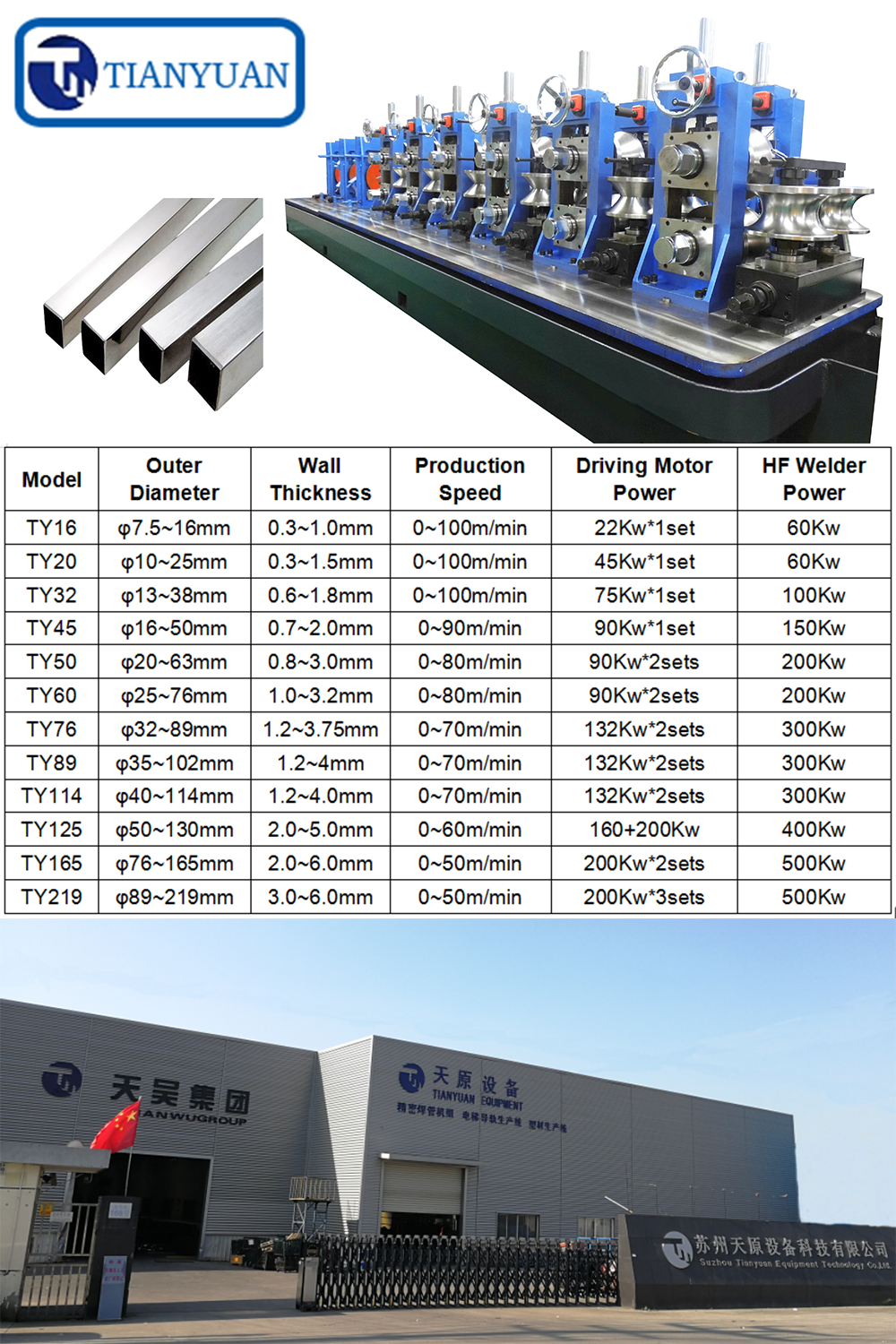

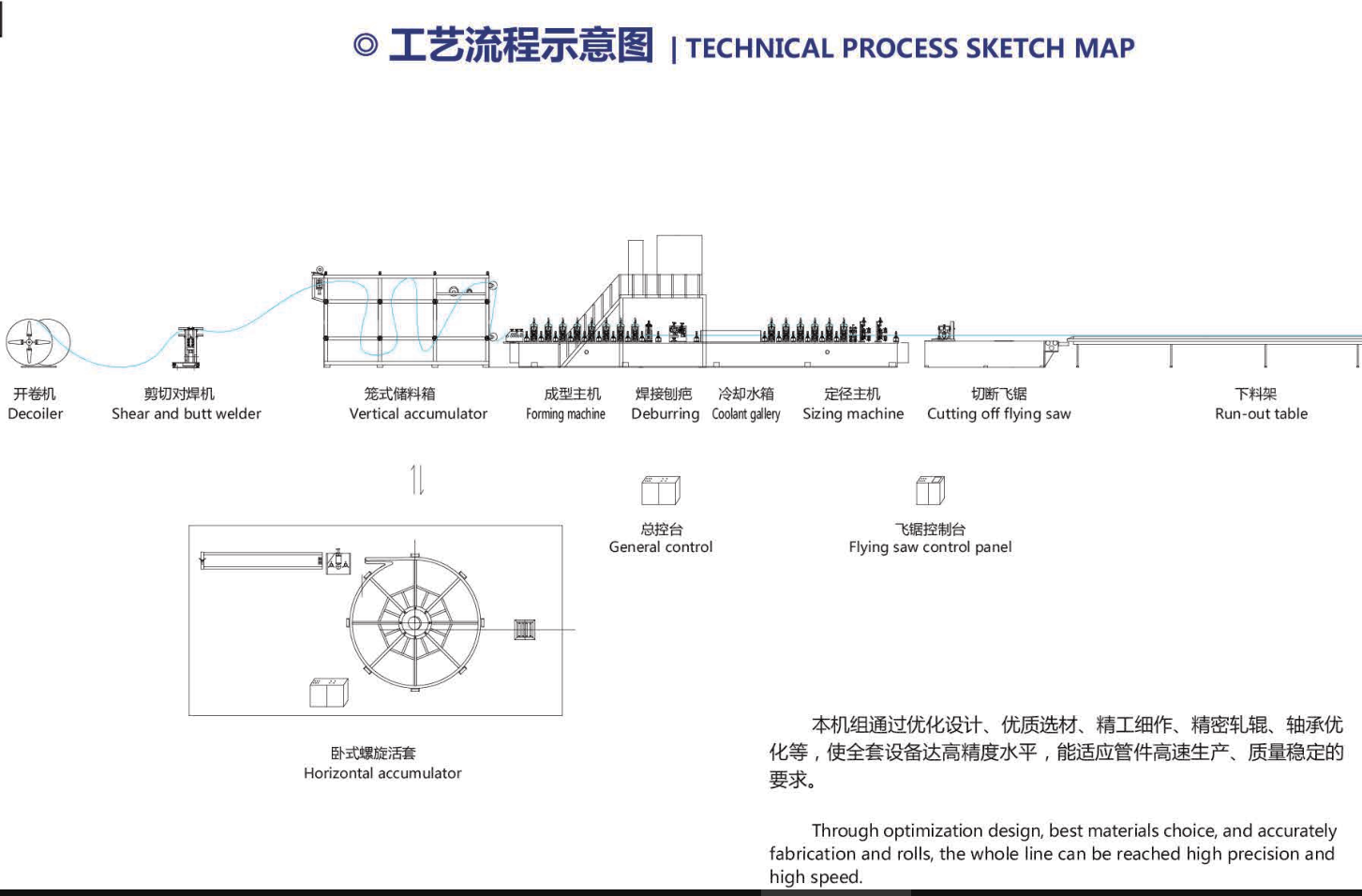

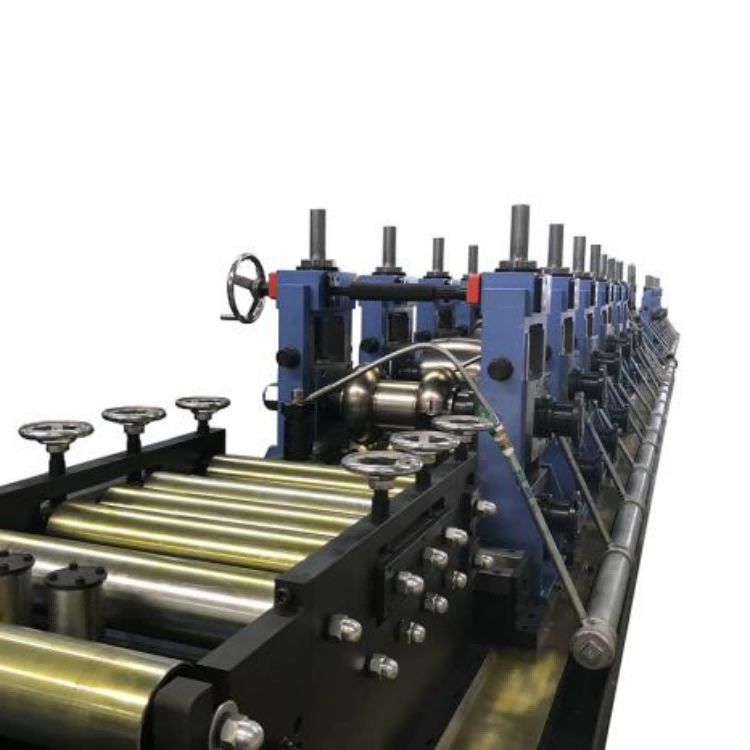

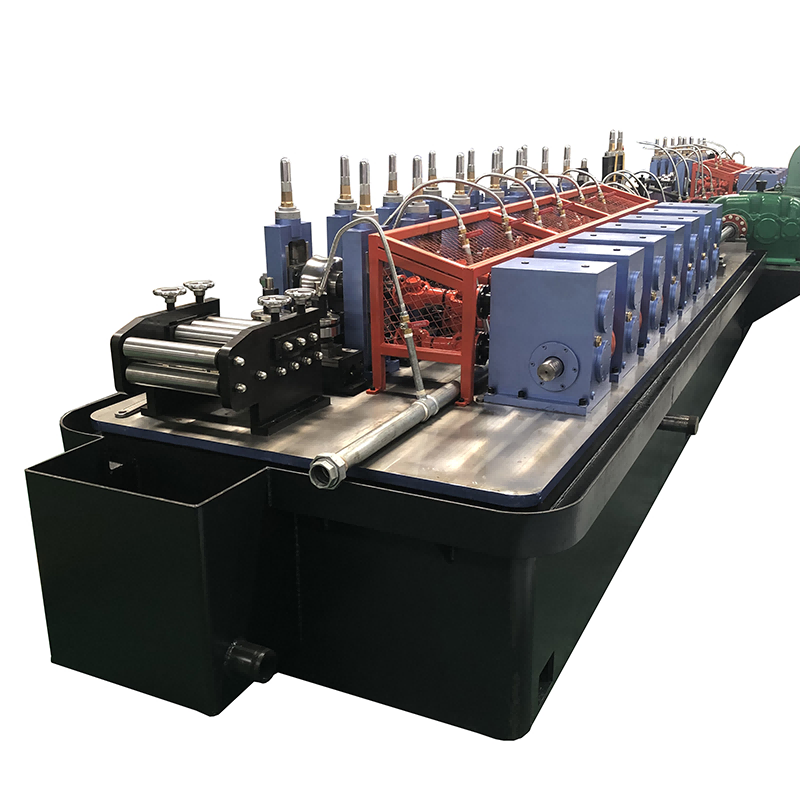

This high-frequency welding pipe mill is specialized equipment to produce high frequency straight seam welded pipes for structural pipe and industrial pipe withΦ76~Φ165mm and wall thickness of 2.0~6.0mm. Through optimization design, best materials choice, and accurately fabrication and rolls, the whole line can be reached high precision and high speed. Within suitable range of pipe diameter and wall thickness, pipe production speed can be adjusted.

Place of Origin: |

China |

Brand Name: |

Tian Yuan |

Model Number: |

TY165 |

Certification: |

CE |

2. Product commercial terms

Minimum Order Quantity: |

1 |

Price: |

560000USD |

Packaging Details: |

Case |

Delivery Time: |

90days |

Payment Terms: |

T/T、L/C |

Supply Ability: |

10sets |

3. Product introduction

Quick Detail:

Tube Mill、Pipe Making Machine、Pipe Production Line

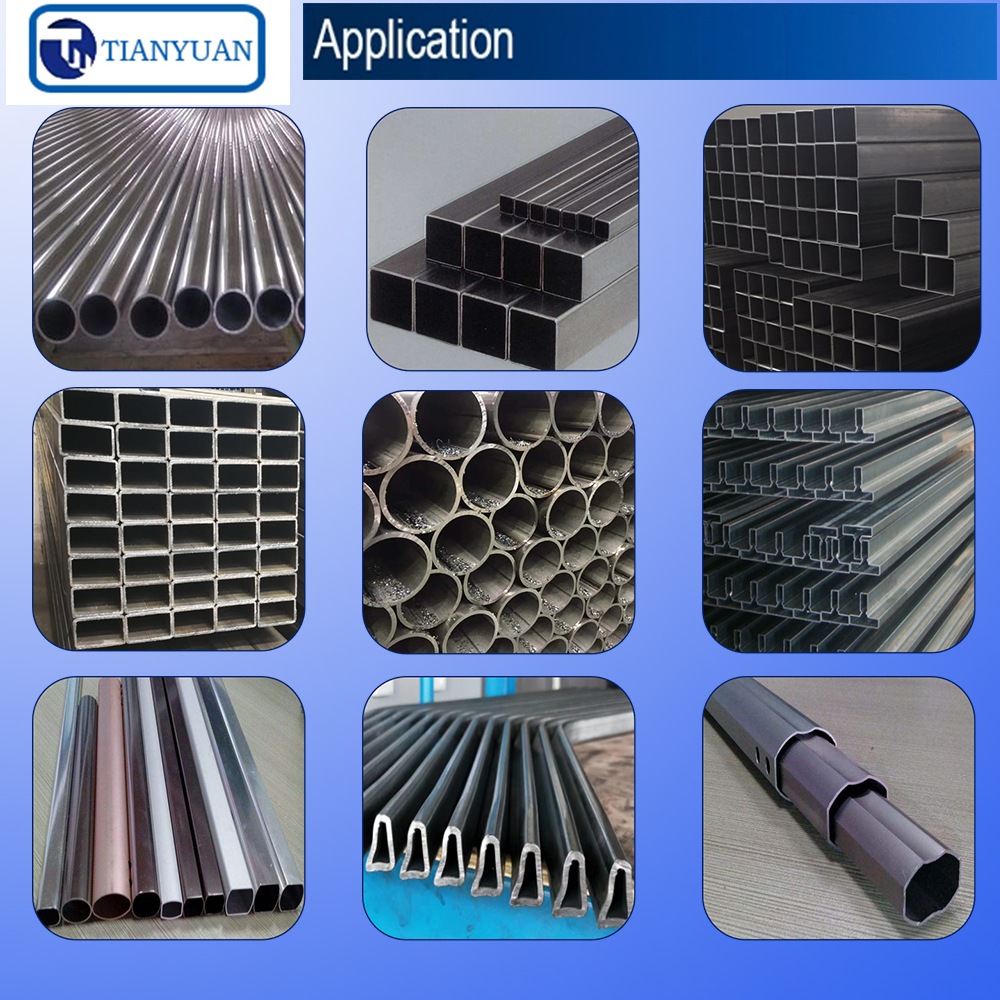

Applications:

Electric heating tube, fridge pipe, Auto car pipe, sporting facility tube, furniture pipe, cooler pipe, pressure feeding pipe, construction pipe, configuration pipe.

Specifications:

|

Size |

Thickness |

Round pipe |

Φ76mm~Φ165mm |

2.0mm~6.0mm |

Square pipe |

60×60mm~130×130mm |

2.0mm~5.0mm |

Rectangle pipe |

40×80mm~80×160mm |

2.0mm~5.0mm (a:b≤2:1) |

Competitive Advantage:

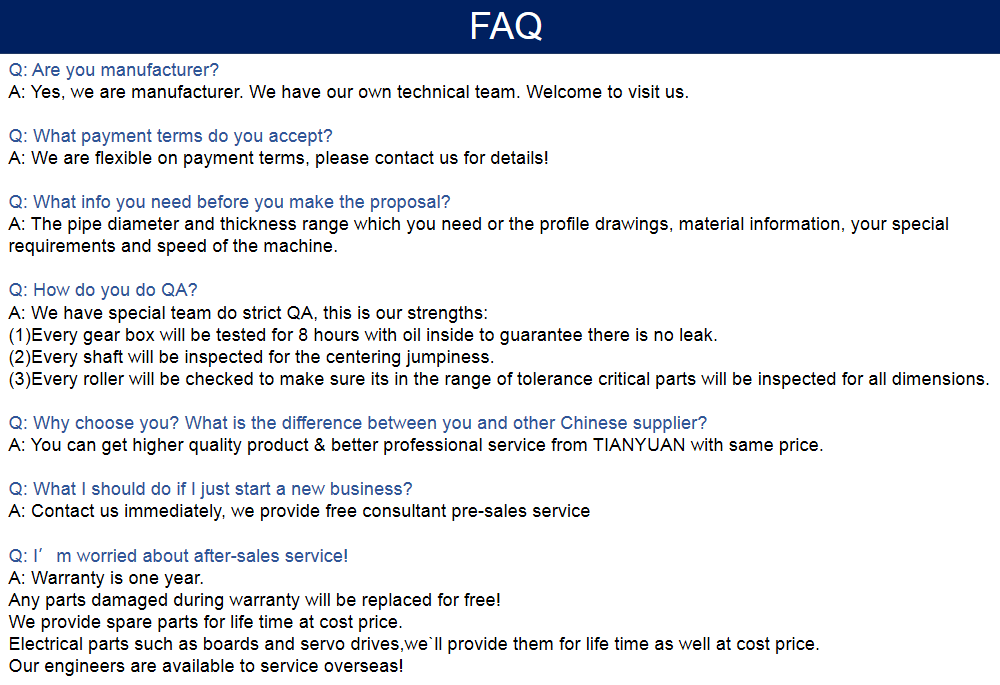

1.After-sales service :our after-sales service team have profound expertise and onsite experience. From equipment installation and commissioning to training and solving daily problems, the team provides excellent services to reassure customers and save their trouble

2.Inspection before installation: we will check every part of the line and test machine operation to make sure it works well so you need not take much time to adjust when the machine arrive in your factory.

3.Stand : our stands one-step pouring they are high tensile and high stability

4.The run out coefficient of rollers just 1~2 silk

5.Gearbox will test 4 hour at least about the oil leakage ,fever, and noise to insure they work well

6.The machine tool was made by numerical control machine straightly the precision of key and groove are very high

7.The fly saw machine tool can reduce noise and very stable

8.Adjustment of whole line just need two wrench the specifications are unified

Tag:

High Quality、High Precision、Easy to Operate、Factory Export、China Supplier

4.Technical process sketch map of Suzhou Tianyuan Pipe Making Line.

5.Parts options for Suzhou Tianyuan pipe mill.

6.Company information

Suzhou Tianyuan Equipment Technology Co., Ltd is located in Foho Developing Zone, Wu Jiang district, Suzhou City, Jiangsu Province close to Shanghai.

Our company specialized in researching and manufacturing Precision High Frequency Welded tube production line, roll forming production line, elevator guider production line and SS ARC tube production line etc.

The main products of company including Precision High Frequency Welding Pipe Mill, Cold Roll Forming Machine, Cable tray roll forming machine, highway guardrail roll forming machine, steel shelf roll forming machine, scaffold panel roll forming machine, C channel roll forming machine and Elevator Hollow Guide Rail Forming Machine. We developed and designed Elevator hollow guide rail forming machine, High speed shape steel roll forming machine, Automatic shearing & butt welding machine are leading the industry.

At present, the sales network of company is covering Southeast Asia and Middle East. We have office or agent in Vietnam, Thailand, Indonesia, Malaysia, India, and Eastern Europe. Under the principles of leading technology, trusty quality, excellent service, company becomes one of most competitive one in the Industry step by step.

7.Packing and Shopping

8.FAQ

TY76 Construction Industry High Precision And Square ERW Tube Making Machine

TY32 Perfect After-Sales Service Square Galvanized Steel Pipe Line Machine

TY125 Factory Export High Quality And Precision ERW Tube Welding Machine

TY50 High Precision Factory Export Erw Tube Mill With Engineer Site Service