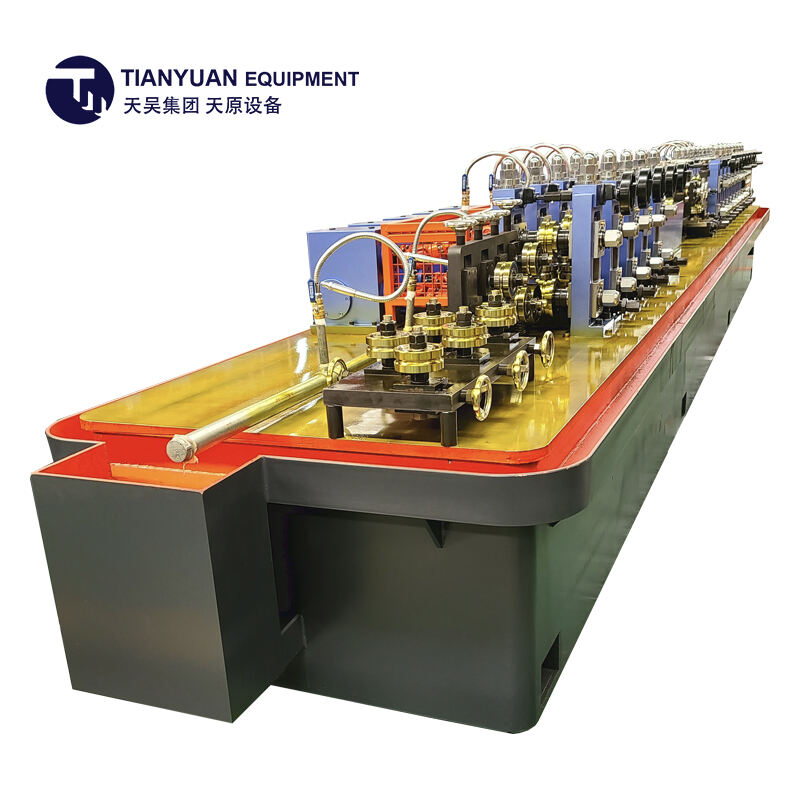

china steel pipe making machine

The China steel pipe making machine represents a cutting-edge solution in modern industrial manufacturing, designed to produce high-quality steel pipes with precision and efficiency. This sophisticated equipment integrates advanced automation technology with robust mechanical engineering to deliver consistent, reliable pipe production. The machine operates through a systematic process that begins with raw steel coil feeding, followed by precise forming, welding, and finishing stages. It features computerized control systems that ensure accurate dimensional control and superior weld quality. The machine can handle various steel grades and thicknesses, typically ranging from 0.5mm to 3.0mm, while producing pipes with diameters from 12mm to 76mm. Its versatility extends to manufacturing different pipe types, including round, square, and rectangular profiles, making it suitable for diverse industrial applications. The production line incorporates multiple quality control checkpoints, including ultrasonic testing and visual inspection systems, ensuring each pipe meets international standards. With production speeds reaching up to 120 meters per minute, depending on the model and specifications, these machines offer impressive output capacity while maintaining consistent quality. The technology also includes advanced safety features and energy-efficient systems, reflecting modern manufacturing requirements and environmental considerations.