madaling maintayn na makinang gumagawa ng gi pipe

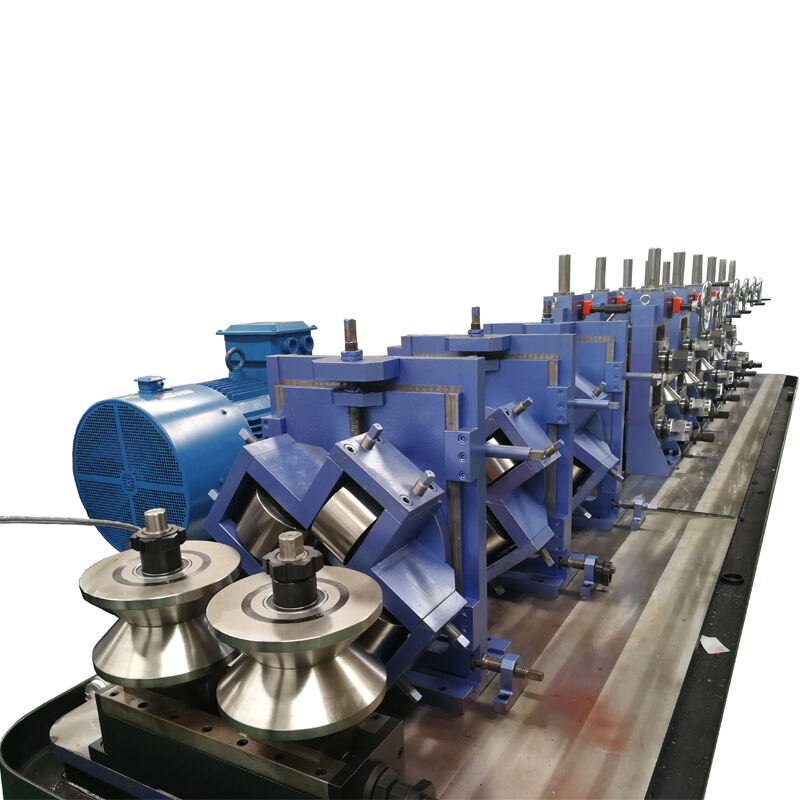

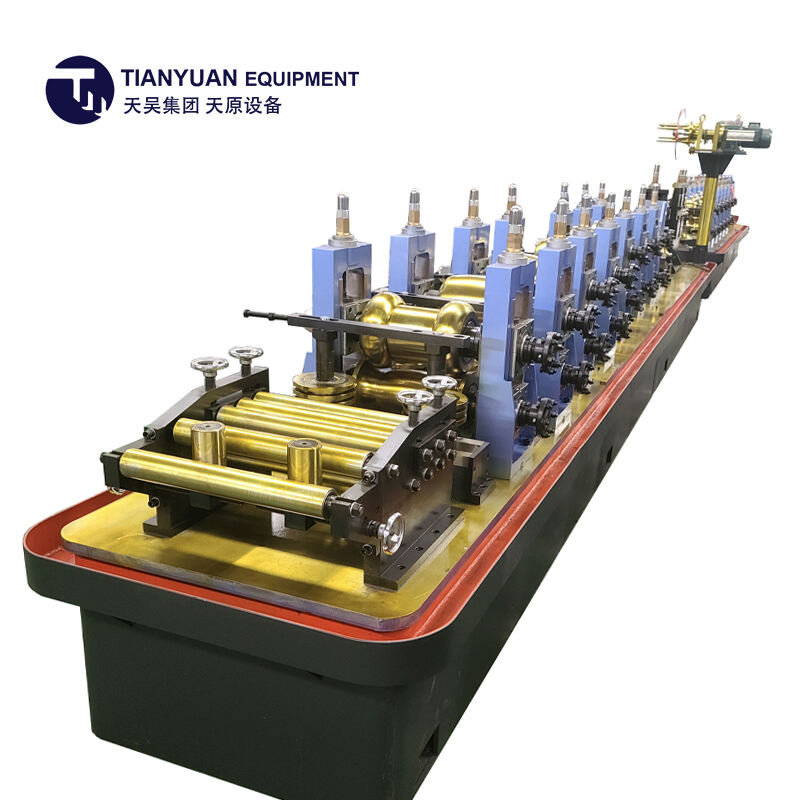

Ang madaling mai-maintain na GI pipe making machine ay nagrerepresenta ng isang malaking pag-unlad sa teknolohiya ng paggawa ng tube. Ang sofistikadong aparato na ito ay disenyo upang magproducce ng mataas kwalidad na mga galvanized iron pipes nang mabilis at konsistente. Nagkakaisa ang makamit na forming technology sa automated control systems, pagpapahintulot ng presisyong dimensional accuracy at masusing katatagan ng sipag. Mayroon itong malakas na frame construction, advanced roll forming stations, at isang user-friendly control panel na nagbibigay-daan sa mga operator na ayusin ang mga parameter nang madali. Kasama sa proseso ng forming ng makina ang maraming stage: uncoiling, leveling, forming, welding, cooling, sizing, at cutting. Bawat stage ay optimisado para sa maximum efficiency habang pinapanatili ang kwalidad ng produkto. Sumasama sa sistema ang automatic tracking at correction mechanisms upang siguruhin ang tuwirang produksyon ng tube at konsistente na kalakasan ng wall. Mga napapanahong teknolohikal na karakteristikang ito ay patnubayan digital thickness control, automated welding monitoring, at real-time quality inspection systems. Partikular na bunga ang makina sa paggawa ng konstruksyon, infrastructure development, at industrial applications, maaaring magproducce ng mga tube na mula 15mm hanggang 100mm sa diameter. Sa pamamagitan ng advanced PLC control system, matatag na operasyon at presisyong kontrol ng parameter ang resulta, nagdadala ng mga tube na nakakamit ang internasyonal na estandar ng kwalidad.