အောင်မြင်သော လုပ်ဆောင်မှု hf ဆက်ထားသော ပိုင်းခြံတည်ဆောက်ရေး

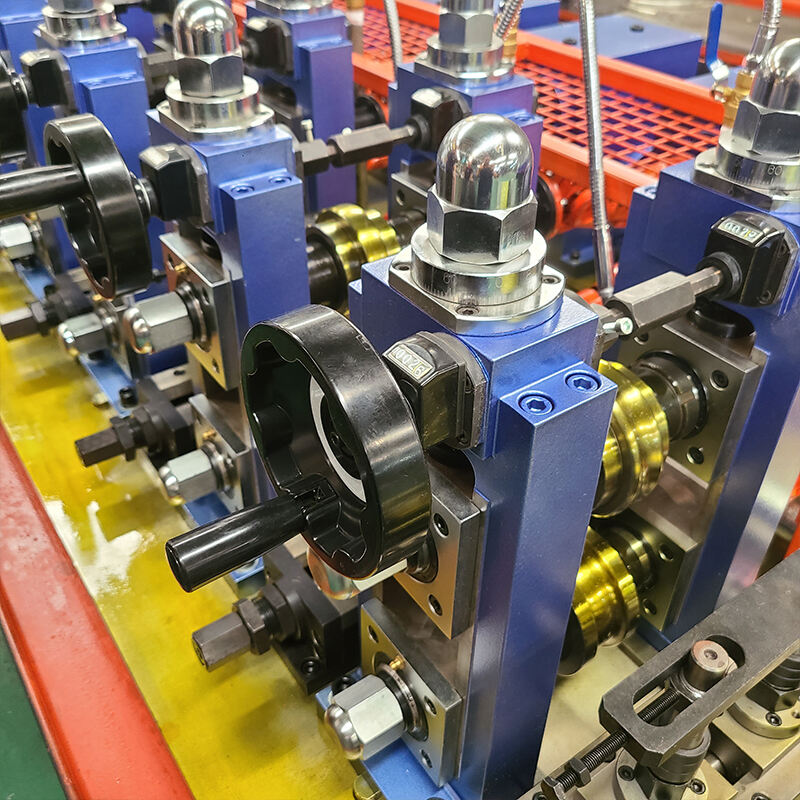

အောင်မြင်သော လုပ်ဆောင်မှု HF ဆက်စပ်ထုတ်ကုန်ရေးခန်းသည် စုံစမ်းသောဖြစ်စဉ်များကို ပြောင်းလဲသော ဖြစ်စဉ်တစ်ခုကို ကိုယ်စားပြုသည်။ ဒီအကောင့်မြင်သောစနစ်သည် မူလတွင် မြင့်မားသောလုပ်ဆောင်မှုကို ဖြစ်စေရန် အမြင်ကိုင်းလုပ်ငန်းနှင့် ကြိုတင်သော ထိန်ချခြင်းကို ပေါင်းစပ်ထားသည်။ ထုတ်ကုန်ရေးခန်းသည် ကျောက်ပြားကို အလုပ်သမားများအား ပေးဆောင်ခြင်း၊ ပိုင်းခြားသော ပြောင်းလဲမှု၊ ဆက်စပ်မှုနှင့် အရွယ်အစားတို့ကို လုပ်ဆောင်သည့် ရှုပ်ထွေးသောလုပ်ဆောင်မှုဖြင့် လုပ်ဆောင်သည်။ စနစ်၏ အဓိကလုပ်ဆောင်မှုသည် မြင့်မားသောလုပ်ဆောင်မှုကို ထိန်ချခြင်းနှင့် အပူချိန်ကို ကြိုတင်သော ထိန်ချခြင်းဖြင့် ထိန်ချခြင်းဖြင့် ထိန်ချသည်။ ထုတ်ကုန်ရေးခန်းသည် အချိန်တွင် မှန်ကန်သော လုပ်ဆောင်မှုများနှင့် ကိုယ်စားပြုလုပ်ဆောင်မှုများကို ပါဝင်သော အကောင်းဆုံးလုပ်ဆောင်မှုအချက်များကို စျေးနှုန်းပေးသည်။ အဲဒီထုတ်ကုန်ရေးခန်း၏ အထင်ရှားဆုံးအချက်တစ်ခုသည် အကောင်းဆုံးအရောင်းအရာရှိမှုစနစ်ဖြစ်ပြီး ပိုင်းခြားသော ဆက်စပ်မှုအရောင်းအရာရှိမှုကို အတူတူပေးသည်။ ထုတ်ကုန်ရေးခန်းသည် အလုံလုံပြည့်ပြည့်သော အရွယ်အစားများကို ထုတ်လုပ်နိုင်ပြီး မီးကိုင်း၊ ဆောက်လုပ်မှု၊ အခြားအခြား အခြေခံဖွံ့ဖြိုးမှု၊ ဆားနှင့်ဂိုးသားပို့ဆောင်မှုနှင့် အများသော အမျိုးအစားများတွင် အသုံးပြုနိုင်သည်။ စုံစမ်းသော အောက်ဆိုင်များနှင့် အရောင်းအရာရှိစနစ်များကို ပေါင်းစပ်ထားသည့်အပြင် ထုတ်လုပ်မှုကို မြင့်မားစွာ လုပ်ဆောင်နိုင်စေရန် ထုတ်ကုန်အရောင်းအရာရှိမှုကို ကိုက်ညီစေသည်။