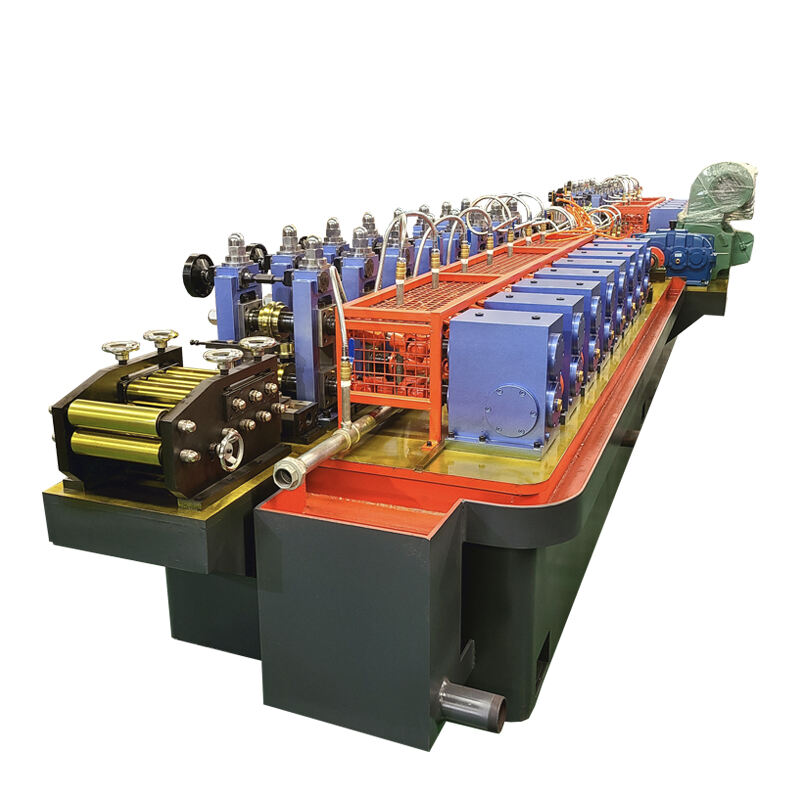

नविन डिझाइनको पाइप फॉर्मिंग मशीन

नवीनतम डिझाइन पाइप फॉर्मिंग मशीन औद्योगिक निर्माण प्रौद्योगिकीमा एक महत्वपूर्ण आगे बढ्दो को प्रतिनिधित्व गर्दछ, सटीक इंजिनियरिंगलाई स्वचालन दक्षतासँग मिश्रित गर्दछ। यस स्टेट-ऑफ-द-आर्ट सामानले एक सिस्टेमिक प्रक्रियाबाट सपाट धातु चापहरूलाई सटीक रूपमा फर्किएका पाइपमा परिवर्तन गर्दछ, जसमा रोलिङ्ग र वेल्डिङ्ग छ। मशीनमा एक अग्रणी नियन्त्रण प्रणाली छ, जसले निर्माणको प्रक्रियामा नियमित पाइप व्यास र दीवारको मोटाई ठेक्का राख्दछ। यसका मुख्य कार्यहरूमा स्वचालित सामग्री फीडिंग, बहुतिर रोलिङ्ग स्टेशनहरूद्वारा सटीक फार्मिंग, उच्च आवृत्ति वेल्डिङ्ग, र स्वचालित छेदन निर्दिष्ट लामिचाहिं छ। तकनीकी विशेषताहरूमा वास्तविक समयमा मॉनिटरिंग प्रणाली, डिजिटल कैलिब्रेशन क्षमता, र स्मार्ट समायोजन मेकनिज्म छन्, जसले सामग्री अपशिष्ट घटाउँदछ र निर्माण गति अधिकतम बनाउँदछ। यो मशीन कार्बन स्टील, स्टेनलेस स्टील, र एल्युमिनियम जस्ता विभिन्न सामग्रीहरूलाई प्रसेस गर्न सक्छ, जसको व्यास २०मिमी से २१९मिमीको रेंजमा हुन्छ। प्रणालीको विविधताले विभिन्न पाइप विनिर्देशहरूबीच त्वरित परिवर्तन गर्न सक्छ, जसले यसलाई बड़ी संख्यामा निर्माण र स्वयंसेवी निर्माण आवश्यकताहरूको लागि आदर्श बनाउँछ। अनुप्रयोगहरू निर्माण, ऑटोमोबाइल, फर्निचर निर्माण, र बुनियादी सुविधा विकास जस्ता बहुतै क्षेत्रहरूमा फैलेका छन्। मशीनको अग्रणी स्कार्फिङ्ग तकनीकले सफाई वेल्डिङ्ग बिडहरू विश्वसनीय बनाउँछ, जबकि एकीकृत ठांडो प्रणाली निरंतर निर्माणको लागि आदर्श संचालन तापमान बनाएराख्छ।