The manufacturing industry continues to evolve with advanced machinery that delivers precision, efficiency, and reliability. Among the most critical equipment in metal fabrication is the ms tube making machine, which plays a pivotal role in producing medium-strength pipes for various industrial applications. These sophisticated machines have revolutionized how manufacturers approach tube production, offering enhanced control over dimensions, material properties, and production speeds. Modern facilities rely on these systems to meet growing demands for quality steel tubes in construction, automotive, and infrastructure projects.

The technological advancement in tube manufacturing has led to significant improvements in production capabilities and output quality. Industrial operators now have access to machines that can process various grades of mild steel with remarkable consistency. The integration of automated systems ensures that each tube meets stringent quality standards while maintaining cost-effectiveness. This technological evolution has made it possible for manufacturers to compete effectively in global markets while reducing waste and optimizing resource utilization.

Understanding MS Tube Manufacturing Technology

Core Components and Functionality

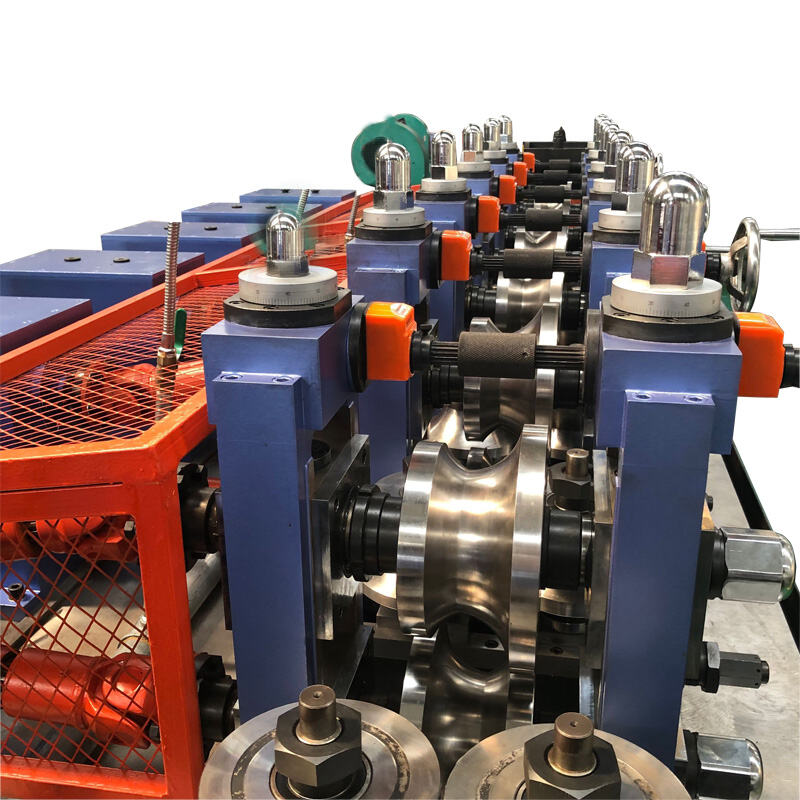

An ms tube making machine incorporates several essential components that work in harmony to transform flat steel strips into precision tubes. The uncoiling system feeds raw material consistently, while the forming section gradually shapes the steel into the desired circular or square profile. High-frequency welding units create strong, continuous seams that ensure structural integrity throughout the tube length. Temperature control systems maintain optimal welding conditions, preventing material degradation and ensuring uniform joint strength.

The sizing and calibrating mechanisms within these machines ensure dimensional accuracy across the entire production run. Advanced control systems monitor various parameters including welding temperature, feed rate, and forming pressure to maintain consistent quality. Modern machines feature sophisticated sensors that detect variations in material thickness and automatically adjust processing parameters. This level of automation reduces operator intervention while improving overall production reliability and efficiency.

Material Processing Capabilities

Contemporary ms tube making machine designs accommodate a wide range of mild steel grades and thicknesses. The machines can process materials ranging from 0.5mm to 6mm thickness, depending on the specific model and configuration. Different steel compositions require varying processing parameters, and modern machines automatically adjust welding power, forming speed, and cooling rates based on material specifications. This versatility allows manufacturers to produce tubes for diverse applications without requiring multiple specialized machines.

Quality control systems integrated into these machines continuously monitor material properties during processing. Advanced metallurgical sensors detect variations in carbon content, tensile strength, and surface condition, enabling real-time adjustments to maintain consistent output quality. The ability to handle various material grades efficiently makes these machines valuable investments for facilities serving multiple market segments.

Production Efficiency and Output Quality

Speed and Throughput Optimization

Modern ms tube making machine configurations achieve impressive production speeds while maintaining exceptional quality standards. High-end models can produce tubes at rates exceeding 120 meters per minute, depending on diameter and wall thickness specifications. The key to achieving these speeds lies in the precise coordination of all machine components, from material feeding through final sizing operations. Advanced control algorithms optimize acceleration and deceleration cycles to minimize stress on both the machinery and processed materials.

Production planning software integrated with these machines enables operators to schedule runs efficiently, minimizing changeover times between different tube specifications. Automated tool changing systems reduce setup times significantly, allowing facilities to respond quickly to customer requirements. The combination of high-speed processing and rapid changeover capabilities makes these machines ideal for both large-volume production and custom manufacturing applications.

Quality Assurance Systems

Quality control in modern tube manufacturing extends far beyond basic dimensional checking. Integrated quality systems in an ms tube making machine monitor weld quality, surface finish, and mechanical properties continuously throughout production. Non-destructive testing methods, including ultrasonic and eddy current inspection, detect potential defects before tubes leave the production line. This proactive approach prevents defective products from reaching customers and reduces warranty claims.

Statistical process control systems collect and analyze production data to identify trends and potential issues before they affect product quality. These systems generate detailed reports that help operators optimize machine settings and maintenance schedules. The implementation of Industry 4.0 principles allows remote monitoring and diagnostics, enabling predictive maintenance strategies that minimize unplanned downtime.

Applications and Market Segments

Construction and Infrastructure Projects

The construction industry represents one of the largest markets for tubes produced by ms tube making machine equipment. Medium-strength pipes find extensive use in structural applications including building frames, scaffolding systems, and architectural features. The consistent quality and dimensional accuracy achieved by modern tube manufacturing machines ensure that these products meet strict building codes and engineering specifications. Construction projects require reliable supply chains, and efficient tube production helps meet demanding project timelines.

Infrastructure development projects worldwide continue driving demand for quality steel tubes. Water distribution systems, gas pipelines, and electrical conduit applications all rely on precisely manufactured tubes. The corrosion resistance and mechanical properties of tubes produced on modern equipment make them suitable for long-term infrastructure installations. Municipal projects increasingly specify tubes manufactured using advanced production methods due to their superior consistency and reliability.

Automotive and Transportation Industries

Automotive manufacturers utilize tubes produced by advanced ms tube making machine systems for various vehicle components. Chassis construction, exhaust systems, and roll cage fabrication all require tubes with specific mechanical properties and dimensional tolerances. The automotive industry's emphasis on weight reduction while maintaining strength makes precision-manufactured tubes increasingly important. Advanced tube manufacturing capabilities enable the production of complex profiles that optimize material usage without compromising performance.

Commercial vehicle manufacturers particularly benefit from the consistency and reliability of modern tube production methods. Heavy-duty applications require tubes that can withstand significant stress while maintaining dimensional stability over extended service periods. The traceability features of modern manufacturing systems also support automotive quality requirements, providing detailed documentation of material properties and processing parameters for each production lot.

Economic Benefits and Cost Considerations

Investment Return Analysis

The investment in a modern ms tube making machine requires careful financial analysis considering both immediate costs and long-term benefits. Initial capital expenditure includes not only the machine cost but also installation, training, and facility modifications. However, the efficiency gains and quality improvements typically provide attractive returns within two to three years. Reduced labor requirements, lower defect rates, and increased production speeds contribute significantly to improved profitability.

Energy efficiency improvements in modern machines also contribute to operational cost reductions. Advanced control systems optimize power consumption during different production phases, reducing electricity costs compared to older equipment. Maintenance costs decrease due to improved component reliability and predictive maintenance capabilities. These operational savings accumulate over the machine's service life, enhancing the overall return on investment.

Market Competitiveness Factors

Companies utilizing advanced ms tube making machine technology gain significant competitive advantages in their markets. The ability to produce high-quality tubes consistently while maintaining competitive pricing attracts and retains customers. Shorter lead times enabled by efficient production systems allow manufacturers to respond quickly to market opportunities. Quality certifications become easier to maintain when using reliable, well-controlled manufacturing processes.

Export market opportunities expand when manufacturers can demonstrate consistent quality and reliable delivery capabilities. International customers increasingly require suppliers who can provide detailed quality documentation and trace ability throughout the production process. Modern tube manufacturing equipment facilitates compliance with various international standards, opening doors to global market participation.

Technology Trends and Future Developments

Automation and Digital Integration

The evolution toward fully automated ms tube making machine systems continues accelerating as manufacturers seek to improve efficiency and reduce labor dependency. Artificial intelligence integration enables predictive adjustments based on material variations and environmental conditions. Machine learning algorithms analyze production data to optimize processing parameters automatically, reducing the need for manual intervention. These technological advances promise further improvements in both productivity and product quality.

Digital twin technology allows virtual monitoring and optimization of tube manufacturing processes. Operators can simulate different production scenarios and optimize settings before implementing changes on actual equipment. Remote monitoring capabilities enable expert technicians to provide support and diagnostics from distant locations, reducing service costs and minimizing downtime. Cloud-based data storage and analysis provide insights that help manufacturers continuously improve their operations.

Environmental Sustainability Initiatives

Modern ms tube making machine designs increasingly emphasize environmental responsibility through improved energy efficiency and waste reduction. Advanced heating systems recover and reuse thermal energy, reducing overall power consumption. Precision forming techniques minimize material waste by achieving target dimensions with minimal trimming or rework. These environmental improvements also contribute to cost reductions while supporting corporate sustainability goals.

Recycling capabilities built into modern tube manufacturing systems enable the processing of recycled steel materials without compromising product quality. This capability becomes increasingly important as environmental regulations tighten and customers demand sustainable manufacturing practices. The ability to demonstrate environmental responsibility through advanced manufacturing practices provides additional competitive advantages in environmentally conscious markets.

FAQ

What factors should be considered when selecting an ms tube making machine

When selecting an ms tube making machine, consider production capacity requirements, material thickness range, tube diameter specifications, and quality control features. Evaluate the manufacturer's service support network, spare parts availability, and operator training programs. Energy efficiency, automation level, and integration capabilities with existing production systems are also crucial factors. Additionally, assess the machine's flexibility to handle different tube specifications and future expansion possibilities.

How does maintenance impact the performance of tube making equipment

Regular maintenance significantly affects both the performance and longevity of ms tube making machine equipment. Preventive maintenance programs help identify potential issues before they cause production disruptions or quality problems. Proper lubrication, component inspection, and calibration ensure consistent output quality and extend equipment life. Modern machines provide diagnostic capabilities that facilitate condition-based maintenance strategies, optimizing maintenance schedules while minimizing costs.

What quality standards apply to tubes produced by these machines

Tubes produced by ms tube making machine equipment must comply with various national and international standards depending on their intended applications. Common standards include ASTM, EN, JIS, and GB specifications covering dimensional tolerances, mechanical properties, and surface quality requirements. Construction applications may require additional certifications for structural adequacy, while automotive applications demand specific material traceability and testing documentation. Modern manufacturing systems facilitate compliance with multiple standards simultaneously.

How can manufacturers optimize production efficiency with tube making machines

Manufacturers can optimize production efficiency by implementing comprehensive production planning systems that minimize changeover times between different tube specifications. Proper operator training ensures machines operate at optimal parameters consistently. Regular performance monitoring and data analysis help identify opportunities for process improvements. Investing in automated material handling systems reduces manual intervention and improves overall workflow efficiency. Additionally, maintaining adequate spare parts inventory prevents extended downtime during maintenance activities.