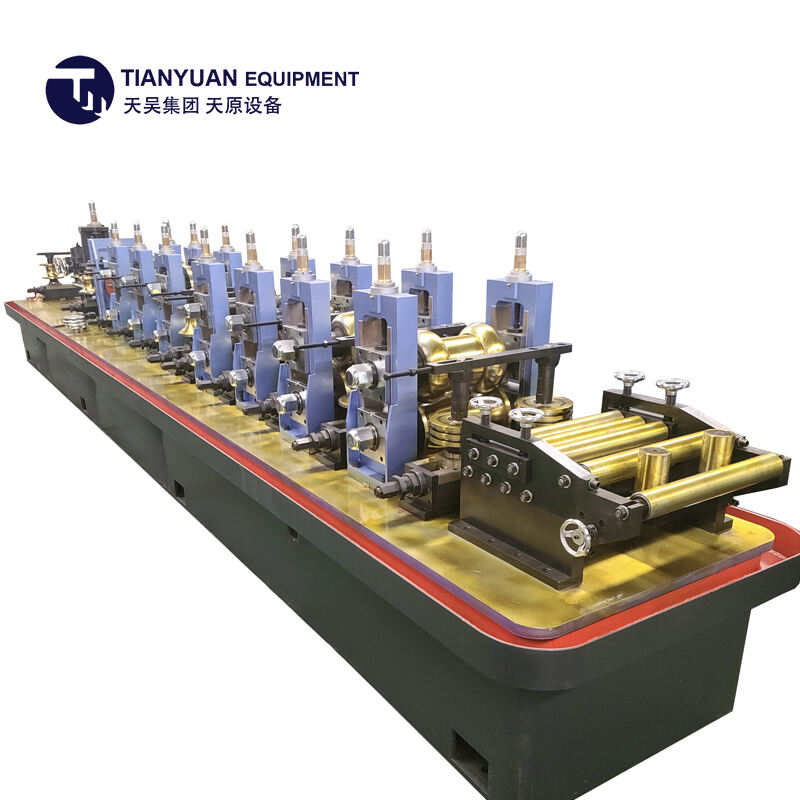

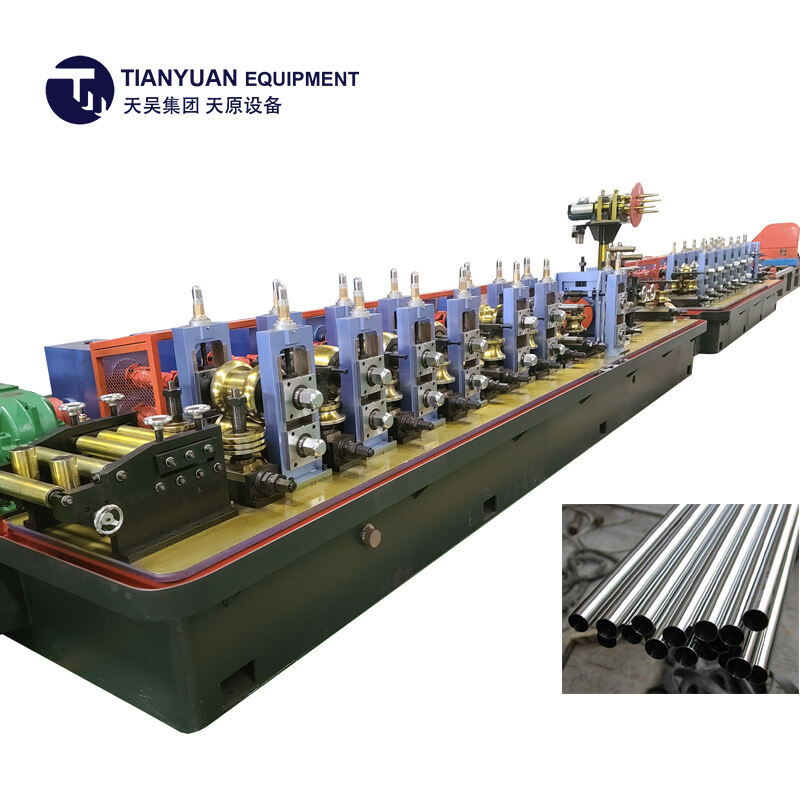

nhà máy máy hàn ống HF

Nhà máy ống thép hàn HF đại diện cho một cơ sở sản xuất hiện đại hàng đầu, chuyên sản xuất các ống thép hàn tần số cao với độ chính xác và hiệu quả. Cơ sở tiên tiến này tích hợp công nghệ mới nhất cho phép sản xuất liên tục các ống hàn thông qua quy trình phức tạp bao gồm tạo hình dải thép, hàn tần số cao và xử lý sau khi hàn. Nhà máy sử dụng hệ thống tự động hóa và các hoạt động được kiểm soát bằng máy tính để duy trì chất lượng ổn định trên toàn bộ dây chuyền sản xuất. Với cấu trúc toàn diện, cơ sở quản lý mọi thứ từ việc xử lý nguyên liệu thô đến kiểm tra sản phẩm cuối cùng, đảm bảo mỗi ống đạt tiêu chuẩn ngành nghiêm ngặt. Quy trình sản xuất bắt đầu bằng việc xử lý dải thép, tiếp theo là các hoạt động tạo hình chính xác để tạo ra hình dạng ống. Trạm hàn tần số cao, là trái tim của hoạt động, sử dụng cảm ứng điện từ để tạo ra các mối hàn mạnh mẽ, đáng tin cậy ở tốc độ ấn tượng. Các trạm kiểm soát chất lượng được trang bị thiết bị thử nghiệm tiên tiến, bao gồm hệ thống thử nghiệm siêu âm và dòng điện Foucault, để xác minh độ bền của mỗi mối hàn. Nhà máy cũng có thiết bị điều chỉnh và làm thẳng chuyên dụng, cùng với hệ thống cắt đảm bảo các thông số chiều dài chính xác. Giải pháp đóng gói và lưu trữ hiện đại hoàn thành chu kỳ sản xuất, chuẩn bị các ống thép đã hoàn thiện để vận chuyển an toàn đến khách hàng trên toàn thế giới.