automobile pipe making machine quotation

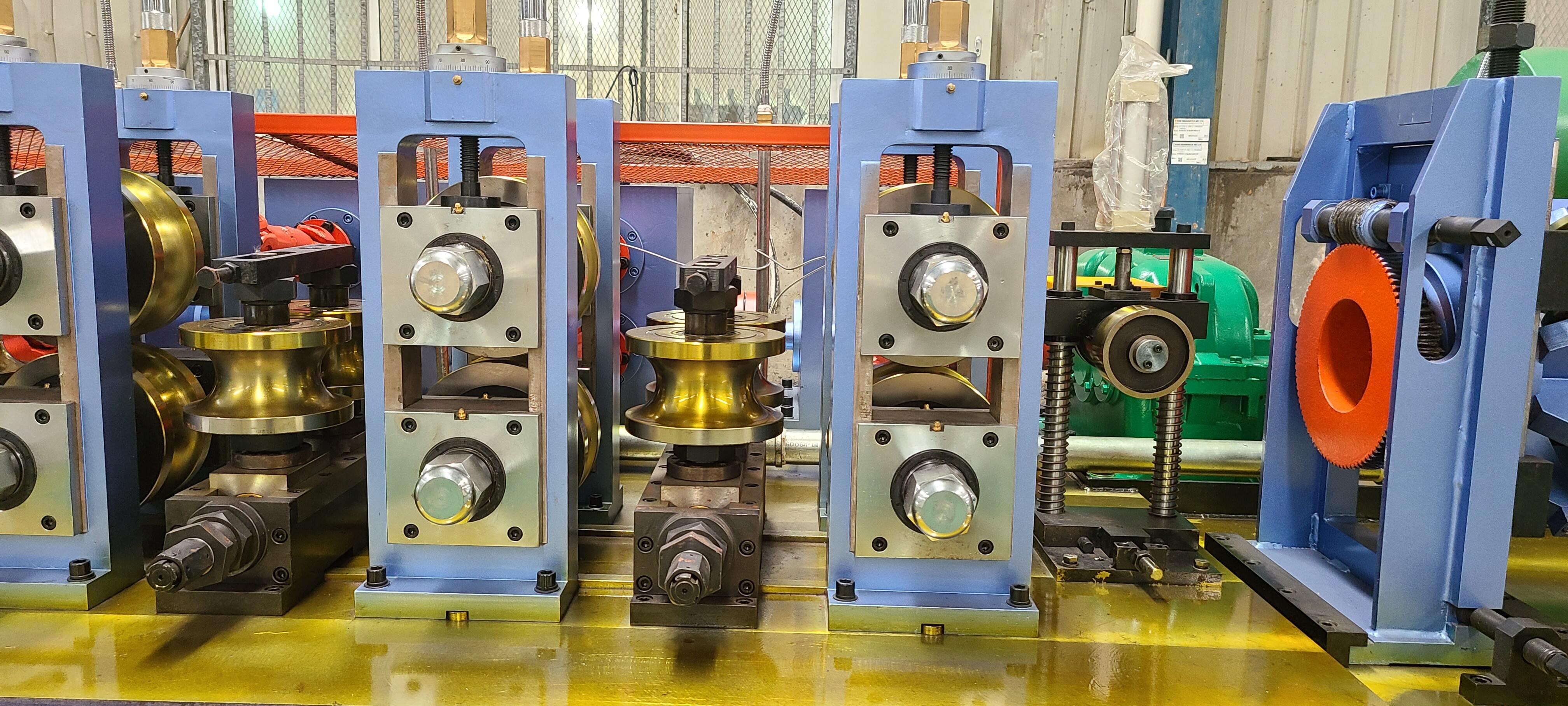

The automobile pipe making machine quotation encompasses a comprehensive manufacturing solution designed for producing high-quality automotive pipes with precision and efficiency. This advanced system integrates cutting-edge technology to deliver seamless production capabilities, featuring automated controls and multiple processing stations. The machine utilizes state-of-the-art forming technology to create pipes that meet strict automotive industry standards, with capabilities for various materials including steel, aluminum, and specialized alloys. The system includes precision cutting mechanisms, advanced welding stations, and quality control systems that ensure consistent output. It offers customizable settings for different pipe specifications, including diameter, wall thickness, and length, making it versatile for various automotive applications. The quotation covers the complete system package, including installation guidance, operational training, and warranty terms. With its robust construction and industrial-grade components, the machine guarantees long-term reliability and maintains high production efficiency. The integrated quality monitoring systems ensure that each pipe meets exact specifications, reducing waste and optimizing material usage.