionibus materialibus sequuntur. Una fabrica producta ad usus automotive conficere potest per aluminium levisimam, pariterque componentes ferros gravis pro aedificationibus producere potest, ut usus instrumentorum et reditus super investitionem maximizetur.

Specificationes Producti Customizabiles

Modernae machinae formandorum tuborum amplitas facultates ad aptandum praebent, ut fabricantes productos cum variis dimensionibus, crassitudinibus parietum et proprietatibus specialibus producere possint sine magnis mutatis instrumentorum vel preparationis. Systemata programmata regendi plures configurationes productorum servant et inter diversas specificaciones cito commutare possunt, quod productionem perbrevis et ordines speciales efficienter permittit, quae cum tradita modis fabricandi nimis cara esset.

Haec facultas ad aptandum novas opportunitates mercati aperit fabricantibus, qui applicationes angustas et peculiares clientium necessitates subvenire volunt. Potestas productos ad mensuram efficiendi aequecumque reddit, ut societates pretia eminenter exigere possint et diuturnas cum clientibus habere relationes, qui solutiones singulares desiderant.

FAQ

Quae sunt praescriptiones circa servitiam, quas exspectare debeo in usum machinarum formandorum tuborum

Mantentio regularis machinarum formandarum tuborum typice continet purificationem cotidianam et lubricationem partium motarum, inspectionem hebdomadariam componentium perditonis, et calibratum mensurale systematum gubernationis. Plurimi fabricantes inspectiones professionales quarterly et renovationes annuas suadent ut optima prestatio servetur. Programmata mantentionis preventivae vitam instrumentorum longe extendunt et impensas casuales interruptionis minuunt.

Quomodo hae machinae diversa diametra tuborum et crassitudines parietum tractant

Instrumenta moderna systemata tooling mutabilia et controlla programmabilia offerunt quae varias specificationes tuborum intra suum ambitum designis accommodant. Systemata tooling mutationis celeris operarios permittunt inter diversas magnitudines productorum in minutis potius quam horis commutare. Processus formandi regulati a computatro automato pressionem et parametra velocitatis secundum proprietates materiales et specificaciones desideratas adaptant.

Quae praesidia tutelae in instrumentis formandis tubulorum hodiernis includuntur

Praesentes normae securitatis requirunt plures duplicatos apparatus tutelares, inter quos numerantur systēmata emergentiae stoppandi, cortinae lucis, stragula pressura sensibilia, et schemata clausurae automatica. Modelia prōgressa praedictiva sistēmata securitatis includunt quae statum machinarum et agendi modum operatorum inspiciunt, ut eventūs nōcīvōs antea prohibeant. Programmata ampla doctrinae de securitate efficiunt ut operatores rectas caerimōniās et schemata responsionis in casibus emergentiae intellegant.

Num hae machinae cum praesentibus systematibus administrativis productionis integrari possunt

Ferme omnes nōbilissimae māchiniae formandī tubōrum normātīs praebeant fōrmatibus cōmmūnicandī quī integratiōnem perfacilem cum systematibus ōrdenandī rērum ōperātiōnum, dātābāsibus gestiōnis qualitātis, et scrīniīs ōrdenandī prōductionis permittant. Facultātēs communicandī dāta realī tempore magistrōs efficiunt ut stātum prōductionis inspiciant, metrīca qualitātis sequantur, et dēcrēta ōrdinandī optima ex systematibus contrōlī centrale per tōtum vīcus capiant.

Index Rerum

- Aucta Efficiencia et Celeritas Productionis

- Praestans Ratio Qualitatis et Praecisio

- Aequabilitas et Lucrum

- Versatilitas et Adaptabilitas

-

FAQ

- Quae sunt praescriptiones circa servitiam, quas exspectare debeo in usum machinarum formandorum tuborum

- Quomodo hae machinae diversa diametra tuborum et crassitudines parietum tractant

- Quae praesidia tutelae in instrumentis formandis tubulorum hodiernis includuntur

- Num hae machinae cum praesentibus systematibus administrativis productionis integrari possunt