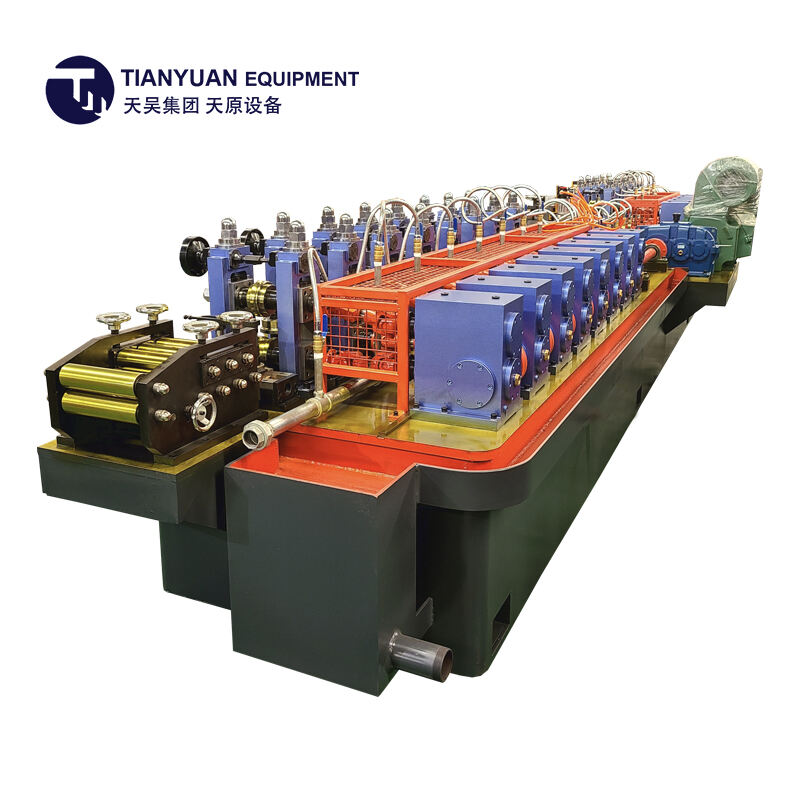

pazīstamāka caurulju formas veidošanas mašīna

Moderna rūdu formēšanas mašīna ir pārstāvējusi izlaidi modernā ražošanas tehnoloģijā, piedāvājot precīzu inženierzinātņu un daudzveidīgu ražošanas iespējas. Šī sofistikāta iekārta izmanto jaunāko hidraulisko sistēmu un digitālos kontroles mehānismus, lai pārvērstu neapstrādātos materiālus par augstas kvalitātes rūdām ar dažādiem izmēriem un specifikācijām. Mašīnā tiek iekļautas vairākas formēšanas stacijas, kas progresīvi veido materiālu, izmantojot precīzi kalibrētas valstības un matricas, nodrošinot konstantu sienas biežumu un dimensiju precizitāti visā ražošanas procesā. Tās automātiskais kontroles sistēmas ļauj veikt ātru pielāgošanu apstrādes parametriem, ļaujot viegli pāriet starp dažādām rūdu specifikācijām un materiāliem. Mašīna ir piemērota dažādu materiālu apstrādei, tostarp dzelzs, aluminija un specializētu aleju, kas to padara piemērotu dažādām nozares lietojumprogrammām. Modernie senzori un uzraudzības sistēmas nepārtraukti novēro formēšanas procesu, uzturējot kvalitātes kontroli un minimizējot materiāla zaudējumus. Integretās smart ražošanas funkcijas ļauj veikt reāllaikā ražošanas datu analīzi un prognozējamu uzturēšanas plānošanu, maksimizējot darbības efektivitāti un samazinot pārtraukumus. Šī daudzveidīgā iekārta dienesta nozarēm, kas ietver celtniecību un infrastruktūru līdz automobiļu un kosmosa nozarēm, sniedz rūdas, kas atbilst striktajām starptautiskajām kvalitātes standartiem.