The manufacturing industry continues to evolve with advanced machinery designed to enhance production efficiency and product quality. Among the most significant innovations in pipe manufacturing is the galvanized iron pipe making machine, which has revolutionized how businesses approach steel tube production. This sophisticated equipment offers manufacturers unprecedented control over the galvanization process while maintaining high-speed production capabilities. The integration of advanced technology in these machines has made it possible to produce consistent, high-quality galvanized pipes that meet stringent industry standards. Modern manufacturing facilities rely heavily on these specialized machines to maintain competitive advantage in the global marketplace.

Enhanced Production Efficiency and Speed

Automated Manufacturing Processes

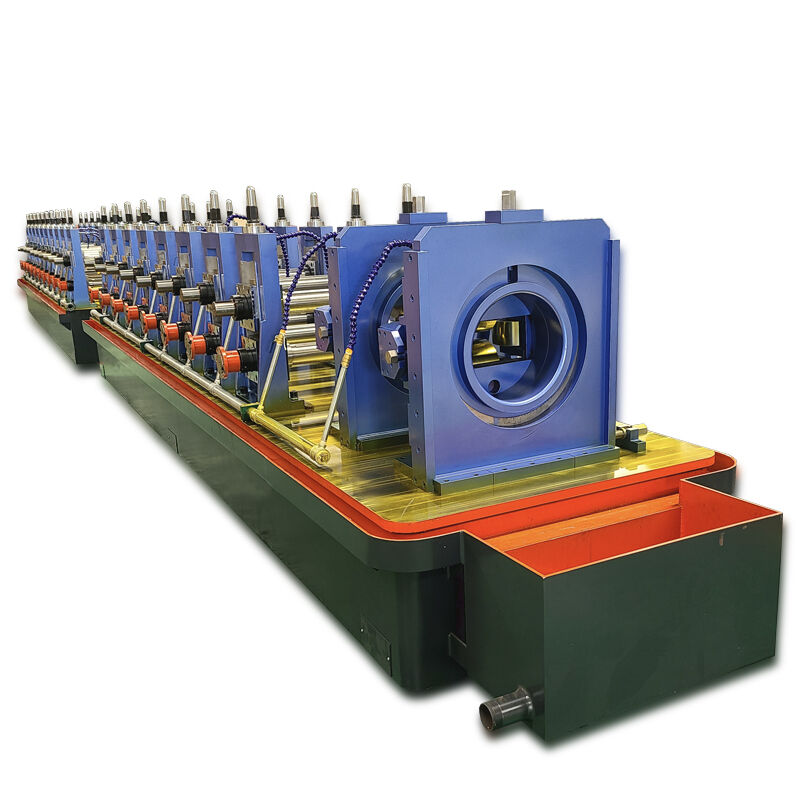

The galvanized iron pipe making machine incorporates advanced automation technology that significantly reduces manual labor requirements while increasing production throughput. These systems feature programmable logic controllers that manage every aspect of the manufacturing process, from material feeding to final product inspection. The automated nature of these machines ensures consistent production speeds that can reach impressive rates depending on pipe diameter and wall thickness specifications. Manufacturing facilities can achieve continuous operation cycles with minimal downtime, leading to substantial improvements in overall productivity metrics.

Advanced sensor technology integrated into modern galvanized iron pipe making machine systems provides real-time monitoring of production parameters. These sensors track critical variables such as forming speed, material thickness, and galvanization coating quality throughout the entire manufacturing process. The immediate feedback allows operators to make necessary adjustments quickly, preventing defective products from continuing through the production line. This proactive approach to quality control significantly reduces waste and maximizes the efficient use of raw materials.

Optimized Material Utilization

Precision engineering in galvanized iron pipe making machine design ensures optimal material utilization rates that minimize waste during production. The forming rollers and cutting mechanisms are calibrated to exact specifications, reducing material loss that typically occurs with less sophisticated manufacturing equipment. This efficiency translates directly into cost savings for manufacturers who process large volumes of steel coil material on a daily basis. The consistent material handling capabilities of these machines also reduce the likelihood of material damage during processing.

Modern galvanized iron pipe making machine systems feature advanced material tracking capabilities that monitor raw material consumption in real-time. This data enables production managers to optimize material ordering schedules and reduce inventory carrying costs. The precise material handling mechanisms also ensure that steel coils are utilized completely, with minimal end waste that would otherwise require recycling or disposal. These efficiency gains contribute significantly to the overall profitability of pipe manufacturing operations.

Superior Product Quality and Consistency

Precise Dimensional Control

The engineering precision built into each galvanized iron pipe making machine ensures that manufactured pipes meet exact dimensional specifications consistently. Advanced forming technology maintains tight tolerances on both internal and external pipe diameters, while sophisticated cutting systems provide clean, square cuts that eliminate the need for secondary finishing operations. This level of precision is crucial for applications where pipe connections must be leak-proof and structurally sound. The consistent dimensional accuracy also simplifies inventory management for distributors and end users.

Quality control systems integrated into modern galvanized iron pipe making machine operations include continuous measurement technologies that verify product dimensions throughout the manufacturing process. These systems can detect variations in wall thickness, diameter, or length that exceed specified tolerances and automatically adjust machine parameters to correct any deviations. The result is a consistently high-quality product that meets or exceeds industry standards for dimensional accuracy and structural integrity.

Uniform Galvanization Coverage

The galvanization process integrated into these specialized machines ensures uniform zinc coating application across the entire pipe surface. Advanced coating systems utilize precise chemical bath controls and temperature management to achieve consistent coating thickness that provides optimal corrosion resistance. The controlled environment within the Galvanized Iron Pipe Making Machine eliminates many variables that can affect coating quality in traditional galvanizing processes. This consistency is essential for pipes used in demanding applications where corrosion protection is critical.

Temperature control systems within galvanized iron pipe making machine operations maintain optimal conditions for zinc adherence and coating formation. These systems monitor and adjust galvanizing bath temperatures to ensure that the zinc coating bonds properly with the steel substrate, creating a durable protective layer. The controlled processing environment also eliminates contamination that can compromise coating quality, resulting in pipes with extended service life and reliable performance in corrosive environments.

Cost-Effective Manufacturing Solutions

Reduced Labor Requirements

Implementation of a galvanized iron pipe making machine significantly reduces the manual labor required for pipe production compared to traditional manufacturing methods. Automated feeding systems, forming processes, and cutting operations minimize the need for skilled operators while maintaining high production quality standards. This reduction in labor requirements translates into lower operational costs and improved profit margins for manufacturing facilities. The simplified operation also reduces the training time required for new operators and minimizes the risk of workplace injuries associated with manual material handling.

The streamlined operation of modern galvanized iron pipe making machine systems allows a single operator to oversee multiple production processes simultaneously. Advanced control interfaces provide clear visibility into all aspects of the manufacturing process, enabling efficient management of production schedules and quality parameters. This operational efficiency allows manufacturers to allocate human resources more effectively while maintaining consistent production output levels.

Energy Efficiency Optimization

Modern galvanized iron pipe making machine designs incorporate energy-efficient technologies that reduce power consumption while maintaining high production rates. Variable frequency drives control motor speeds based on actual production requirements, reducing energy waste during periods of lower demand. Heat recovery systems capture and reuse thermal energy from the galvanizing process, further reducing overall energy consumption. These efficiency improvements contribute significantly to reduced operating costs and improved environmental sustainability.

Advanced insulation and heat management systems in galvanized iron pipe making machine operations minimize energy loss during high-temperature processes. These systems maintain consistent operating temperatures with reduced energy input, while advanced control systems optimize heating cycles based on production schedules. The resulting energy savings can represent substantial cost reductions over the operating life of the equipment, improving the overall return on investment for manufacturing facilities.

Versatility and Customization Capabilities

Multiple Pipe Size Options

The adaptability of modern galvanized iron pipe making machine systems allows manufacturers to produce pipes in various sizes and specifications without requiring extensive equipment modifications. Quick-change tooling systems enable rapid transitions between different pipe diameters and wall thickness requirements, maximizing production flexibility. This versatility is particularly valuable for manufacturers serving diverse market segments with varying product specifications. The ability to switch between production runs efficiently reduces setup time and improves overall equipment utilization rates.

Advanced forming technology in galvanized iron pipe making machine designs accommodates a wide range of steel grades and material properties. This flexibility enables manufacturers to produce specialized pipes for specific applications while maintaining consistent quality standards. The robust construction of these machines ensures reliable performance across the full range of supported pipe sizes and specifications, providing manufacturers with confidence in their production capabilities.

Custom Configuration Options

Manufacturers can specify custom configurations for their galvanized iron pipe making machine to meet specific production requirements or facility constraints. Modular design approaches allow for the integration of additional processing stations, quality control systems, or material handling equipment based on individual needs. This customization capability ensures that each installation optimizes the available floor space while meeting specific production targets. The flexible design also accommodates future expansion requirements as production demands increase.

Integration capabilities built into galvanized iron pipe making machine systems allow seamless connection with existing factory automation systems and enterprise resource planning software. This connectivity enables real-time production monitoring, inventory management, and quality tracking that improves overall operational efficiency. The ability to integrate with existing systems reduces implementation costs and minimizes disruption to ongoing operations during equipment installation.

Advanced Technology Integration

Digital Control Systems

State-of-the-art digital control systems in modern galvanized iron pipe making machine operations provide precise control over every aspect of the manufacturing process. Touch-screen interfaces allow operators to monitor and adjust production parameters in real-time, while automated feedback systems maintain optimal operating conditions. These advanced controls enable consistent product quality while reducing the skill level required for effective machine operation. The digital systems also provide comprehensive data logging capabilities that support quality assurance and process improvement initiatives.

Predictive maintenance capabilities integrated into galvanized iron pipe making machine control systems monitor equipment performance and identify potential issues before they impact production. These systems track operating parameters, wear patterns, and performance trends to schedule maintenance activities during planned downtime. This proactive approach minimizes unexpected equipment failures and extends the operational life of critical machine components.

Quality Monitoring Systems

Integrated quality monitoring systems in galvanized iron pipe making machine installations provide continuous inspection of manufactured products throughout the production process. High-resolution cameras and laser measurement systems verify dimensional accuracy, surface quality, and coating uniformity on every pipe produced. This comprehensive quality control ensures that defective products are identified and removed before they reach customers. The automated inspection systems also generate detailed quality reports that support certification requirements and customer quality audits.

Advanced data analysis capabilities within galvanized iron pipe making machine quality systems identify trends and patterns that may indicate developing quality issues. This predictive quality management approach allows operators to make proactive adjustments to maintain consistent product quality. The comprehensive quality data also supports continuous improvement initiatives and helps manufacturers optimize their processes for better performance.

FAQ

What production capacity can be expected from a galvanized iron pipe making machine

Production capacity for a galvanized iron pipe making machine varies significantly based on pipe diameter, wall thickness, and specific machine configuration. Typical systems can produce between 50 to 200 meters per minute depending on these factors. Smaller diameter pipes generally achieve higher production speeds, while larger diameter or thicker-walled pipes require slower processing speeds to maintain quality standards. Modern high-efficiency machines often include multiple forming stations that can increase overall throughput while maintaining precise dimensional control.

How does the galvanization process integrate with pipe forming operations

The galvanization process in a galvanized iron pipe making machine typically occurs after the initial pipe forming and welding operations are completed. The formed pipe passes through a cleaning station to remove any surface contaminants, followed by flux application and controlled immersion in molten zinc baths. Temperature and immersion time are precisely controlled to ensure uniform coating thickness and proper zinc adherence. The integrated process ensures consistent coating quality while maintaining high production speeds throughout the manufacturing cycle.

What maintenance requirements are associated with these machines

Regular maintenance for a galvanized iron pipe making machine includes daily inspection of forming rollers, cutting mechanisms, and galvanizing bath chemistry. Weekly maintenance typically involves lubrication of moving components and calibration of measurement systems. Monthly maintenance includes more comprehensive inspection of wear components and replacement of consumable items such as cutting blades. The galvanizing bath requires periodic zinc replenishment and chemical balance adjustment to maintain optimal coating quality. Most modern systems include automated monitoring that alerts operators to maintenance requirements.

What safety considerations are important for galvanized pipe manufacturing

Safety considerations for galvanized iron pipe making machine operations include proper ventilation systems to manage fumes from the galvanizing process and appropriate personal protective equipment for operators. Emergency stop systems and safety interlocks prevent access to dangerous areas during operation. Regular training ensures operators understand proper procedures for handling molten zinc and managing chemical baths safely. Fire suppression systems and emergency response procedures are essential due to the high-temperature processes involved in galvanization. Proper material handling equipment reduces the risk of injury during coil loading and finished product removal operations.