Современные производственные предприятия все чаще используют передовые технологии автоматизации для удовлетворения растущего спроса на высококачественные стальные трубы в строительной, нефтегазовой и инфраструктурной отраслях. Внедрение сложных технологий производства труб из углеродистой стали произвело революцию в производственных возможностях, позволив производителям достичь беспрецедентного уровня эффективности при сохранении строгих стандартов качества. Эти машины представляют собой значительный шаг вперед по сравнению с традиционными методами производства труб, сочетая в себе высокоточное проектирование и автоматизированное управление, что оптимизирует весь производственный процесс.

Интеграция передовых технологий в современное производство труб

Системы высокочастотной сварки

В основе любой эффективной машины для производства труб из углеродистой стали лежит технология сварки. Системы высокочастотной сварки стали отраслевым стандартом благодаря своей способности создавать бесшовные, равномерные сварные швы с невероятной скоростью. Эти системы работают за счет генерации электромагнитных полей, которые нагревают кромки стали до температуры сварки без внешнего пламени или присадочных материалов. Точность высокочастотной сварки обеспечивает равномерное распределение тепла по всей зоне сварки, что приводит к более прочным соединениям и уменьшению отходов материала.

Современные конструкции станков для производства труб из углеродистой стали включают в себя передовую технологию индукционного нагрева, которая позволяет точно контролировать температуру в процессе сварки. Это технологическое достижение значительно снижает энергопотребление, одновременно повышая стабильность качества сварных швов. Автоматизированный характер этих систем исключает влияние человеческого фактора, который традиционно влиял на целостность сварного шва, гарантируя, что каждая труба соответствует или превосходит отраслевые стандарты.

Системы компьютерного управления формированием

Современные технологии формовки труб в значительной степени основаны на системах компьютерного управления, которые контролируют и корректируют процесс формовки в режиме реального времени. Эти сложные системы управления используют множество датчиков для отслеживания толщины материала, температуры и давления формовки на протяжении всего производственного цикла. Интеграция программируемых логических контроллеров позволяет операторам быстро переключаться между различными характеристиками труб без длительных процедур настройки, что значительно повышает гибкость производства.

Точность, обеспечиваемая системами компьютерного управления в станках для изготовления труб из углеродистой стали, выходит за рамки базовых операций формовки. Эти системы могут компенсировать вариации материала, факторы окружающей среды и износ формовочных инструментов, поддерживая стабильную точность размеров на протяжении длительных производственных циклов. Такой уровень контроля напрямую приводит к снижению брака и повышению общей эффективности оборудования.

Оптимизация скорости производства и производительности

Возможности непрерывного производства

Переход от пакетной обработки к непрерывному производству представляет собой одно из наиболее значительных улучшений эффективности в производстве труб из углеродистой стали. Современные станки могут работать непрерывно в течение длительных периодов времени, перерабатывая сырье в готовые трубы без перерывов. Непрерывная работа исключает простои, связанные с переналадкой оборудования для пакетной обработки, и позволяет производителям поддерживать стабильные производственные графики, соответствующие требованиям заказчиков по срокам поставки.

Непрерывное производство на станке для изготовления труб из углеродистой стали обеспечивается автоматизированными системами подачи материала, гарантирующими стабильную скорость подачи и неизменно высокое качество материала. Эти системы могут работать с различными марками и толщинами стали, поддерживая при этом оптимальную скорость производства. Возможность обработки различных материалов без существенных корректировок дополнительно повышает эффективность работы и сокращает сроки выполнения производственных заказов.

Эффективность многостанционной обработки

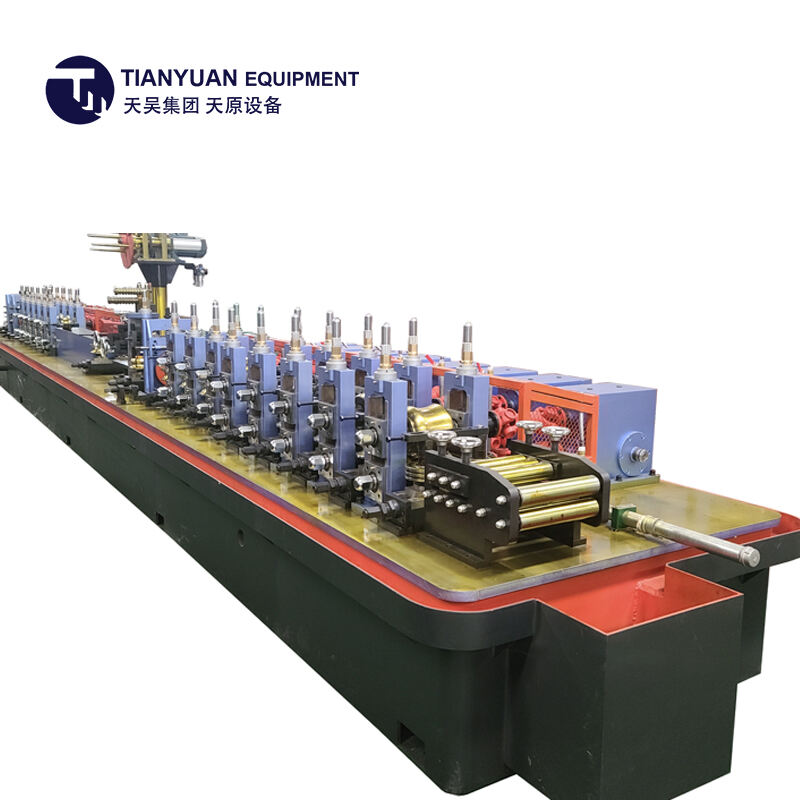

Современное оборудование для производства труб включает в себя несколько обрабатывающих станций, работающих параллельно для максимальной производительности. Каждая станция выполняет определенные операции, такие как размотка, формовка, сварка и калибровка, что позволяет обрабатывать несколько труб одновременно на разных этапах производства. Такой подход к параллельной обработке значительно увеличивает производительность в час по сравнению с методами последовательной обработки.

Для координации работы нескольких технологических станций требуются сложные системы управления, синхронизирующие операции по всей производственной линии. Хорошо спроектированная система машина для производства стальных труб из углеродистой стали Обеспечивает бесперебойный поток материалов между станциями, сохраняя при этом контроль качества на каждом этапе обработки. Такой уровень интеграции устраняет узкие места, которые традиционно ограничивали производственные мощности, и позволяет производителям удовлетворять растущий спрос рынка.

Контроль качества и улучшение стабильности

Системы мониторинга в реальном времени

Современные установки для производства труб из углеродистой стали оснащены комплексными системами мониторинга, отслеживающими критически важные параметры качества на протяжении всего производственного процесса. Эти системы непрерывно измеряют точность размеров, равномерность толщины стенки и целостность сварных швов с помощью неразрушающих методов контроля. Сбор данных в режиме реального времени позволяет операторам выявлять и устранять потенциальные проблемы качества до того, как они приведут к появлению дефектной продукции.

Внедрение мониторинга в режиме реального времени значительно сократило задержки производства, связанные с качеством, и количество жалоб клиентов. Современные системы могут автоматически корректировать параметры обработки на основе поступающих данных о качестве, обеспечивая стабильное качество продукции независимо от изменений материалов или условий окружающей среды. Такой проактивный подход к контролю качества значительно повышает процент выхода годной продукции с первого раза и снижает необходимость в дорогостоящих операциях по доработке.

Автоматизированная проверка и тестирование

Автоматизированные системы контроля качества, интегрированные в конструкции станков для производства труб из углеродистой стали, проводят всестороннюю оценку качества без замедления темпов производства. Эти системы используют передовые технологии визуализации, ультразвуковой контроль и инструменты для измерения размеров, чтобы оценить каждую произведенную трубу. Автоматизированный контроль устраняет субъективность и непоследовательность, связанные с ручными методами проверки, и обеспечивает подробную документацию для целей обеспечения качества.

Данные, полученные с помощью автоматизированных систем контроля, предоставляют ценную информацию о производительности процесса и состоянии оборудования. Производители могут анализировать тенденции качества для оптимизации параметров обработки и прогнозирования потребностей в техническом обслуживании. Такой подход к управлению качеством, основанный на данных, поддерживает инициативы по непрерывному совершенствованию и помогает сохранять конкурентные преимущества в сложных рыночных условиях.

Энергоэффективность и экологические преимущества

Оптимизированное энергопотребление

В современных конструкциях станков для производства труб из углеродистой стали приоритет отдается энергоэффективности за счет оптимизированных систем управления питанием и эффективных приводных технологий. Частотно-регулируемые приводы регулируют скорость вращения двигателя в соответствии с производственными требованиями, снижая энергопотребление в периоды снижения спроса. Усовершенствованные системы коррекции коэффициента мощности минимизируют потребление реактивной мощности, что приводит к снижению затрат на электроэнергию и уменьшению воздействия на окружающую среду.

Интеграция систем рекуперации энергии в современное оборудование для производства труб позволяет улавливать и повторно использовать отработанное тепло, выделяющееся в процессе сварки. Эта рекуперированная энергия может быть использована для предварительного нагрева поступающих материалов или для обеспечения потребностей предприятия в отоплении. Такие повышения эффективности не только снижают эксплуатационные расходы, но и способствуют реализации корпоративных инициатив в области устойчивого развития и соблюдению экологических норм.

Сокращение отходов и оптимизация материалов

Современные станки для производства труб из углеродистой стали с высокоточным управлением значительно сокращают потери материала за счет оптимизации схем резки и минимизации требований к обрезке. Усовершенствованные алгоритмы раскроя максимизируют использование материала из поступающих стальных рулонов, а автоматизированные системы резки обеспечивают точный контроль длины. Эти улучшения напрямую влияют на стоимость сырья и снижают экологическую нагрузку, связанную с утилизацией отходов.

Возможность обработки стали различных марок и толщин на одном и том же оборудовании снижает потребность в складских запасах и позволяет производителям быстро реагировать на меняющиеся требования заказчиков. Такая гибкость минимизирует риски, связанные с устаревшими запасами, и поддерживает стратегии производства «точно в срок», что дополнительно повышает эффективность работы.

Снижение затрат и возврат инвестиций

Повышение эффективности труда

Современные системы автоматизации в станках для производства труб из углеродистой стали значительно сокращают трудозатраты, повышая при этом безопасность и производительность труда. Автоматизированная обработка материалов исключает ручные операции по подъему и перемещению, которые традиционно требовали участия нескольких операторов. Системы с компьютерным управлением снижают уровень квалификации, необходимый для выполнения рутинных операций, упрощая обучение новых операторов и поддерживая стабильные производственные мощности.

Сокращение прямых затрат на рабочую силу выходит за рамки простого сокращения численности персонала и включает в себя повышение эффективности труда и снижение потребности в сверхурочных работах. Автоматизированные системы могут работать в нерабочее время с минимальным контролем, что позволяет производителям максимально эффективно использовать оборудование без пропорционального увеличения затрат на рабочую силу. Эти повышения эффективности вносят существенный вклад в улучшение рентабельности и конкурентоспособности.

Оптимизация затрат на обслуживание

Встроенные в современные станки для производства труб из углеродистой стали возможности прогнозирующего технического обслуживания помогают минимизировать непредвиденные простои и продлить срок службы оборудования. Системы мониторинга состояния отслеживают вибрацию, температуру и другие ключевые параметры, чтобы выявлять потенциальные проблемы до того, как они приведут к поломкам оборудования. Такой проактивный подход к техническому обслуживанию значительно снижает затраты на ремонт и перебои в производстве.

Модульная конструкция современного трубопрокатного оборудования ускоряет процедуры технического обслуживания и сокращает запасы необходимых запасных частей. Стандартизированные компоненты и улучшенная доступность позволяют ремонтным бригадам более эффективно выполнять рутинные работы. Эти конструктивные усовершенствования способствуют снижению общей стоимости владения и повышению рентабельности инвестиций в оборудование.

Часто задаваемые вопросы

Какие факторы определяют эффективность станка для производства труб из углеродистой стали?

Эффективность станка для производства труб из углеродистой стали зависит от нескольких ключевых факторов, включая технологию сварки, уровень автоматизации, скорость производства и системы контроля качества. Системы высокочастотной сварки обеспечивают более быстрые и стабильные результаты по сравнению с традиционными методами. Передовая автоматизация снижает необходимость ручного вмешательства, сохраняя при этом точный контроль над критически важными параметрами. Интеграция систем мониторинга в реальном времени и автоматизированного контроля гарантирует стабильное качество продукции при оптимальной скорости производства.

Чем современные станки отличаются от традиционных методов производства труб?

Современные технологии производства труб из углеродистой стали предлагают существенные преимущества по сравнению с традиционными методами изготовления с точки зрения скорости, стабильности и экономической эффективности. Современные станки позволяют производить трубы со значительно большей скоростью, сохраняя при этом превосходную точность размеров и качество сварных швов. Автоматизированные системы исключают многие факторы, связанные с человеческим фактором, которые влияли на традиционные процессы, что приводит к более предсказуемым результатам и сокращению отходов. Возможности непрерывного производства современного оборудования также обеспечивают более эффективное использование производственных мощностей по сравнению с методами пакетной обработки.

Какие требования к техническому обслуживанию следует ожидать от современного оборудования для производства труб?

Современные установки для производства труб из углеродистой стали требуют регулярного профилактического обслуживания для поддержания оптимальной производительности и продления срока службы оборудования. Плановые работы по техническому обслуживанию включают проверку системы смазки, замену сварочных электродов и калибровку измерительных систем. Современные системы мониторинга обеспечивают раннее предупреждение о потенциальных проблемах, позволяя ремонтным бригадам планировать ремонт во время плановых простоев. Большинство производителей рекомендуют создавать комплексные программы технического обслуживания, включающие как плановое обслуживание, так и обслуживание по состоянию оборудования.

Насколько быстро можно изменять производственные параметры для труб различной спецификации?

Современные системы для производства труб из углеродистой стали разработаны для быстрой переналадки между различными спецификациями труб с минимальными перебоями в производстве. Системы с компьютерным управлением могут хранить множество рецептур продукции, которые автоматически регулируют параметры формовки, настройки сварки и длину резки. Типичное время переналадки для регулировки размеров составляет от 15 до 30 минут в зависимости от сложности изменений спецификации. Такая гибкость позволяет производителям быстро реагировать на требования заказчиков и поддерживать эффективные производственные графики для различных ассортиментов продукции.

Содержание

- Интеграция передовых технологий в современное производство труб

- Оптимизация скорости производства и производительности

- Контроль качества и улучшение стабильности

- Энергоэффективность и экологические преимущества

- Снижение затрат и возврат инвестиций

-

Часто задаваемые вопросы

- Какие факторы определяют эффективность станка для производства труб из углеродистой стали?

- Чем современные станки отличаются от традиционных методов производства труб?

- Какие требования к техническому обслуживанию следует ожидать от современного оборудования для производства труб?

- Насколько быстро можно изменять производственные параметры для труб различной спецификации?