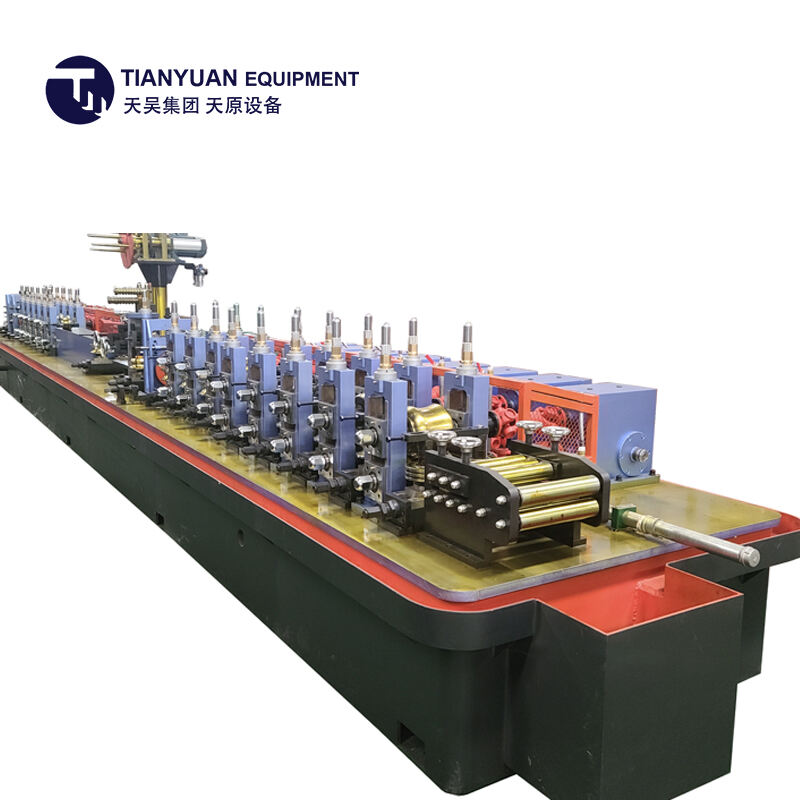

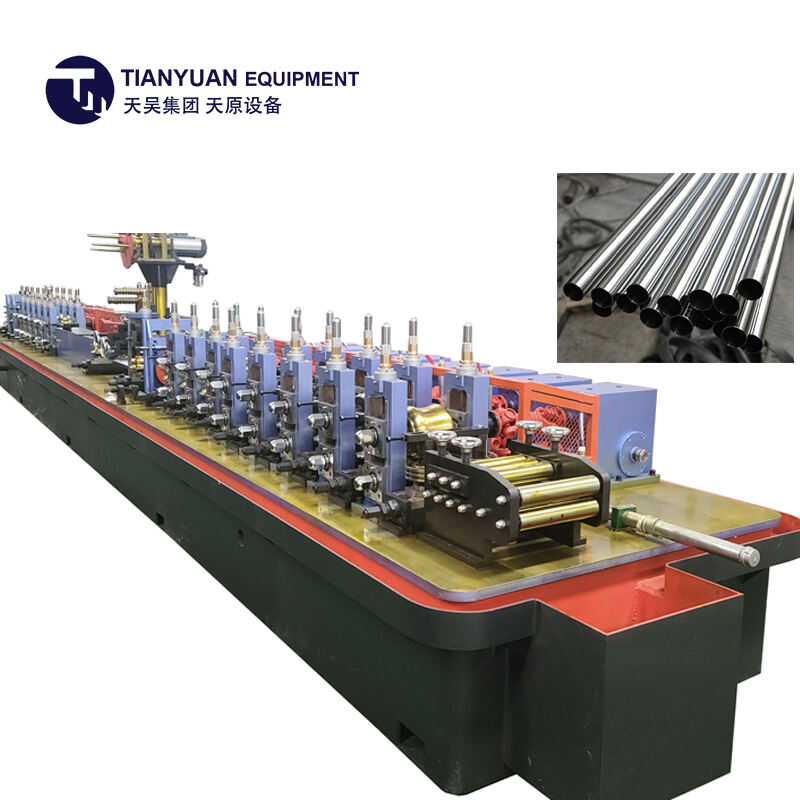

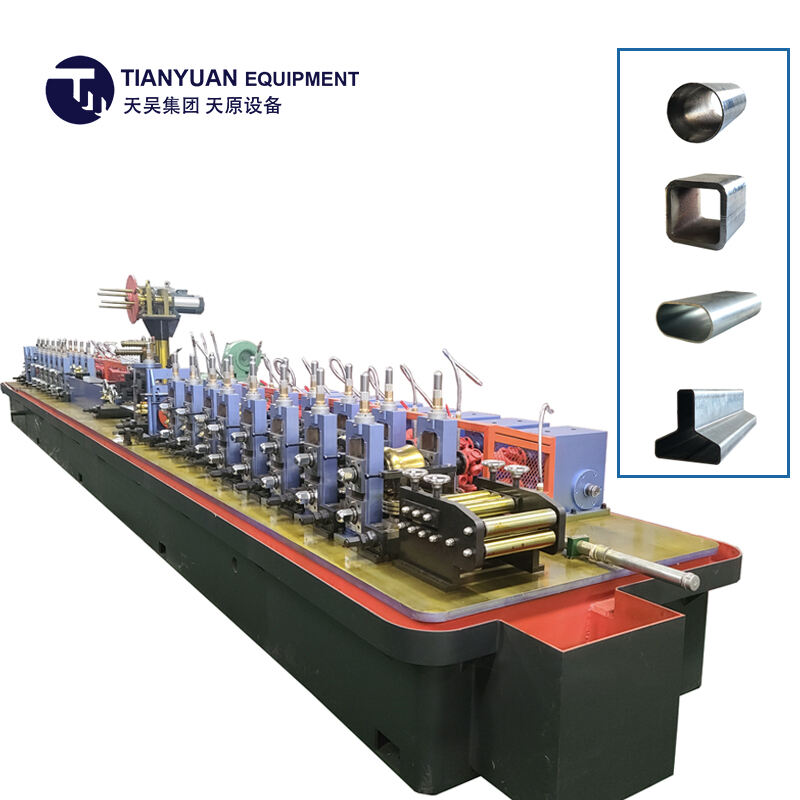

máquina personalizada de fabricação de tubos de aço carbono

A máquina personalizada para fabricação de tubos de aço carbono representa uma conquista na tecnologia moderna de manufatura, projetada para fornecer tubos com engenharia de precisão para várias aplicações industriais. Este equipamento avançado combina uma construção robusta com automação de ponta para produzir tubos de aço carbono de alta qualidade em várias dimensões e especificações. A máquina incorpora um sistema de controle sofisticado que monitora e ajusta parâmetros de produção em tempo real, garantindo qualidade consistente durante todo o processo de fabricação. Suas principais funções incluem alimentação de material, formação, soldagem, dimensionamento e corte, todos integrados em uma linha de produção contínua. A tecnologia apresenta capacidades avançadas de soldagem com sistemas de soldagem por indução de alta frequência, mecanismos de controle dimensional preciso e protocolos automatizados de inspeção de qualidade. A máquina pode lidar com diferentes tipos de aço e espessuras de parede, tornando-a versátil para diversas necessidades industriais. Com velocidades de produção de até 80 metros por minuto, ela aumenta significativamente a eficiência da manufatura enquanto mantém padrões rigorosos de qualidade. O design adaptável da máquina permite mudanças rápidas entre diferentes especificações de tubos, minimizando tempos de inatividade e maximizando a produtividade. Ela é particularmente adequada para produzir tubos utilizados na construção, transporte de petróleo e gás, sistemas de abastecimento de água e aplicações estruturais.