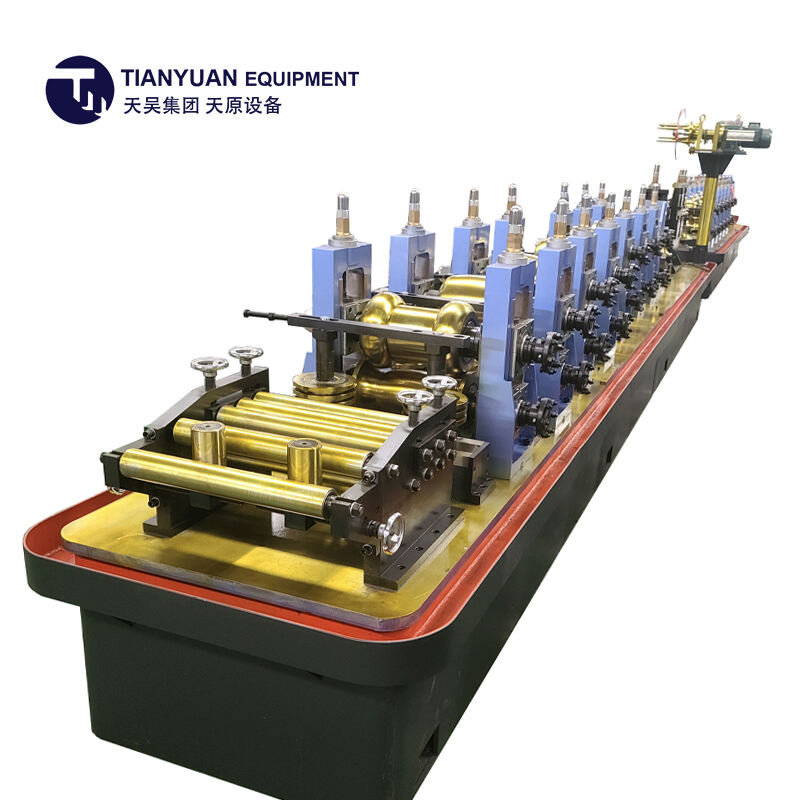

safe gi pipe making machine

The safe GI pipe making machine represents a significant advancement in pipe manufacturing technology, offering a comprehensive solution for producing high-quality galvanized iron pipes. This sophisticated equipment integrates multiple production stages, from material feeding to final pipe formation, ensuring consistent quality and operational safety. The machine employs advanced forming technology with precise roll design that guarantees uniform wall thickness and excellent surface finish. It features an automated control system that monitors critical parameters such as temperature, pressure, and speed throughout the production process. The machine can handle various pipe specifications, typically producing pipes ranging from 1/2 inch to 4 inches in diameter, with wall thicknesses from 1.5mm to 4mm. Its production line includes essential components such as an uncoiler, forming section, welding unit, cooling system, and cutting mechanism. The integration of safety features, including emergency stop systems and protective guards, ensures operator safety while maintaining high production efficiency. This machine is particularly valuable in construction, infrastructure development, and industrial applications where reliable galvanized pipes are essential.