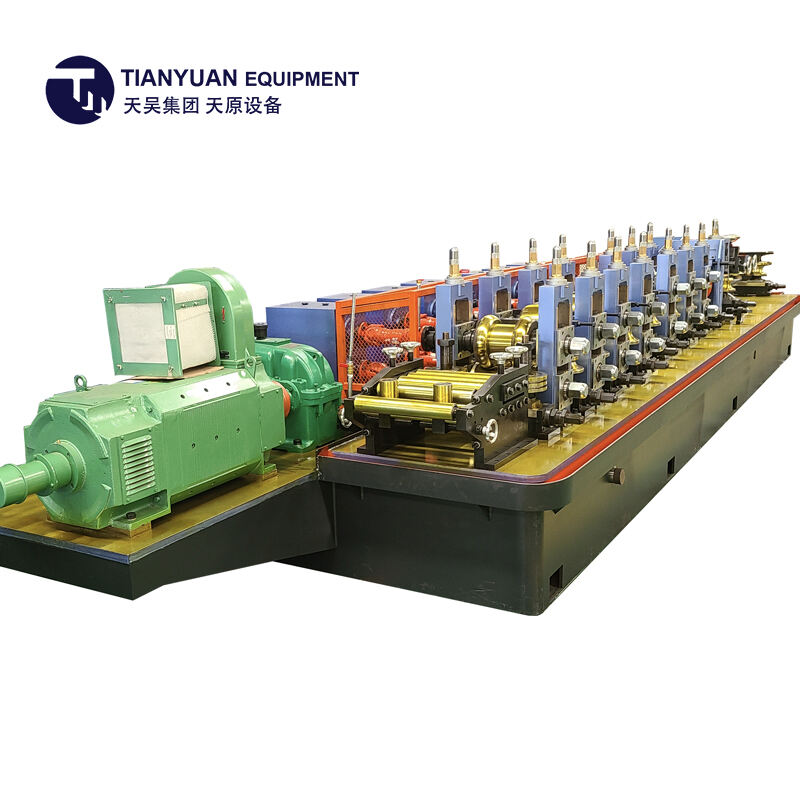

mesin membuat paip gi kualiti tinggi

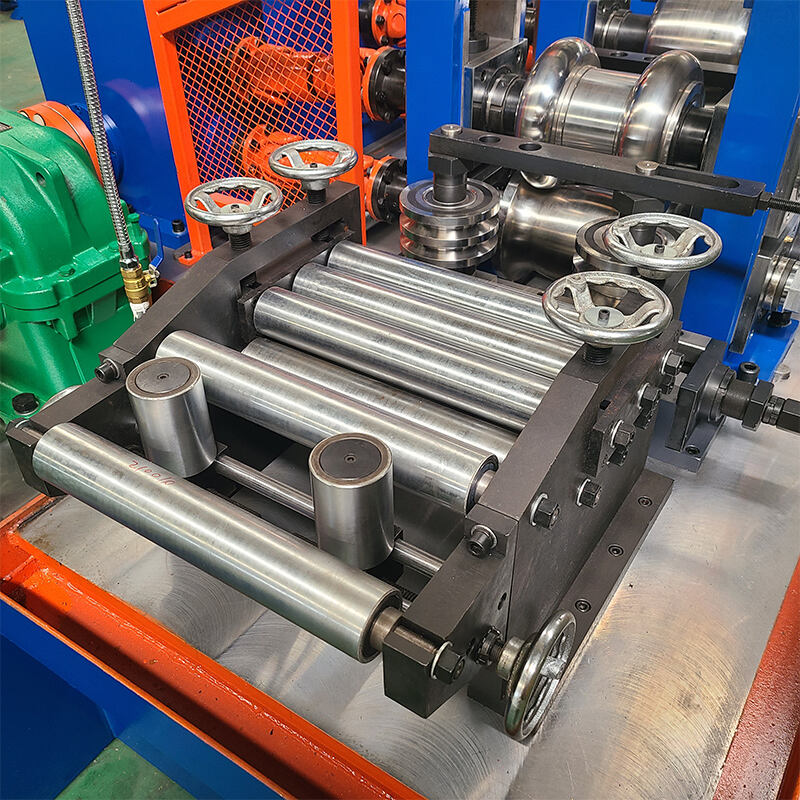

Mesin pembuatan paip GI berkualiti tinggi mewakili penyelesaian pengeluaran yang canggih direka untuk menghasilkan paip besi galvanised dengan ketepatan dan kecekapan luar biasa. Perlengkapan moden ini menggabungkan pelbagai peringkat pemprosesan, termasuk membuka gulungan, membentuk, menyambung, dan menggalvanis, semua dalam satu garis pengeluaran yang terpadu. Mesin ini menggunakan teknologi terkini untuk menukar jalur keluli mentah kepada paip silinder yang sempurna, sambil mengekalkan diameter dan ketebalan dinding yang konsisten sepanjang proses. Sistem kawalan automatiknya memastikan pemantauan tepat bagi parameter suhu, tekanan, dan kelajuan, menghasilkan paip yang mematuhi piawai kualiti antarabangsa. Mesin ini boleh menangani pelbagai spesifikasi paip, biasanya mengeluarkan diameter dari 15mm hingga 165mm, dengan ketebalan dinding dari 1.5mm hingga 6mm. Sistem penggalvanisan terpadu menerapkan lapisan zink yang seragam yang memberikan rintangan karat yang unggul, memanjangkan umur produk jadi. Ciri-ciri penting termasuk teknologi penyambungan frekuensi tinggi, kemampuan penyesuaian saiz automatik, dan mekanisme kawalan kualiti lanjutan yang mengesan dan menghalang kecacatan semasa pengeluaran. Mesin ini sangat dihargai dalam pembinaan, pembangunan infrastruktur, sistem bekalan air, dan aplikasi perindustrian di mana keupayaan dan kebolehpercayaan adalah utama.