prys van gi-buismaakmasjien

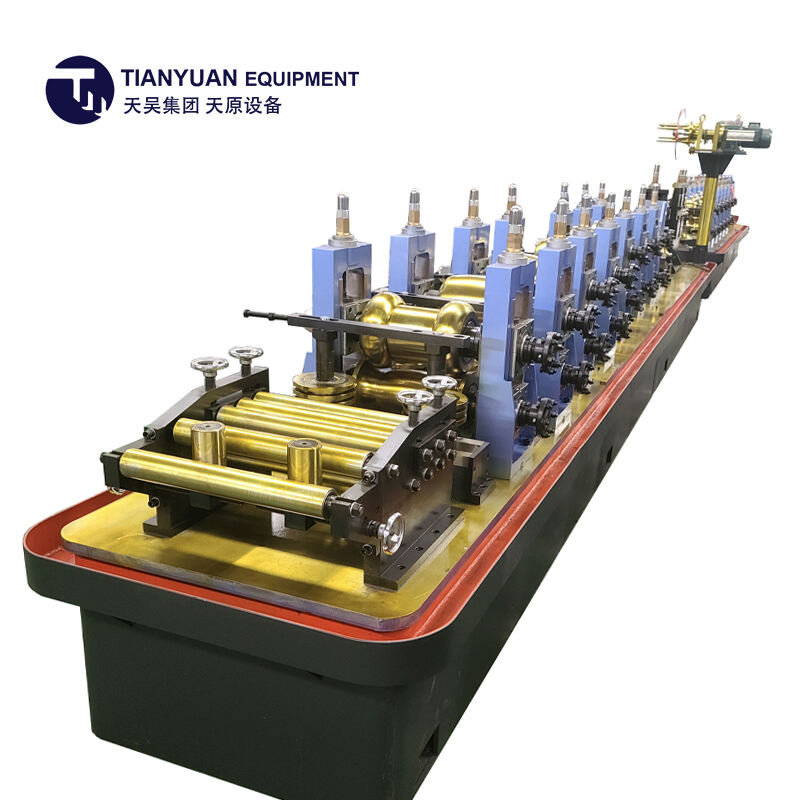

Die prys van die GI-pyp maakmasjien verteenwoordig 'n kritieke oorweging vir vervaardigers wat strewe om hul pypproduksiekapasiteite te stel op of te verbeter. Hierdie gevorderde toerusting, ontwerp vir die produksie van galvaniseerde ysterpype, kom saam met verskillende pryse afhangende van spesifikasies, kapasiteit en tegnologiese kenmerke. Moderne GI-pyp maakmasjiene sluit gewoonlik outomatiseringbeheersisteme, presisie-snymekanisme en hoëkwaliteit swartstasies in. Die prysreeks kan aansienlik wissel, van inkomingsvlakmodelle wat ongeveer $50,000 begin tot sofwatige stelsels wat $200,000 oorskry. Hierdie masjiene het gevorderde vormingstegnologie wat konsekwente pypdeursnee en wanddikte verseker, terwyl dit hoë produksiespoed van tot 80 meter per minuut onderhou. Die prysstruktuur weerspieël dikwels addisionele komponente soos dekonsolstelsels, regstellingsenhede, formateringsstasies en kwaliteitsbeheersisteme. Vervaardigers moet faktore soos produksiekapasiteitsvereistes, pypdeursnee-rente en automatiseringvlakke oorweeg wanneer hulle masjienepryse evalueer. Meeste moderne eenhede sluit PLC-beheersisteme, raakskaarinterfaces en reële tyd-toepassingsvermoëns in, wat die algemene koste beïnvloed, maar bydra tot verbeterde doeltreffendheid en produk-kwaliteit.