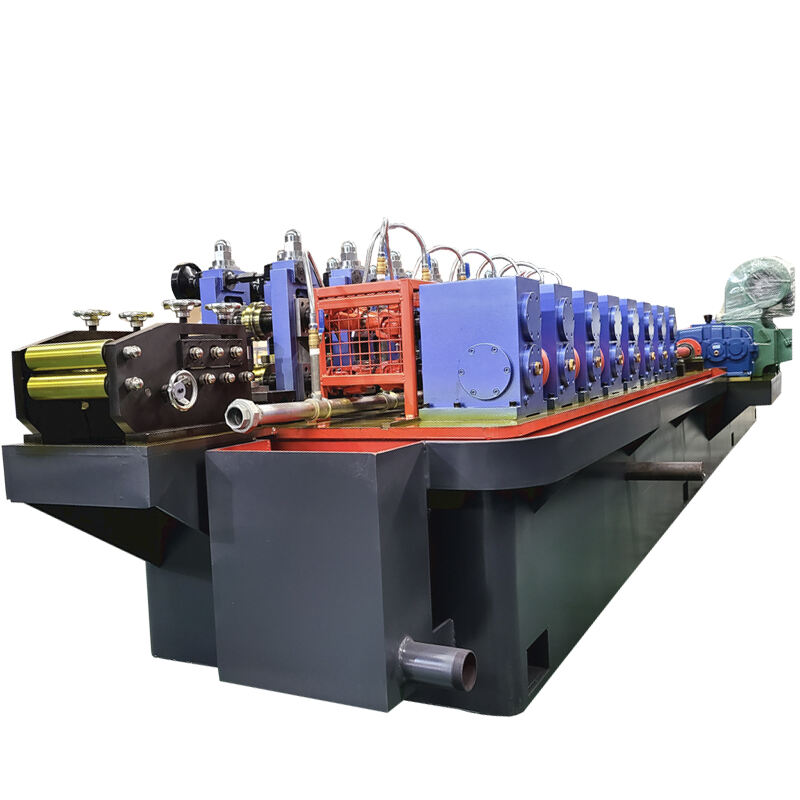

geavanceerde stael buis maakmasjien

Die gevorderde staelbuyskepingsmasjiene verteenwoordig 'n snitskootoplossing in moderne vervaardiging, deur presisie-ingenieurswese met outomatiseerde produksiekragte te integreer. Hierdie sofistikeerde toerusting verander rowe staelmateriaal in hoë-kwaliteitsbuise deur 'n nougekoördineerde proses van vorming, skwepering en afwerking. Die masjiene maak gebruik van gevorderde kouroltechnologie, wat die produksie van buise met verskillende diameter en muurdigtes moontlik maak om verskeie industriële spesifikasies te voldoen. Sy intelligente beheersisteem verseker konsekwente kwaliteit deur die hele produksieproses heen, terwyl dit kritieke parameters soos temperatuur, druk en materiaalvloei monitoor. Die masjiene het meerdere verwerkingsstasies, insluitend materiaalloading, vorming, skwepering, grootteaanpassing en snyeenhede, alles wat in gesinchroniseerde harmonie werk. Met produksiespoed wat op tot 120 meter per minuut kan bereik word, verbeter dit beduidend vervaardigingsdoeltreffendheid terwyl presiese dimensieakkuraatheid behou word. Die stelsel se veerkragtigheid laat toe dat sowel rond as vierkantige buise geproduseer word, wat dit geskik maak vir toepassings in die bou-, motor-, energie- en infrastruktuursektore. Gevorderde sensors en kwaliteitsbeheermechanismes monitoor die produksieproses voortdurend, versekerend dat elke buis streng industriele standaarde en spesifikasies voldoen.