mabuting pipa ng carbon steel na makukuhang sa China

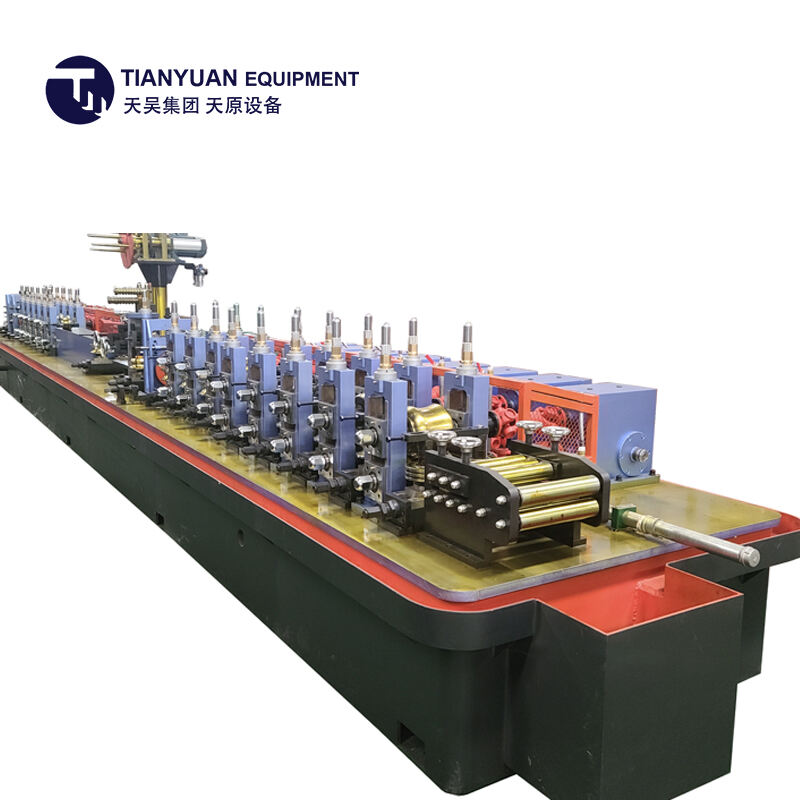

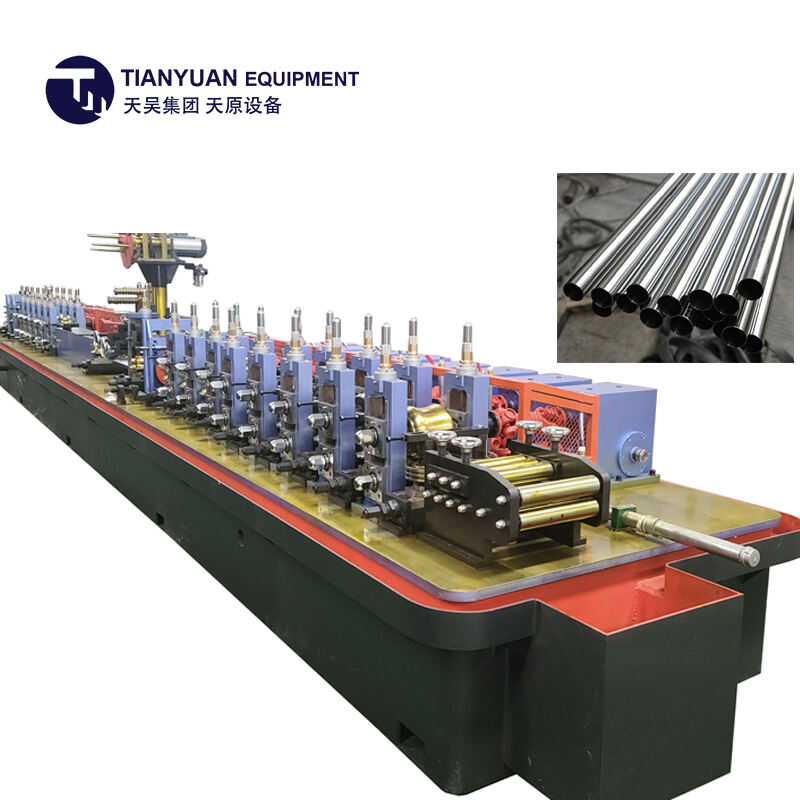

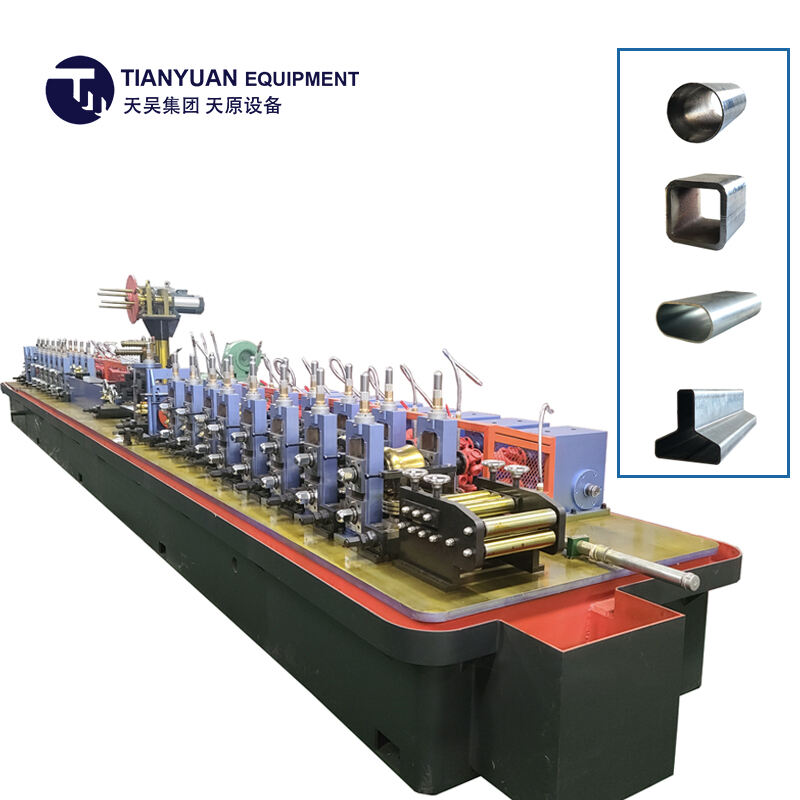

Ang maaaring makabuo ng mga tube na carbon steel na may mataas na produktibidad ay isang pinakamahusay na solusyon sa paggawa na disenyo para sa paggawa ng mga kwalidad na mataas na carbon steel pipes na may katatagan at konsistensya. Ang masunod na makina ay nag-iintegrate ng maraming etapa ng produksyon, kabilang ang pagsuporta ng material, porma, pagtutulak, pagsukat, at proseso ng pag-cut, lahat sa loob ng isang sistema ng streamlined na sistemang ito. Gumagamit ang makina ng napakahusay na teknolohiya ng porma na nagpapatakbo ng parehong kapal na pader at masusing integridad ng estraktura ng tapos na mga pipe. Ang kanyang kontrol na sistemang automatiko ay nagpapanatili ng matapat na aklatuhan ng sukat sa buong proseso ng produksyon, habang ang teknolohiya ng high-frequency welding ay nagpapakita ng malakas at tiyak na butas na butas. Maaaring handaan ng makina ang iba't ibang mga espesipikasyon ng pipe, karaniwan ang paggawa ng mga pipe mula 20mm hanggang 219mm sa diyametro, na may mga kapal na mula 1.2mm hanggang 6mm. Itinayo sa pamamagitan ng komponenteng pang-industriya, ang sistemang ito ay may higit na maingat na monitoring na sistemang patuloy na nag-aasess ng mga parameter ng produksyon, kabilang ang temperatura, presyon, at kalidad ng pagtutulak. Ang kaya ng makina ay nagbibigay-daan sa mabilis na pagbabago ng espesipikasyon, gumagawa ito upang ideal para sa mass production at mga pangangailangan ng paggawa na custom. Ang kanilang pinagalingan na mekanismo ng produktibidad ay nagreresulta sa minimum na basura ng material at bawasan ang paggamit ng enerhiya, samantalang nakikipagpatuloy sa konsistente na antas ng kwalidad ng output. Nakikitang madalas na gamit ang equipamento sa mga industriya tulad ng konstruksyon, transportasyon ng langis at gas, mechanical engineering, at mga aplikasyon ng estraktura, kung saan ang mga kwalidad na mataas na carbon steel pipes ay pangunahing bahagi.