Savremena proizvodnja zahteva izuzetnu preciznost, a mašine za proizvodnju čeličnih cevi su se razvile da bi ispunile ove stroge zahteve kroz napredno inženjerstvo i sofisticirane kontrolne sisteme. Ovi industrijski pogoni kombinuju mehanički sjaj sa najnovijom tehnologijom kako bi proizvodili cevi koje zadovoljavaju tačne specifikacije u različitim primenama. Preciznost koju postižu savremene mašine za proizvodnju čeličnih cevi transformisala je industrije od građevinarstva do proizvodnje automobila, gde dimenziona tačnost može značiti razliku između uspeha i neuspeha u kritičnim primenama.

Napredni kontrolni sistemi u savremenoj proizvodnji cevi

Integracija računarski numeričkog upravljanja

Temelj preciznosti u modernim mašinama za proizvodnju čeličnih cevi leži u sofisticiranim računarskim sistemima numeričkog upravljanja koji nadgledaju i podešavaju svaki aspekt procesa proizvodnje. Ovi sistemi kontinuirano prate parametre poput brzina dovođenja materijala, pritisaka pri oblikovanju i dimenzionih mera u realnom vremenu. Napredni senzori postavljeni na raznim delovima mašine omogućavaju trenutnu povratnu spregu, što dopušta odmah ispravke kojima se održavaju tolerancije unutar delova milimetra. Integracija algoritama veštačke inteligencije omogućava ovim sistemima da predvide moguća odstupanja pre nego što se dogode, osiguravajući konzistentan kvalitet tokom celokupne serije proizvodnje.

Вишеосни серво мотори раде у савршеној синхронизацији како би контролисали кретање ваљака за обликовање, сечених механизама и система за руковање материјалом. Ова прецизна координација елиминише механичко лупање и поновне удара који могу унети варијације у традиционалној производној опреми. Резултат је ниво понављања који омогућава произвођачима да производе хиљаде идентичних цеви са минималним одступањима, испуњавајући строге стандарде потребне у индустријама као што су аеропростор и прецизно инжењерство.

Sistemi za stvarno-vremenski nadzor kvaliteta

Savremene proizvodne instalacije koriste sofisticirane sisteme za nadzor kvaliteta koji procenjuju svaku proizvedenu cev bez usporavanja linije za proizvodnju. Sistemi laserskog merenja skeniraju spoljašnje dimenzije cevi dok se one kreću kroz proces proizvodnje, otkrivajući varijacije male čak i do 0,01 milimetar. Ovi sistemi mogu da identifikuju probleme kao što su ovalnost, varijacije u debljini zida i površinske nepravilnosti koje bi mogle da ugroze rad finalnog proizvoda.

Digitalna tehnologija snimanja u kombinaciji sa algoritmima mašinskog učenja analizira kvalitet površine i otkriva mikroskopske nedostatke koje ljudski inspektori mogu propustiti. Kada se otklone odstupanja od specifikacija, sistem automatski prilagođava parametre procesa ili označava proizvode za ručnu kontrolu. Ovaj pristup kontinuiranog nadzora osigurava da se problemi sa kvalitetom reše odmah, a ne da se otkriju kasnije, čime se smanjuje otpad i održava konzistentan kvalitet izlaza.

Прецизно инжењерство у пројектовању машина

Компоненте за производњу са високим степеном тачности

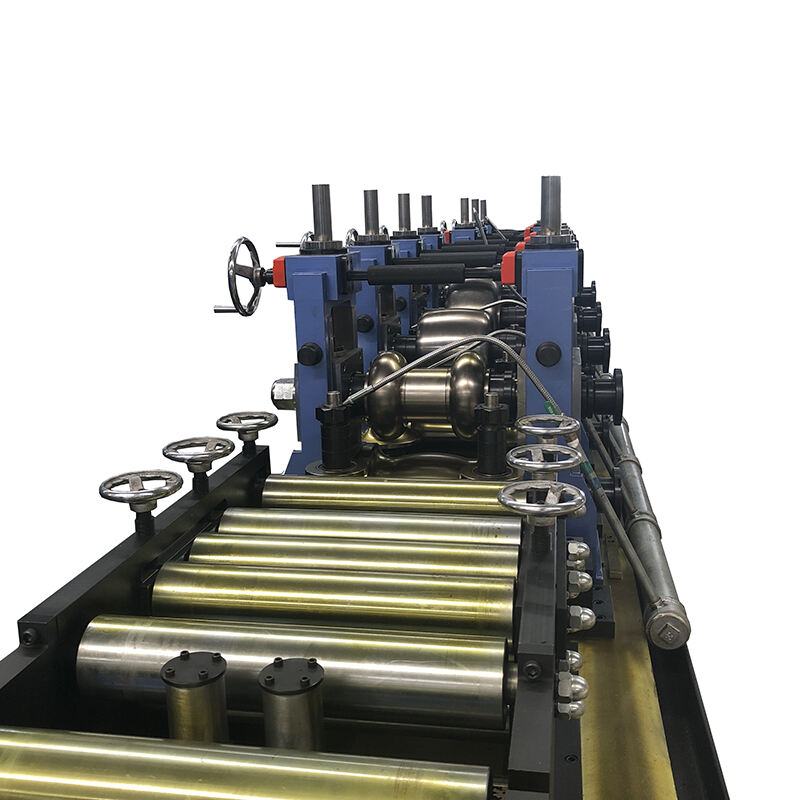

Механички компоненти унутар mašine za proizvodnju čelikovih cevi се израђују са веома малим толеранцијама како би се осигурала стална перформанса током дужег временског периода. Валјци за обликовање су прецизно брушени да би се одржала површинска испољавања мерена у микринчима, док су склопови лежајева одабрани и позиционирани са зазорима мереним у хиљадитим деловима инча. Ова пажња према механичкој прецизности директно се преводи у димензионалну тачност готових цеви.

Напредна металургија у производњи компоненти осигурава да критични делови задрже димензионалну стабилност под екстремним силама и температурама које настају током процеса формирања цеви. Алатни челици и специјализирани легури отпорни су на хабање и деформације, одржавајући свој прецизан геометријски облик кроз милионе радних циклуса. Редовни поступци калибрације и одржавања обезбеђују да ови делови наставе да раде у оквиру задатих спецификација, очувајући способност машине да производи прецизне производе.

Контрола температуре и термална стабилност

Varijacije temperature mogu značajno uticati na dimenzionu tačnost proizvodnje čeličnih cevi, zbog čega je termičko upravljanje ključan aspekt precizne proizvodnje. Savremene mašine uključuju sofisticirane sisteme hlađenja i grejanja koji održavaju stabilne temperature tokom celokupnog procesa oblikovanja. Kola hlađenja sa precizno kontrolisanim protokom tečnosti odvode višak toplote iz kritičnih komponenti, dok zagrevani delovi osiguravaju optimalnu obradivost materijala.

Sistemi kompenzacije termičkog širenja automatski podešavaju geometriju mašine kako bi nadoknadili dimenzione promene izazvane temperaturom u samoj opremi. Ovi sistemi koriste precizne senzore pomeraja i automatizovane mehanizme za podešavanje kako bi održali kritična rastojanja i poravnanja tokom promena radnih temperatura. Rezultat su konzistentne dimenzije cevi bez obzira na spoljašnje uslove ili varijacije u ciklusima proizvodnje.

Rukovanje materijalom i preciznost dovođenja

Priprema i poravnanje ivica trake

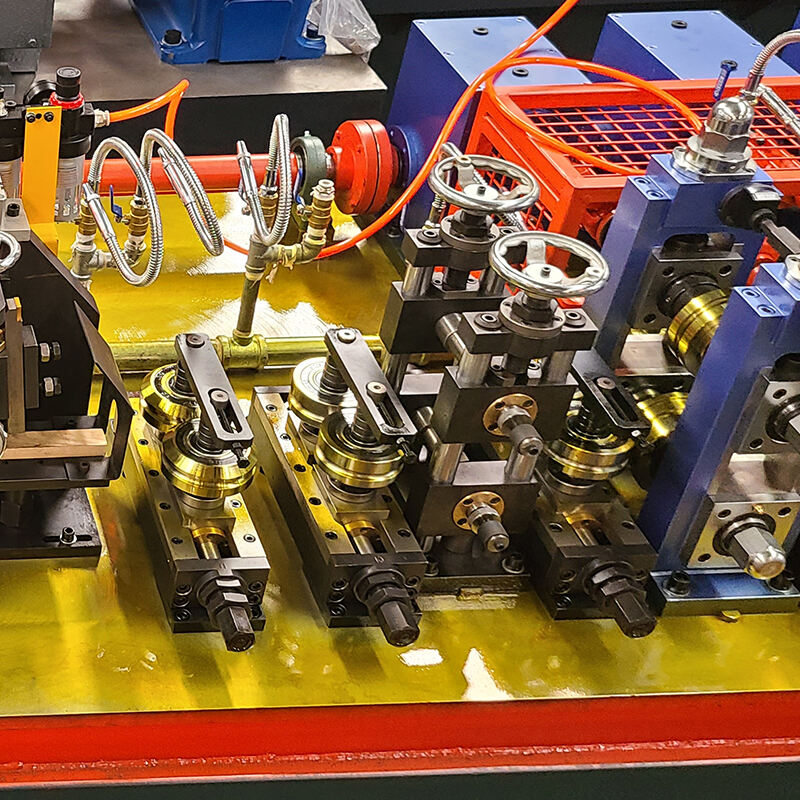

Прецизност коначног производа цеви започиње детаљном припремом и руковањем траком сировог материјала. Напредни системи за обрезивање ивица осигуравају да су ивице челичне траке савршено равне и слободне од оштрица или неправилности које би могле утицати на процес заваривања. Валјци за прецизно исправљање уклањају све остатне напоне или закривљеност из долазног материјала, стварајући идеалну основу за конзистентно формирање цеви.

Оптички системи поравнања континуирано прате положај траке и аутоматски подешавају механизме вођења како би одржали савршено централно праћење током целокупног процеса формирања. Ови системи могу открити бочни помак мерен у деловима милиметра и тренутно извршити корекције како би спречили варијације димензија код готове цеви. Елиминисање блуждања траке осигурава да дебљина зида остане једнолика по целој обиму цеви.

Контрола напона и управљање током материјала

Održavanje konstantnog napona u traci od čelika dok prolazi kroz proces oblikovanja od suštinskog je značaja za proizvodnju cevi sa uniformnim dimenzijama i mehaničkim osobinama. Napredni sistemi za kontrolu napona koriste senzore opterećenja i servo-kontrolisane kočne mehanizme kako bi održali optimalni napon trake tokom čitave proizvodne linije. Ovi sistemi automatski kompenzuju varijacije u svojstvima materijala, debljini trake i brzinama oblikovanja.

Pogoni sa promenljivom frekvencijom i precizna kontrola brzine osiguravaju da stopa protoka materijala ostane konstantna, bez obzira na promene u zahtevima nizvodnih procesa. Sistemi za privremeno skladištenje prilaze sitnim razlikama u brzinama obrade između različitih stanica, istovremeno održavajući kontinuiran protok materijala. Pažljivo upravljanje kretanjem materijala sprečava istezanje, sabijanje ili deformaciju koje bi mogli narušiti dimenzionu tačnost.

Preciznost zavarivanja i kvalitet šava

Tehnologija visokofrekvencijske svarenja

Креирање савршеног уздужног шава захтева изузетну прецизност како у позиционирању, тако и у примени енергије. Системи високе фреквенције у модерним машинама за производњу челичних цеви обезбеђују прецизно контролисану енергију ради стварања зона спајања са константном ширином и продираним дубинама. Ови системи прате параметре заваривања хиљаду пута у секунди, правећи микроподешавања како би одржали оптималне услове заваривања.

Мреже за усклађивање импедансе осигуравају да се енергија за заваривање доставља са максималном ефикасношћу и минималним варијацијама, стварајући шавове са једноликим механичким карактеристикама на целој њиховој дужини. Напредни дизајни електрода и системи за позиционирање одржавају сталан контакт са ивицама траке од челика, елиминишући варијације које би могле створити слабе тачке или димензионалне неправилности у готовом шаву.

Инспекција шава и осигурање квалитета

Системи за непосредну контролу након заваривања процењују квалитет шава коришћењем више метода детекције, укључујући ултразвучно тестирање, испитивање вртлог струјама и визуелну анализу. Ови системи могу открити непотпуну фузију, укључења или друге дефекте заваривања који би могли да угрозе интегритет цеви. Аутоматизовани системи одбацивања уклањају дефектне делове из производног тока без човечке интервенције.

Системи за континуирано праћење шава прате позицију и квалитет завареног шава током целокупног производног процеса, омогућавајући повратне информације за оптимизацију процеса у реалном времену. Алгоритми статистичке контроле процеса анализирају податке о квалитету шава како би идентификовали трендове и предвидели могуће проблеме пре него што дође до производње неисправних производа. Овакав проактивни приступ управљању квалитетом одржава конзистентне стандарде производње и минимизира отпад.

Контрола димензија током целокупне производне линије

Прогресивне фазе формирања

Трансформација равне челичне траке у прецизне кружне или квадратне профиле цеви одвија се кроз пажљиво контролисане прогресивне фазе обликовања. Свака појединачна фаза доприноси одређеном степену закривљености, при чему заједнички ефекат ствара коначну геометрију цеви. Валјци за прецизно обликовање постављени су са микрометарском тачношћу како би се осигурало да свака фаза допринесе тачно потребној количини деформације.

Механизми подешавања под контролом рачунара омогућавају измене параметара обликовања у реалном времену без заустављања производње. Ови системи могу компенсовати варијације у својствима материјала, дебљини или чврстоћи које би иначе довеле до размерних одступања. Могућност сталних прилагодби осигурава да геометрија цеви остане у оквиру спецификација упркос нормалним варијацијама у сировим материјалима.

Коначно димензионисање и калибрисање

Конечне димензије челичних цеви утврђују се преко операција прецизног димензионисања које се обављају након почетног формирања и заваривања. Калибрациони ваљци или матрице за димензионисање применом контролисаног притиска остварују тачне спољашње димензије, истовремено одржавајући једноликост дебљине зида. Ови делови се производе са веома малим толеранцијама и редовно се проверавају и замењују како би се одржала тачност димензија.

Хидраулични или серво-контролисани системи за димензионисање обезбеђују прецизну контролу сила димензионисања, осигуравајући конзистентне резултате у различитим условима материјала. Системи повратне спреге прате силе димензионисања и аутоматски подешавају параметре како би компенсовали варијације материјала или хабање алата. Ова затворена контура одржава димензионалну конзистентност током продужених серија производње.

Обеспећење квалитета и валидација процеса

Implementacija statističke kontrole procesa

Savremena proizvodnja čeličnih cevi u velikoj meri se oslanja na metode statističke kontrole procesa kako bi se održala preciznost tokom celokupne proizvodnje. Ovi sistemi prikupljaju ogromne količine podataka sa senzora postavljenih na različitim tačkama proizvodne linije, analizirajući trendove i varijacije koje mogu ukazivati na nastanak problema sa kvalitetom. Kontrolni dijagrami i statistički algoritmi prepoznaju kada procesi počinju da odstupaju od optimalnih parametara, pokrećući korektivne mere pre nego što dođe do proizvodnje neispravnih proizvoda.

Automatizovano prikupljanje podataka eliminira ljudske greške u nadzoru kvaliteta, pružajući istovremeno sveobuhvatnu dokumentaciju parametara proizvodnje za svaku proizvedenu cev. Ova praćivost omogućava proizvođačima da brzo identifikuju i isprave probleme u procesu, istovremeno pružajući kupcima detaljnu dokumentaciju o kvalitetu. Integracija podataka o kvalitetu sa sistemima planiranja proizvodnje optimizuje efikasnost proizvodnje uz održavanje visokih standarda preciznosti.

Trajno poboljšanje kroz analizu podataka

Напредне платформе за аналитику података обрађују податке о квалитету и производњи како би идентификовале могућности за побољшање прецизности и повећање ефикасности. Алгоритми машинског учења анализирају обрасце у подацима о производњи ради оптимизације параметара процеса и предвиђања потреба за одржавањем. Овакав аналитички приступ омогућава произвођачима да стално унапређују своје процесе, постижући све виши ниво прецизности и конзистентности.

Системи предиктивног одржавања прате стање и перформансе опреме како би спречили смањење прецизности услед хабања делова или неисправног поравнања. Решавањем питања одржавања пре него што утичу на квалитет производа, ови системи помажу у одржавању изузетне прецизности коју захтевају модерне примене. Редовни поступци калибрације и верификације осигуравају да системи мерења наставе да пружају тачне податке за контролу процеса.

Често постављана питања

Које су дозвољене отклоне које модерни алати за производњу челичних цеви могу да постигну?

Savremeni mašini za proizvodnju čeličnih cevi obično mogu postići dimenzione tolerancije od ±0,1 mm za spoljašnji prečnik i ±0,05 mm za debljinu zida u standardnoj proizvodnji. Napredni sistemi sa poboljšanim kontrolnim mogućnostima mogu postići još uži opseg tolerancija od ±0,05 mm za spoljašnji prečnik pri obradi visokokvalitetnih materijala u kontrolisanim uslovima. Ovi nivoi preciznosti održavaju se putem sofisticiranih kontrolnih sistema, komponenti izrađenih sa visokom preciznošću i kontinuiranog praćenja kvaliteta tokom celokupnog procesa proizvodnje.

Kako mašine za proizvodnju čeličnih cevi održavaju doslednost tokom dugih serija proizvodnje?

Постојаност током продужених серија производње одржава се кроз аутоматизоване системе контроле процеса који непрестано прате и подешавају параметре производње. Ови системи надокнађују хабање алата, варијације материјала и промене у спољашњој средини без људског умешања. Алгоритми статистичке контроле процеса откривају тенденције које могу указивати на развој проблема са квалитетом, док системи предиктивне одржавања спречавају постепено погоршање опреме које би могло утицати на прецизност. Редовна калибрација мерних система осигурава да се стандарди квалитета одржавају током читавог производног циклуса.

Коју улогу има припрема материјала у постизању прецизне производње цеви?

Припрема материјала је од суштинског значаја за производњу прецизних цеви, јер варијације у долазној челичној траци директно утичу на квалитет коначног производа. Системи за припрему ивица обезбеђују савршене ивице траке ради конзистентног заваривања, док опрема за исправљање уклања остатне напоне који би могли изазвати варијације у димензијама. Системи поравнања траке одржавају савршено централно вођење, а механизми за контролу напетости спречавају истегнуће или компресију током формирања. Ови кораци припреме стварају темељ за прецизну геометрију цеви и конзистентна механичка својства.

Како произвођачи проверавају прецизност својих машина за прављење челичних цеви?

Провера прецизности обухвата више поступака мерења и испитивања, укључујући контролу димензија калибрисаном мерном опремом, испитивање механичких карактеристика и неразарајуће испитивање заварених шавова. Машине за координатно мерење обезбеђују детаљну анализу димензија геометрије цеви, док статистичка анализа података из производње открива тенденције и варијације. Редовна калибрација свих мерних система осигурава тачност, а поређење са званичним референтним стандардима потврђује исправност мерења. Узорци из производње често се испитују у независним лабораторијама како би се потврдило да се прецизносни стандарди стално испуњавају.

Садржај

- Napredni kontrolni sistemi u savremenoj proizvodnji cevi

- Прецизно инжењерство у пројектовању машина

- Rukovanje materijalom i preciznost dovođenja

- Preciznost zavarivanja i kvalitet šava

- Контрола димензија током целокупне производне линије

- Обеспећење квалитета и валидација процеса

-

Често постављана питања

- Које су дозвољене отклоне које модерни алати за производњу челичних цеви могу да постигну?

- Kako mašine za proizvodnju čeličnih cevi održavaju doslednost tokom dugih serija proizvodnje?

- Коју улогу има припрема материјала у постизању прецизне производње цеви?

- Како произвођачи проверавају прецизност својих машина за прављење челичних цеви?